SERVICE MANUAL

DA

TA

COLOR TELEVISION

TV-AN2110

NH

S/M Code No. 09-002-419-1S1

SUPPLEMENT

•

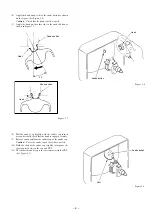

This Service Manual contains the additional information

“NOTICES BEFORE REPAIRING”, “DISASSEMBLY INSTRUCTIONS”

and “ADJUSTMENT” for the model TV-AN2110 (NH).

If requiring the other information, see Service Manual of

TV-AN2110 (NH), (S/M Code No. 09-99B-419-1R1).