Page 70

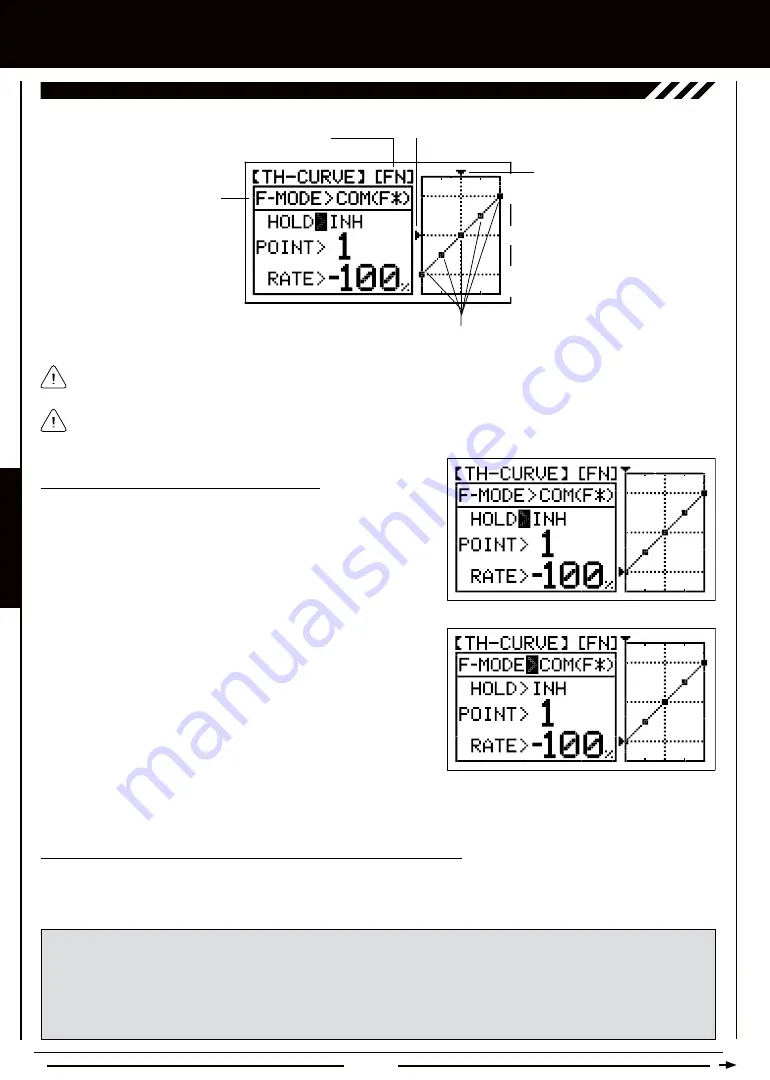

Choosing the Flight Mode - Common or Separate

1) From the Display screen, press the ENTER key to display the Programming

Menus.

2) Press the Navigation Pad

56

to highlight TH-CURVE, then press

the ENTER key to display the TH-CURVE menu. The cursor will

default to HOLD>INH.

3) Press the Navigation Pad

5

to move the cursor to F-MODE>COM.

4) Press the INC+/M1 or DEC-/M2 keys to choose either SEP OR COM

(SEParate or COMmon).

5) If you choose SEPARATE, press the F-MODE key to choose the F-MODE number you would like to program the Throttle

Curve function for. Choose from FN, F1 or F2.

hELi MODEL TyPE

Changing the Throttle Curve Point Values and the Rate Percentage Values

Five different Points with varying Rate percentage values can be programmed onto the Throttle Curve. Each Point will be

displayed on the graph to give you a visual interpretation of the position of the Point on the Throttle Curve. The Point that is currently

selected will flash.

WARNING

Keep in mind that it's possible to set the Rate percentage values higher or lower than the throttle End Point

Adjustment percentage values. For example, with the throttle High End Point Adjustment percentage value set to 100% and

POINT>5 Rate percentage value set to 150% the servo will move 150%.

We strongly recommend that you set the Throttle Curve Point Rate percentage values no higher than your throttle End Point

Adjustment percentage values unless specifically necessary for your particular setup. This will prevent any chance of overdriving

your control linkage.

Transmitter F-MODE refers to the Flight Mode that the transmitter is currently operating in. Programming F-MODE refers

to the Flight Mode that you would like to change the programming for.

Transmitter F-MODE

Programming F-MODE

Stick Input

Function Output

150%

100%

100%

150%

0%

Point Positions

As you change the Point values and Rate percentage values, you can use the graph and Input and Output indicators to

visualize the ratio between control stick movement and servo travel throughout the entire deflection range.

16.Th-cURvE (ThROTTLE cURvE), cOnTinUED....

Summary of Contents for SD-6G

Page 1: ...Page 1...