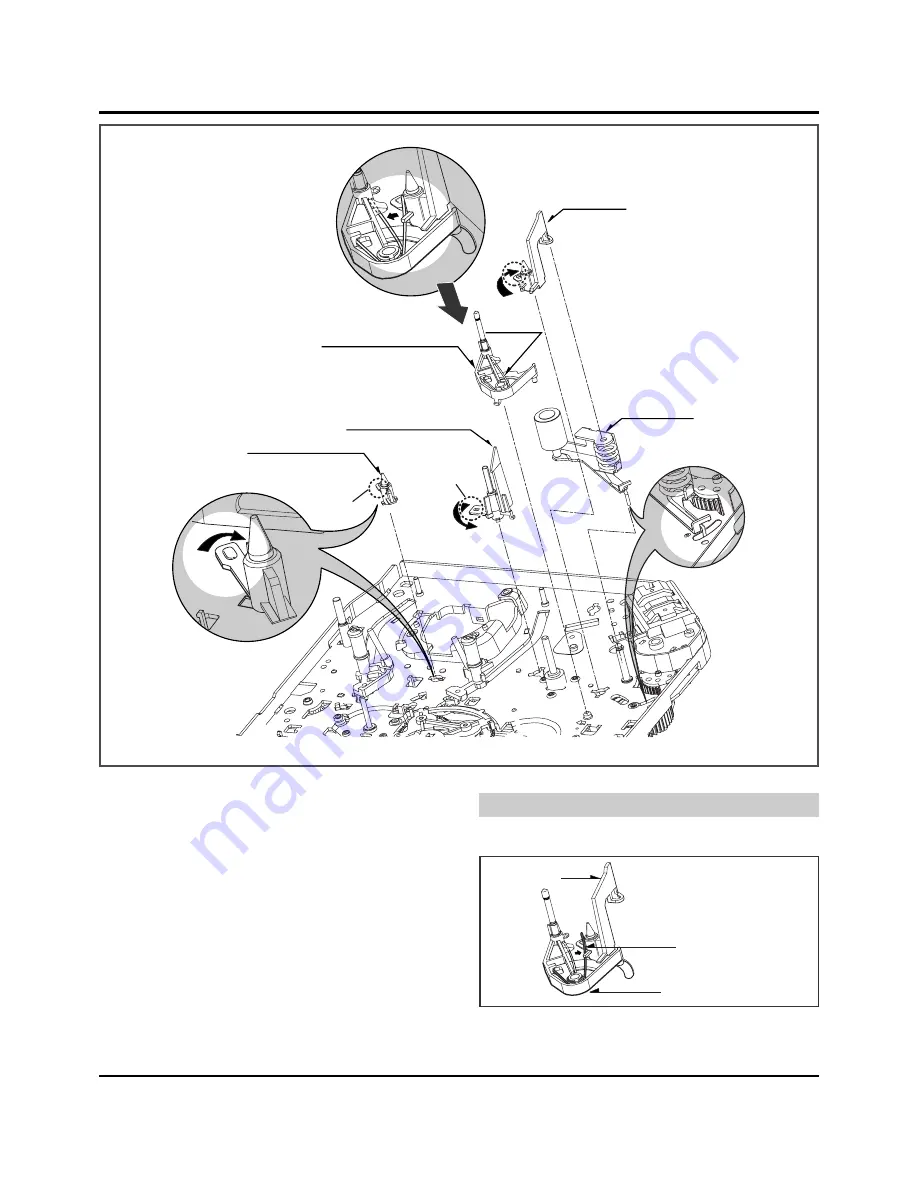

DECK MECHANISM DISASSEMBLY

Arm

Assembly

Pinch

Opener Lid

Base Assembly P4

Support CST

Arm Assembly T/up

(A)

(B)

(C)

(D)

Spring

Arm T/Up

Fig. A-5

54

15. Support CST (Fig. A-5-1)

1) Break away the (A) part shown above Fig. A-5-1 from the

Embossing of the Chassis in the clockwise direction, and

lift up the Support CST.

16. Base Assembly P4 (Fig. A-5-2)

1) Break away the (B) part shown above Fig. A-5-2 from the

Embossing of the Chassis in the counterclockwise direc-

tion and lift up the Base Assembly P4.

17. Opener Lid (Fig. A-5-3)

1) Hook the Spring Arm T/up on the Split digged under the

Arm Assembly T/up.(Refer to Fig.A-5-4(D)).

2) Break away the (C) Part of the Opener Lid from the

Embossing of the Chassis in the Clockwise direction and

lift up the Opener Lid.

18. Arm Assembly T/up (Fig. A-5-4)

1) Confirm that the Spring Arm T/up is placed as above

(No.17.1).

2) Lift up the Arm Assembly T/up.

(1) When reassembling, unhook the Spring Arm T/up Shown

above (No.17.1) to the original position.

19. Arm Assembly Pinch (Fig. A-5-5)

1) Lift up the Arm Assembly Pinch.

NOTE

Opener Lid

Spring Arm T/up

Arm Assembly T/up

(Fig. A-5-3)

(Fig. A-5-4)

(Fig. A-5-1)

(Fig. A-5-2)

(Fig. A-5-5)