Before putting the compressor into

operation a few preliminary checks are to

be carried ut (please read carefully the

following instructions):

O

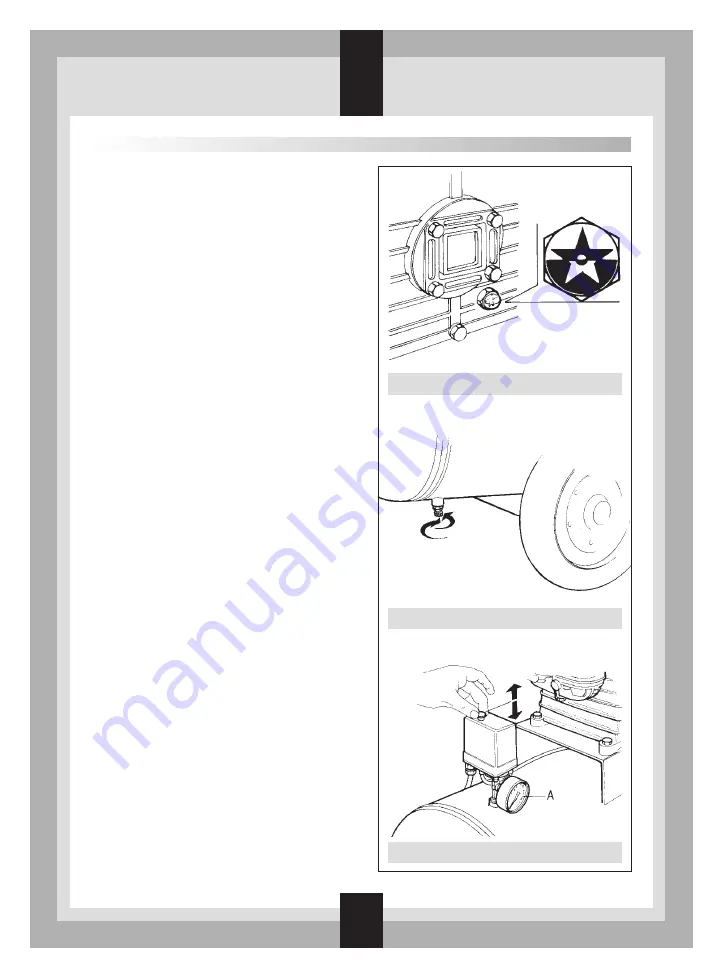

check the oil level of lubricated

compressors through the transparent

tap

(fig. 1), the red mark indicates the

ideal level (should the level differ from

normal, please read the instructions

under the title “Maintenance

Interventions”);

O

check that the condensation outflow tap

under the tank is closed

(fig. 2);

O

check that the red button on the air

pressure switch is in “OFF-0” position

(fig. 3).

To switch on the compressor pull the button

to “ON - 1” position (in three-phase motors

make sure that the working direction

corresponds to that shown on the red

arrow).

To switch off the compressor push the

button to “OFF - 0” position

(fig. 3).

To switch off the compressor always use

the button on the air pressure switch; if you

switch off the compressor through the

electric switch, the pressure in the head of

the compressor would be prevented from

being released, and this could cause

difficulties when using the compressor

again.

Do not pull the cable to unplug the

compressor and avoid placing the

compressor in too cold environments. It is

advisable not to use extensions of any kind

during normal operation of the compressor.

The functioning of the compressor is

adjusted by the air pressure switch, which

interrupts network supply when the pressure

inside the tank reaches the set value (10

bar) and reconnects the compressor to the

system when the pressure reaches a level

2 bar inferior to the set maximum level.

All the motors are provided with protection

FUNCTIONING

fig. 1

fig. 2

fig. 3

GB

Summary of Contents for CF 1010

Page 6: ...INSTALLAZIONE I...

Page 21: ...INSTALLATION GB...

Page 98: ...Notes...

Page 100: ...COD 007302120...