CONTROL SYSTEM

11-6

SM TELECOM 1-A.0 GB

11.3 General

Functions

11.3.1

COMP Operation

a. For each Mode including POWER OFF & SB, a Min time delay of 3 min before

COMP restarting, excluding DEICING Mode (see para.

14.12.2

).

b. The Min operation time of COMP under different operating conditions is:

Operation Mode

Min Operation Time of COMP

Heat, Cool, HP protection or Auto Modes

3 min.

Fan, Dry, Overflow, Protection Modes, or Mode Change

Ignored

11.3.2

IFAN

operation

a. Min time interval between IFAN speed change in AUTOFAN Mode is 30 sec.

b. Min time interval between IFAN speed change in H/M/L Mode is 1 sec.

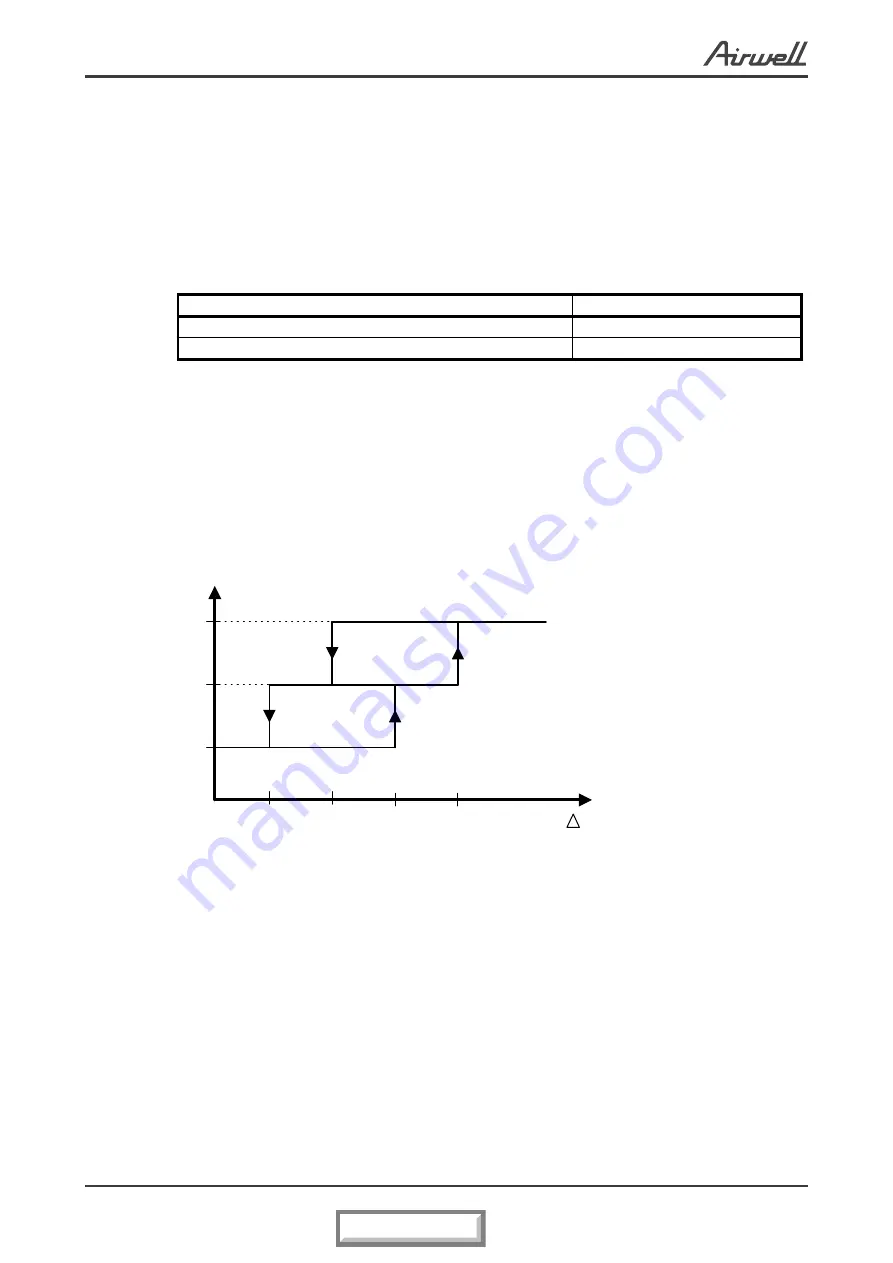

c. IFAN speed in Heat/Cool AUTOFAN Mode is determined according to the

following chart:

T [

o

c]

L

M

H

IFAN speed

3

1

4

2

Where in Heat Mode:

'

T = SPT - RT

in Cool Mode:

'

T = RT- SPT

11.3.3 OFAN

Operation

Min time interval between OFAN ON/OFF state changes is 30 sec.

11.3.4 HE

Operation

a. Min Heaters ON or OFF time is 30 sec.

b. Heaters can never be in operation while IFAN is OFF.

c. In RH group, HE-1 and HE-2 will be activated only when COMP is not operating,

except in Dry Mode.

CONTENTS

Summary of Contents for GC 12 LT

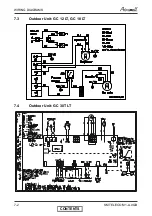

Page 13: ...OUTLINE DIMENSIONS 4 3 SM TELECOM 1 A 0 GB 4 5 Outdoor Unit GC 30T LT CONTENTS...

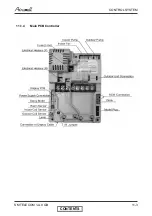

Page 28: ...CONTROL SYSTEM 11 3 SM TELECOM 1 A 0 GB 11 1 4 Main PCB Controller CONTENTS...

Page 70: ...EXPLODED VIEWS SPARE PARTS LISTS 13 6 SM TELECOM 1 A 0 GB 13 6 Outdoor Unit GC 12 LT CONTENTS...

Page 72: ...EXPLODED VIEWS SPARE PARTS LISTS 13 8 SM TELECOM 1 A 0 GB 13 8 Outdoor Unit GC 18 LT CONTENTS...

Page 87: ...APPENDIX A 15 1 SM TELECOM 1 A 0 GB APPENDIX A INSTALLATION AND OPERATION MANUAL CONTENTS...