– 31 –

< TUNER SECTION >

1. Clock Frequency Check

Settings :

• Test point :

TP2 (CLK)

Method :

Set to MW 1602kHz and check that the test point is

2052kHz

±

45Hz.

2. MW VT Check

Settings :

• Test point :

TP1 (VT)

Method :

Set to MW 1602kHz and check that the test point is

less than 8.0V. Then set to MW 531kHz and check

that the test point is more than 0.6V.

3. MW Tracking Adjustment

Settings :

• Test point :

TP8 (Lch), TP9 (Rch)

• Adjustment location : L981 (1/3)

Method :

Set to MW 999kHz and adjust L981 (1/3) so that the

test point becomes maximum.

4. LW VT Adjustment

Settings :

• Test point :

TP1 (VT)

• Adjustment location : L942

Method :

Set to LW 144kHz and adjust L942 so that the test

point becomes 1.3V

±

0.05V.

Then set to LW 290kHz and check that the test point

is less than 8.0V.

5. LW Tracking Adjustment

Settings :

• Test point :

TP8 (Lch), TP9 (Rch)

• Adjustment location :

L941 ........................... 144kHz

TC942 ......................... 290kHz

Method :

Set up TC942 to center before adjustment. The level at

144kHz is adjusted to MAX by L941. Then the level

at 290kHz is adjusted to MAX by TC942.

6. AM IF Adjustment

Settings :

• Test point :

TP8 (Lch), TP9 (Rch)

• Adjustment location :

L772 ........................... 450kHz

7. FM VT Check

Settings :

• Test point :

TP1 (VT)

Method :

Set to FM 108.0MHz and check that the test

point is less than 8.0V. Then set to FM

87.5MHz and check that the test point is more than

0.5V.

8. FM Tracking Check

Settings :

• Test point :

TP8 (Lch), TP9 (Rch)

Method :

Set to FM 98.0MHz and check that the test point is

less than 13dB

µ

V.

9. DC Balance / Mono Distortion Adjustment

Settings :

• Test point :

TP3, TP4 (DC balance)

• Adjustment location : L771

• Input level :

60dB

µ

V

Method :

Set to FM 98.0MHz and adjust L771 so that the

voltage between TP3 and TP4 is 0V

±

0.04V. Then

check the distortion is less than 1.3%.

10. Output Level Check

<MW>

Settings :

• Test point :

TP8 (Lch), TP9 (Rch)

• Input level :

74dB

µ

V

Method :

Set to MW 999kHz and check that the test point is

50mV

±

3dB.

<FM>

Settings :

• Test point :

TP8 (Lch), TP9 (Rch)

• Input level :

60dB

µ

V

Method :

Set to FM 98.0MHz and check that the test point is

220mV

±

3dB.

11. FM Separation Check

Settings :

• Test point :

TP8 (Lch), TP9 (Rch)

• Input level :

60dB

µ

V

Method :

Set to FM 98.0MHz and check that the test point is

more than 12dB.

Summary of Contents for XR-HG5MD

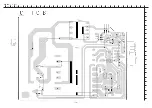

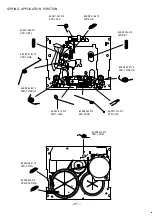

Page 14: ...SCHEMATIC DIAGRAM 1 MAIN 1 2 AMP SECTION 14 ...

Page 15: ...SCHEMATIC DIAGRAM 2 MAIN 2 2 TUNER SECTION 15 ...

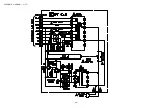

Page 18: ...SCHEMATIC DIAGRAM 3 FRONT 18 ...

Page 20: ...SCHEMATIC DIAGRAM 4 PT 20 ...

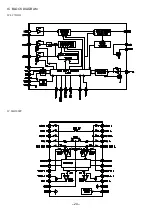

Page 24: ... 24 IC BLOCK DIAGRAM IC LC72131D IC M61500FP ...

Page 25: ... 25 IC BU2092F IC BA3835F ...

Page 26: ... 26 IC LA1837NL IC BU2099FV ...

Page 27: ... 27 IC BU1920FS ...

Page 28: ... 28 FL HNA 13MM14T GRID ASSIGNMENT ANODE CONNECTION GRIDASSIGNMENT ...

Page 29: ... 29 ANODECONNECTION ...