AirVerter

®

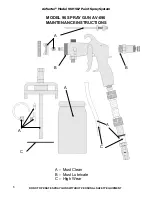

Model 96 HVLP Paint Spray System

DO NOT OPERATE SPRAY GUNS WITHOUT PERSONAL SAFETY EQUIPMENT

4

E.

Ensure needle packings are properly

adjusted

. Needle packings are preset at the

factory to proper tension. However, use and

cleaning may alter this setting. To adjust

needle packings to proper tension:

1. With gun disconnected from air and fluid

sources, pull trigger to move the needle out

of the nozzle.

2. Adjust packing nut until needle is held in the

open position by tension from the needle

packings.

3. Loosen packing nut approximately ¼ turn or

until needle returns to closed position.

Spraying

A. Air pressure forces paint from the paint

container into the fluid chamber of the gun

and out through the nozzle where the flow of

atomizing air breaks the paint stream into tiny

particles, creating the spray.

1. Needle position controls the amount of paint

flowing through the fluid nozzle.

2. Trigger action controls needle position.

3. The Fluid Control Knob at the rear of the

spray gun controls trigger action. Turning

the knob to the right will reduce the fluid

flow, turning it to the left increases the flow.

B. Adjust the pattern by turning the Pattern

Control Knob on top of the Spray Head. This

knob has a 90-degree range (full fan to round).

1. Round Pattern - used to draw fine lines with

the gun close to the work, for touch-up work,

camouflage patterns and painting surfaces

in difficult to reach places distant from the

spray gun. This pattern is achieved by

turning the Pattern Control Knob crosswise

the gun.

2. Full Fan Pattern - used with the spray gun

6"-8" from the work. Overlap not more than

50% of the previous pass. Do not “fog”

coat. This pattern is achieved by turning the

Pattern Control Knob so that it points toward

the handle.

3. The full fan pattern may be reduced in size

by gradually turning the Pattern Control

Knob crosswise the gun.

Fluid flow

must

be

reduced

at the same time to maintain

even paint distribution.

C. If you are having problems with the operation

of your paint gun, check the Trouble Shooting

Guide at the end of the manual for possible

causes and solutions.

AIR AND PAINT MANAGEMENT GUIDELINES

Approximate PSI

Application

Thin Coatings

ZAHN #2 Test: 16 to 22 seconds

Minimum 40 PSI compressor pressure

Machines and implements, small parts, plant maintenance,

controlled production work, work in enclosed areas with

poor ventilation, priming.

Thin to Medium Coatings

ZAHN #2 Test: 22 to 30 seconds

40 to 60 PSI compressor pressure

Dual gun work for all of the above listed applications - will

support up to 50' of 3/8" ID hose for each gun. Also for

higher production levels of all of the above.

High Solid Coatings

ZAHN #3 Test: 37 + seconds

50 to 70 PSI compressor pressure

Marine epoxies, marine enamels, high production

steelwork, high production with conveyer lines, large

surfaces with thinner viscosity material, latex on wood or

metal.

80% Solids Coatings

60 to 80 PSI compressor pressure

Ultra high production levels on extremely large surfaces;

un-thinned epoxies, enamels, latex, urethane.

Summary of Contents for AV-096

Page 12: ......