28

8

3

7

L771

L772

TP1

4

L981

FFE801

TP2

R785

30

IC771

TP4

TP3

TP6

GND

TP5

CN701

12

11 10

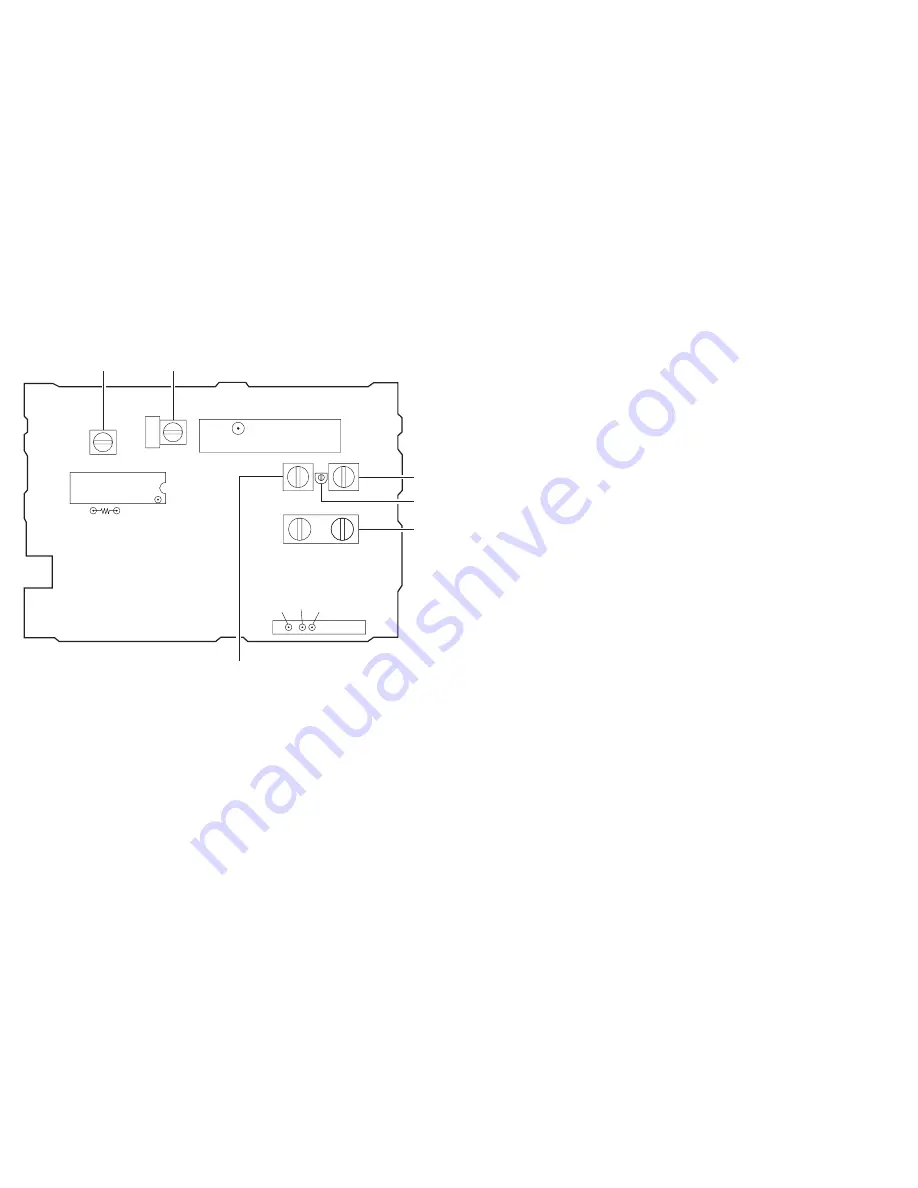

TUNER C.B

4

6

L942

L941

TC942

7

ELECTRICAL ADJUSTMENT

< TUNER SECTION >

< FM SECTION >

IHF Sensitiviy:

Less than 13dB

(THD 3%)

(at 108.0/98.0MHz)

Less than 14dB

(at 98.0MHz)

Distortion:

Less than 1.2% (98.0MHz)

Stereo separation:

More than 12dB (98.0MHz)

Intermediate frequency:

10.7MHz

< MW SECTION >

Sensitivity:

Less than 60dB (at 600kHz)

(S/N 20dB)

Less than 58dB

(at 1000/1400kHz)

Distortion:

Less than 1.5%

(at 1000kHz)

< LW SECTION >

Sensitivity:

Less than 70dB (at 144kHz)

Less than 68dB (at 198kHz)

Less than 66dB (at 290kHz)

PRACTICAL SERVICE FIGURE

< TUNER SECTION >

1. Clock Frequency Check

Settings:

•

Test point: TP2 (CLK IC770 pin30)

Method:

Set to MW 1602kHz and check that the test

point becomes 2052kHz±45Hz (EZ).

