2

|

01252 359760 • ajproducts.co.uk

Note:

Do not attempt to repair the truck unless you are trained and authorized.

4. MAINTENCE

4.1 Hydraulic oil

Please check the oil level every six months. The oil can be hydraulic oil: ISO VG

32(GB11118-89), its viscosity should be 32cSt at 40, total volume is about 4.Olt.

4.2 Daily check and maintenance

It is necessary to check the truck daily. Special attention should be paid to the

rollers, the axles, as thread, rags, etc., it may block the rollers; the scissors

and the table should be checked, they may be deformed; the table should be

unloaded and lowered in the lowest position when the job is over.

4.3 Lubrication

Use motor oil or grease to lubricate all movable parts.

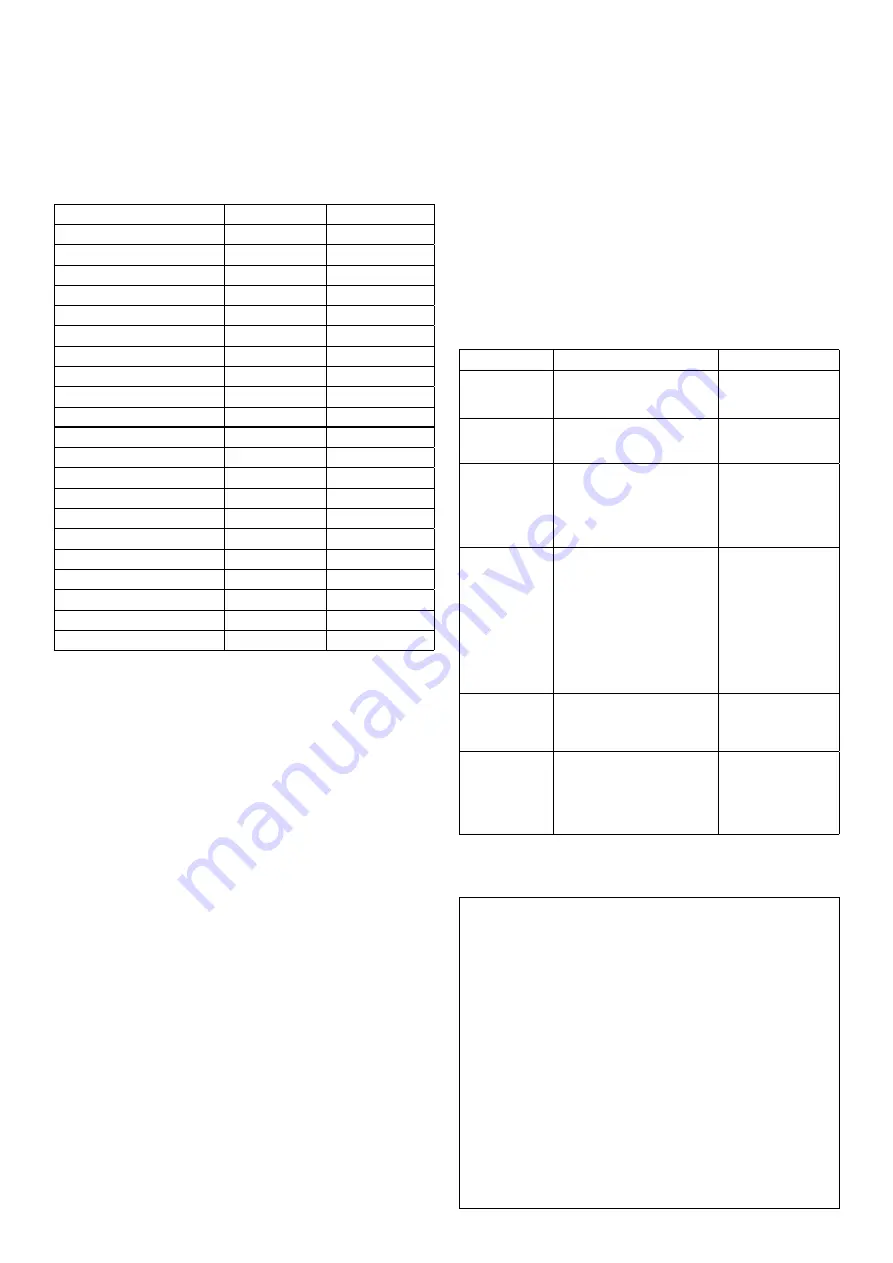

5. TroubLEsHooTINg

Trouble

Clause

Fixing methods

The table can

not be up the

max. height

- The hydraulic oil is not enough

- The position of the travel

switch

- Pour in the oil

- Adjust the position of

travel switch

The table can

not lift.

