10

UVHEALTH BIO2000 Installation Manual

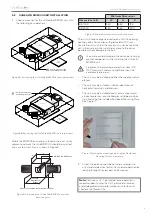

3. Install the UVHealth BIO2000 unit:

Never expose eyes or skin to UV-C light from any

source. Looking directly at the UV-C light may

cause permanent eye damage or blindness. Never

operate the UVHealth BIO2000 Air Purifying

System out of the plenum. Avoid touching the

glass portion of the lamp with your hands.

a. Remove two Phillips head screws on the left and

right hand side of the front electrical cover and

remove the cover

b. Hold or temporarily tape the included Ductboard

Mounting Plate in the location chosen for

installation, and using the plate as a template, mark

the mounting surface using the outermost slots in

the plate (see Figure 11). Alternatively, a 136.5 mm

square may be marked on the mounting surface.

c. Cut out the opening for the unit in the mounting

surface, making sure to cut slightly outside the

marked lines if the Ductboard Mounting Plate was

used as a template.

d. If mounting the unit on ductboard, attach the

Ductboard Mounting Plate to the opening by

folding the inner flaps of the plate into the opening

and fully back against the inside of the opening in

the ductboard, either from the sides or from top

and bottom of the plate. Finish the Ductboard

Mounting Plate installation by sealing around the

edges of the plate to the ductboard, using mastic

foil tape or other material suitable for sealing duct

joints.

e. Insert the unit into the duct opening and attach

it to the duct (or Ductboard Mounting Plate) with

the four included sheet metal screws. The wider

side of the V-shape of the UVHealth BIO2000 unit

panels should face into the oncoming airstream,

see Figure 12.

f.

The UVHealth BIO2000 models are configured for

upward or horizontal air flow direction as shipped. If

the direction of airflow in the duct is downward, the

whole unit may be rotated, so that airflow matches

Figure 12.

g. Reattach cover using two sheet metal screws

previously removed in step 3a.

h. Attach the quick connect power cord and plug in to

any standard electrical outlet.

i.

Verify lamp operation by looking through the view

port on front cover.

Figure 12: Unit showing direction of airflow

Figure 13: Unit showing lamp in operation