2. MW VT Check

Settings:

•

Test point: TP1 (VT)

Method:

Set to MW 1602kHz and check that the test

point is less than 8.0V.

Then set to MW 531kHz and check that the

test point is more than 0.6V.

3. MW IF Adjustment

Settings:

•

Test point: TP5, TP6

L772 .............................................. 450kHz

4. MW Tracking Adjustment

Settings:

•

Test point: TP5, TP6

•

Adjustment location: L981

Method:

Set to MW 999kHz and adjust L981 so that the

test point becomes maximum.

5. FM VT Check

Settings:

•

Test point: TP1 (VT)

Method:

Set to FM 87.5MHz, 108.0MHz and check that

the test point is more than 0.5V (87.5MHz) and

less than 8.0V (108.0MHz).

6. LW VT Adjustment

Settings:

•

Test point: TP2 (VT)

•

Adjustment location: L942

Method:

Set to LW 144kHz and adjust L942 so that the

test point becomes 1.3V±0.05V.

Then set to LW 290kHz and check that the test

point is less than 8.0V.

7. LW Tracking Adjustment

Settings:

•

Test point: TP5, TP6

•

Adjustment location:

L941 .............................................. 144kHz

TC942 ........................................... 290kHz

Method:

Set up TC942 to center before adjustment.

The level at 144kHz is adjusted to MAX by

L941. Then the level at 290kHz is adjusted to

MAX by TC942.

8. DC Balance/Mono Distortion Adjustment

Settings:

•

Test point: TP3, TP4

•

Adjustment location: L771

•

Input level: 54dB

Method:

Set to FM 98.0MHz and adjust L771 so that

the voltage between TP3 and TP4 becomes

0V±0.04V.

Next, check that the distortion is less than

1.3%.

27

Summary of Contents for XR-MD200

Page 6: ...6 DISASSEMBLY INSTRUCTIONS 1 Remove the two screws 2 Remove the two screws 1 2 ...

Page 13: ...14 13 BLOCK DIAGRAM IC301 LC866532A ...

Page 14: ...1 2 3 4 5 6 7 8 9 10 11 12 13 14 A B C D E F G H I J K 16 15 WIRING 1 POWER AMP AC 230V 50Hz ...

Page 15: ...18 17 SCHEMATIC DIAGRAM 1 POWER AMP Q261 262 MUTE R261 22k R262 22k 220k 220k 1000p 1000p ...

Page 16: ...1 2 3 4 5 6 7 8 9 10 11 12 13 14 A B C D E F G H I J K 20 19 WIRING 2 FRONT ...

Page 17: ...22 21 SCHEMATIC DIAGRAM 2 FRONT IC301 LC866532A 5L31 ...

Page 28: ...40 39 BLOCK DIAGRAM 1 CD ...

Page 29: ...42 41 BLOCK DIAGRAM 2 MD TO MAIN C B CN502 TO CD C B CN6 ...

Page 30: ...44 43 WIRING 1 CD 14 13 12 11 10 9 8 7 6 5 4 3 2 1 A B C D E F G H I J CD C B COMPONENT SIDE ...

Page 31: ...46 45 1 2 3 4 5 6 7 8 9 10 11 12 13 14 A B C D E F G H I J TP3 CD C B CONDUCTOR SIDE ...

Page 32: ...48 47 SCHEMATIC DIAGRAM 1 CD 1 2 DTC114TK ...

Page 33: ...50 49 SCHEMATIC DIAGRAM 2 CD 2 2 RESET 5M36 ...

Page 34: ...1 2 3 4 5 6 7 8 9 10 11 12 13 14 A B C D E F G H I J K 52 51 WIRING 2 FUNCTION ...

Page 35: ...54 53 SCHEMATIC DIAGRAM 3 FUNCTION ...

Page 59: ...81 IC BA5936 Rog CURRENT DETECTOR TERMINAL IC BA5970FP IC BA6417F ...

Page 60: ...82 IC BD7910FV IC AK4519VF ...

Page 72: ...931196 Printed in Singapore 2 11 IKENOHATA 1 CHOME TAITO KU TOKYO 110 JAPAN TEL 03 3827 3111 ...