11

UVHEALTH BIO2000 Installation Manual

6.0 MAINTENANCE

Maintenance and service should only be completed by a

qualified technician.

Disconnect power to the unit before commencing

inspection and cleaning.

Never expose eyes or skin to UV-C light from any

source. Looking directly at the UV-C light may

cause permanent eye damage or blindness. Never

operate the UVHealth BIO2000 Air Purifying

System out of the plenum. Avoid touching the glass

portion of the lamp with your hands.

Note:

Wear disposable, non-absorbent protective

gloves prior to inspection procedure in case of accidental

breakage of glass.

•

We recommend inspecting and cleaning the lamp at

least every 6 months. Frequency depends upon the

environment. Such as: the type of air filter, duration

of use and replacement cycle.

•

To maintain maximum output intensity, replace

the lamp annually. The lamp should operate

continuously for maximum lamp life and light

effectiveness.

•

Do not attempt to clean the catalytic honeycomb

core with cleaning solutions. The catalyst is radiated

with short wave ultraviolet light during period of

non-air flow and is self-cleaning. If there is build up

blocking the catalytic cells, sit the unit on end, on a

flat surface, with electrical enclosure facing up. Use

low-pressure, compressed air to blow the surface of

the catalytic cells free of blockage.

6.1 CLEANING THE LAMP

Disconnect power to the unit before starting

replacement procedure.

Note:

Wear disposable, non-absorbent protective

gloves prior to replacement procedure in case of

accidental breakage of glass.

1. Unplug the quick disconnect power cord from the unit.

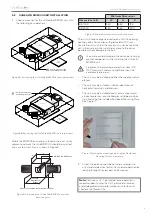

2. Remove two Phillips head screws on the left and right

hand side of the front electrical cover and remove the

cover.

3. Remove four mounting screws.

4. Remove the UVHealth BIO2000 body by sliding out of

the duct mounting plate.

5. Use a cotton cloth with isopropyl alcohol and gently

clean the surface of the lamp.

6. Replace the UVHealth BIO2000 back into the duct

mounting plate and tighten the mounting screws.

7. Replace the front electrical cover and plug the quick

connect power cord back into the unit mounting

screws.

6.2 REPLACING THE LAMP

• It is recommended the lamp is replaced after 12 months

of continuous service. To maintain maximum output

intensity, the lamp should be replaced annually.

• Replace only with a genuine replacement lamp. This

is a custom manufacture lamp designed only for the

UVHealth BIO2000 high output thermal compensating

electronic ballast.

• Follow the above steps and after step 4 loosen the

brass knurl nut on the clamp at the rear of the lamp.

Unplug the lamp electrical connector from the end

of the lamp shown in Figure 6 and gently slide the

lamp out the front of the UVHealth BIO2000 housing.

Reinstall by reversing the above steps.

Note:

If blue light leaks through any portion of plenum

and/or around mounting plate, unplug power supply

cord immediately and seal affected areas.

UV lamps contain a small amount of mercury,

like a typical fluorescent lamp. Check with your

local waste management authority for local

disposal or recycling requirements.

Never touch broken lamp or internal contents of

lamp. The lamp contains mercury.

Note:

In case of accidental exposure to internal

contents of lamp, wash hands and any other affected

skin area with mild detergent. Remove affected clothing

immediately. If skin surface is pierced, seek medical

attention immediately.

6.3 HONEYCOMB AND CARBON REPLACEMENT

If there is a need to replace the honeycomb or carbon

media, the following procedure should be followed.

Make sure power is disconnected from the unit

before removing the unit.

Note:

Wear disposable non-absorbent protective gloves

prior to replacement procedure in case of accidental

breakage of glass.

1. Unplug the quick disconnect power cord from the unit.

Look through the round sight glass hole and verify the

UV lamp is off before removing the unit. There should

be no blue glow along the length of the unit.

2. Remove the two Phillips head screws on the left and

right hand side of the front electrical cover and remove

the cover.