600mm

3

|

01252 359760 • ajproducts.co.uk

8. OIL AND LUBRICANT RECOMMENDATIONS

The high-lift pallet truck, with forks for independent lifting of loads, is intended

for on-site transporting of unit loads, e.g. in warehouses associated with industry

and delivery companies etc., for short range transporting of standard and wire

mesh pallets as well as other palletised loads.

Additionally, the high-lift pallet truck can be made stationary as a working

platform. (Automatic supports are placed once a lift of 400 mm is reached).

It is not suitable for use in potentially .

Battery loading

Battery should be loaded as soon as lifting speed is slowing down, and/or

green diode is dark. The loading is starting automatically, the red

diode is on.

The loading is finished when 8 to 10 diodes (including the red diode) of the

discharge indicator is on. When loading is done the green pilot lamp is on.

The electric high-lift pallet truck can be taken into operation again.

The loading time is about 10 to 12 hours while the machine cannot be used.

Never leave the built-in charger longer than 24 hours connected. Never

discharge the battery totally (max. discharge 80%), this could damage the

battery or even render it useless.

Safety warning

Before inspection andmaintenance work is carried out, appropriate

measures should be taken to remove all loads from the electric high-lift

pallet truck.

Hydraulic oil: ISO VG 46

Lubricant: Multipurpose lubricating grease for example: ARAL Aralub 2, BP

Multipurpose lubricating grease L2, Energrease LS 2, ESSO Beacon 2

The oil level should be checked every six months. The following oil types are to

be used depending on the temperature conditions.

5. INSPECTION AND MAINTENANCE INSTRUCTIONS

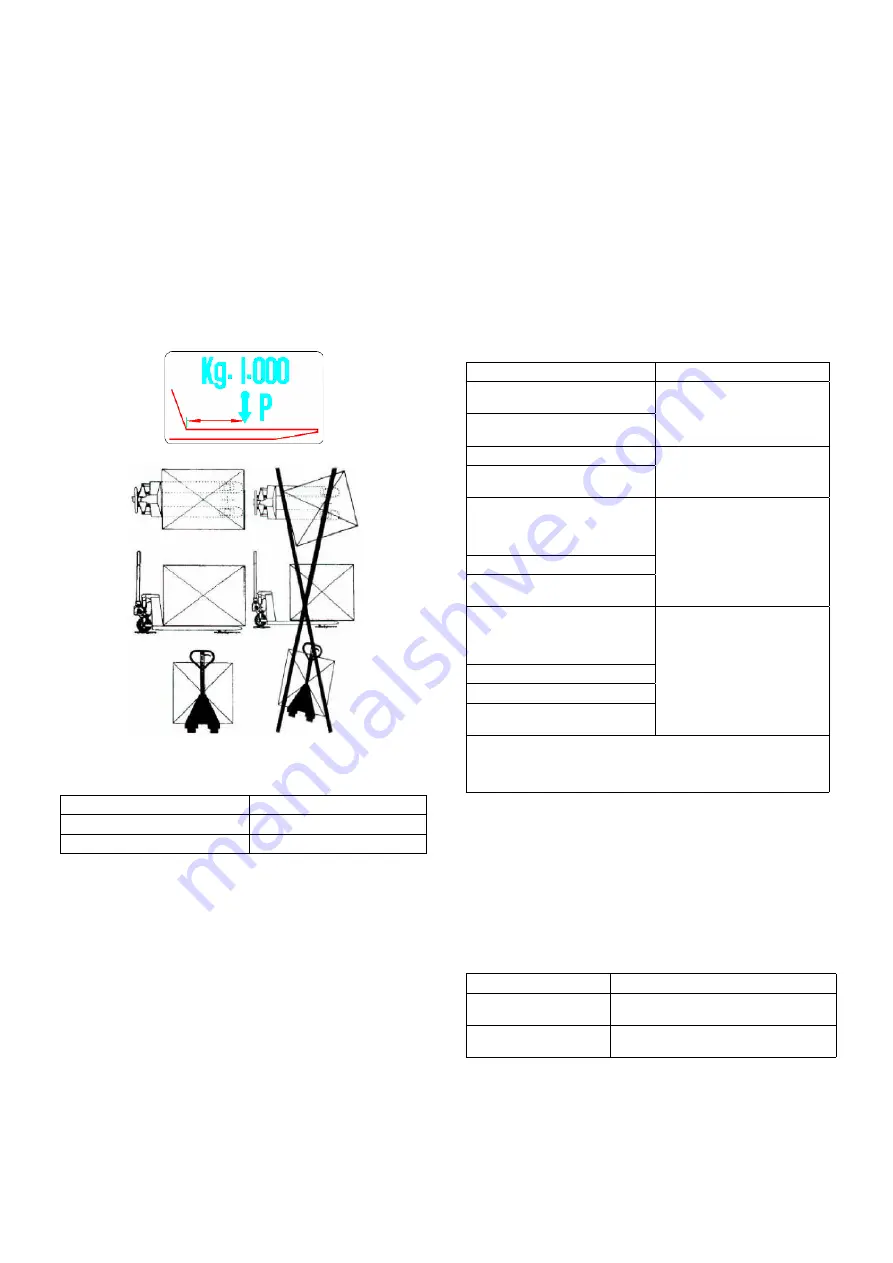

6. LOADING DIAGRAM

The load center must not be exceeded.

Danger of Tipping over!

The load must be evenly distributed across both prongs of the forks.

7. BATTERY AND CHARGER

Battery voltage

12V / 70Ah

Max charging current of charger

8A

Input/Output voltage of charger

AC220V / DC 12V

Recommendations for security in relation with the acid of the battery. The pallet

truck should be put out of function before working on the battery.

Service people:

Read carefully the instructions of use and maintenance, given by the company

manufacturing the battery.

Maintenance of the battery:

Be sure pole terminals and cable lug of battery are clean and covered slightly

with grease and tightened.

Do not retain discharged batteries. Recharge as soon as possible.

Avoid heavy discharge of more than 80% of nominal capacity.

Disposal of the battery:

Please follow carefully national laws and recommendations concerning

protection of environment of your country. Also follow battery manufacturer

recommendations on this purpose.

Maintenance and inspection work

Inspection intervals

Check operating elements for fault-

less operation.

Daily or each time before use

Check condition of the travelling rol-

lers and roller axles

Grease joints and bearings

Monthly

Check functioning of wheels and

rollers

Check hydraulic system for leakage

(Is the top lifting height

reached effortlessly?)

Every 3 months

Check the set-up of the drain valve

Check all screw and bolt connections

for tightness

Check all parts of the pallet truck for

wear and replace defective

parts where necessary

Annually

Change oil in the hydraulic system

Check readability of type plate.

Authorize inspection by competent

technical expert

The service life of your high-lift pallet truck is limited.

Worn parts must be renewed in adequate time.

Temperature

Oil

-5°C – approx. +45° C

L-HL 68 Hydraulic oil (equivalent to ISO

VG68)

-15°C - approx. - 5° C

L-HL 46 Hydraulic oil (equivalent to ISO

VG46)

Waste oil must be disposed of in accordance with legal provisions!