WARNING

For three-phase motors the working

direction is to be controlled. The

direction is indicated by a red arrow

attached to the belt cover.

CONNECTION

TO THE PNEUMATIC SYSTEM

The connection of the compressor to the

system of compressed air distribution

must

be carried out with the use of a flexible pipe,

minimum 60 cm long, and with an adequate

width to be properly connected to the

compressor.

For the correct functioning of the

compressor, it is necessary to connect the

compressor to a

closed or ring circuit

distribution system. This reduces load losses

to the minimum and allows for the

homogeneous distribution of compressed

air in the system.

The pipes are to be of appropriate size, free

of weldings (Mannesmann type) and made

of a plastic material adequate for working

with compressed air. If metal pipes are used,

make sure they have an inner galvanic

protection.

WARNING

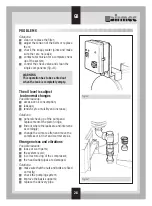

Use flexible pipes 1 1/2 times as wide

as the air outlet taps, since

consequent load losses might lead to

a reducttion in the power of the

compressor, and thus an increased

minimum working pressure might

compromise the global output of the

compressor.

Avoid narrowings of any kind in the

circuit; it is advisable to use elbow

joints with a long radius of curvature.

Provide the tank outlets and the

network with sluice valves for the

tapping of compressed air, which

allow for interventions along the line.

A connection to an emergency system

in case of malfunction of the main

compressor should be also provided.

The valves and the joints must have

a size adequate for the air outlet.

Position the air circuit with a 1%

gradient in order to allow

condensation settling on the bottom

of the tanks in the lowest parts of the

network to flow out.

Use automatic drainpipes or

discharging taps for standard models

for eliminating the condensation.

INSTALLATION

GB

21

Summary of Contents for HOBBY Series

Page 2: ......

Page 6: ...INSTALLAZIONE 6 I...

Page 20: ...INSTALLATION GB 20...

Page 64: ...007301996 D O C...