AirVerter

®

Model 96 HVLP Paint Spray System

DO NOT OPERATE SPRAY GUNS WITHOUT PERSONAL SAFETY EQUIPMENT

5

WARNING

Gun must be de-pressurized prior to any maintenance or disassembly

procedure. Disconnect all air and fluid hoses prior to performing any

maintenance operation.

CLEANING

Cleaning the Model 96 Spray Gun

Thorough removal of paint after each use is

ESSENTIAL

to the optimum operation of your

gun.

1. Using small amounts of solvent, repeatedly

flush the gun until all paint is removed and the

solvent runs clear.

2. Clean the exterior of the gun and cup with a

solvent-dampened cloth.

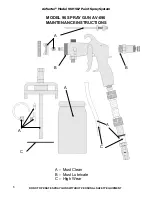

3. Remove the needle, nozzle and air cap and

clean them with a brush and solvent.

4. Check to see that all paint residue is removed

from inside the nozzle. Paint build-up here can

reduce fluid flow and prevent the needle from

seating properly causing leakage during

subsequent use.

5. Check the air passages in the air cap. Paint

build-up here reduces air flow and will result in

a distorted pattern.

6. Clean the packings at the rear of the fluid

block with a brush and solvent. Improperly

cleaned packings can cause the needle to

stick, resulting in poor performance of the gun.

If using a gun washer, place the Gun in the

cleaner and cycle. Then follow instructions above

making sure all parts are clean and dry before re-

assembly.

SPRAY GUN PERFORMANCE IS DIRECTLY RELATED TO

HOW WELL THE GUN IS CLEANED AFTER USE

Cleaning Ancillary Equipment

A. If using a 1-Quart Cup, be sure to clean the

Air Pressure Tube of all paint residue.

B. Clean the anti-drip feature on the cup lid and

be sure this air passage is open.

C. Clean all paint residue from the cup, with

particular attention to the gasket and cup lip.

(

Hint

: Periodically turning the gasket over

prolongs gasket life.)

D. Clean or replace the filter on the Inductor to

maintain proper airflow through the system.

Lubricate

A. Use Vaseline or a non-silicone grease to

lubricate the gun.

B. Lubricate all threaded connections for ease

of maintenance.

C. Lubricate the Needle only where it passes

through the needle packings.

D.

DO NOT

allow lubricant to get into the Fluid

Tube, Nozzle, Air Cap, or interior of the paint

chamber (areas where paint may come in

contact with lubricant).

WEAR ITEMS

A. Replace Fluid Needle and Nozzle when the

Needle extends 3/32

″

beyond the Nozzle.

Unscrew the Fluid Regulating Assembly

being careful not to lose the Needle Tension

Spring. Remove Needle and replace.

B. Replace the inductor filter on the AirVerter

®

Inductor when it becomes clogged and can

no longer be cleaned. A filter must be used

to prevent dust and dirt from being blown

onto the finish.

Summary of Contents for AV-096

Page 12: ......