8

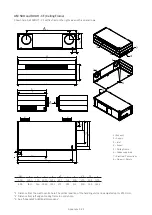

3.3. Installation of Wall Frames and the

Drilling of Duct Holes

NB! The air handling unit must be mounted on a solid

supporting base by using all possible attachment points.

If the wall itself is not sufficiently solid, the air handling

unit can be additionally fastened to the ceiling pursuant

to “Appendix 1 Dimensional Drawings’ and “Appendix 2

Additional Dimensions’.

NB! If the air handling unit is not properly affixed, there

is a high risk of the air handling unit disengaging from its

attachment fittings and falling down. This constitutes a

risk of damaging materials and/or causing serious personal

injury.

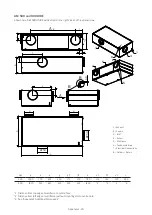

NB! The attachment material will depend on the supporting

base and the air handling unit and must be suitable for

properly supporting the unit’s weight of up to 257 kg on

the supporting base.

The wall to which the unit is fitted must have an even

surface. If the surface is too uneven, fitting of the frame

may be out of true. This may lead to leaks and an increased

noise level during operation of the unit.

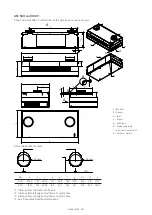

It is recommended that the duct holes be drilled 10-15 mm

larger than indicated on the drawings as this will allow for

subsequent insulation, will prevent direct contact with the

wall, and will allow for a vapour barrier etc. to be restored.

A rubber diaphragm for restoration of the function of the

vapour barrier is optional available and can be delivered

by Airmaster.

Duct holes in the wall must have an outward downward

gradient of 1-2% to prevent heavy rain from entering the

unit.

The holes for the roof ducts must be made oval to be able

to install the unit. “Appendix 1 Dimensional drawings’.

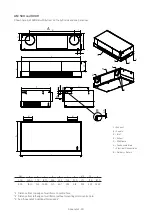

1. Hold the wall frame against the wall under the ceiling.

AM/AM+CC

150, 300

500, 800

Distance (A) wall frame

to ceiling [mm]

0

0

Optical air gap between

unit and ceiling [mm]

14

7,5

If the air gap (L) needs to be increased, e.g. if the unit is to

be installed with ceiling fittings (see also sections “Ceiling

Brackets” and “Appendix 2 Additional Dimensions”), distance

(A) should be increased.

2. Mark all holes and the top edge and left edge of

the wall frame on the wall.

Trial fit the wall frame

if necessary.