- Without hydraulic oil.

- Safety valve has no enough

pressure.

- Pour in the oil

- Adjust the safety

valve

The motor can-

not run

- The emergency switch is

turned off

- The connection of electrical

wire is loose.

- The contactor of DC motor is

damaged.

- Turn the emergency

switch clockwise;

- Tight it;

- Replace it with a

new one

The table cannot

descend

- The piston rod or cylinder is

deformed resulting from partial

loading slanting to one side or

over-loading.

- The fork was kept in the high

position for long time, which

cause piston rod bared to

arise in rusting and jamming

of the rod.

- The release valve of pump can

not work because of abrasion

- Replace the piston

rod or cylinder with

new one

- Keeping the fork in

the lowest position if

not using, and pay

more attention to

lubricate the piston

rod.

- Replace with new

one

Leaks

- Sealing parts worn or dama-

ged.

- Some parts cracked

- Replace with

new one

- Replace with

new one

The fork de-

scends without

the release valve

worked

- The impurities in the oil cause

the release valve to be unable

to close tight.

- Sealing parts worn or

damaged.

- The release valve is damaged.

- Replace with new oil

- Replace with new

one

- Replace with new

one

Welcome to use our electrical lift table. This lift table is made

of high quality steel and is designed to give a durable, reliable

and easy to use. For your safety and correct operation, please

carefully read this instruction and warnings on the lift table

before using it.

1. sPECIFICATIoNs

Type

HIW1.0Eu

HIW2.0Eu

Capacity

500 kg

1000 kg

Max. height

1010 mm

1010 mm

Min.height

190 mm

190 mm

Dimension of the table

1300 x 800 mm

1300 x 800 mm

Lifting speed

15 s

26 s

Lower speed

13 s

20 s

Pump electric current

3 l/min

3 l/min

Oil tank

2 l

2 l

Pump station

AC3 x 380V, 750W

AC3 x 380V, 750W

Weight

160 kg

220 kg

Type

HIW4.0Eu

HIW3.0Eu

Capacity

2000 kg

3000 kg

Max. height

1010 mm

1020 mm

Min.height

190 mm

220 mm

Dimension of the table

1300 x 800 mm

1300 x 800 mm

Lifting speed

40 s

26 s

Lower speed

30 s

22 s

Pump electric current

3 l/min

5 l/min

Oil tank

3 l

3 l

Pump station

AC3 x 380V, 750W

AC3 x 380V, 1500W

Weight

280 kg

320 kg

2. sAFETY guIDANCE

2.1

Operator should read all warning signs on the truck and instructions here

before using it.

2.2

Do not put foot and hand under the scissors, injury could happen.

2.3

Do not enter under table.

2.4

Do not overload.

2.5

Do not use it on slope, lift table may become uncontrollable and create

danger.

2.6

Do not lift persons. People could fall down and suffer severe injury.

2.7

Do not side or end load .Load must be distributed on at least 80% of the

table area

2.8

The table should be maintained by the professional operator.

2.9

Keep watching the condition of load, stop operating lift table if load

becomes unstable.

2.10

Check and maintain the lift table regularly.

2.11

Do not use the lift table continuously, the pump station would be

damaged.

2.12

Stop operating the lift table if the temperature of the oil is too high.

2.13

The table should be lowered to the bottom if the lift table is not used.

3. oPErATINg guIDANCE

3.1 Emergency switch

When you press down this switch, it will switch off the power, and then you turn it

clockwise, it will switch on the power.

3.2 Lifting switch

When you press down this switch, the table will lift; when you loose your hand,

the table will stop lifting.

3.3 Lowering switch

When you press down this switch, the table will be lowering; when you loose

your hand, the table will stop lowering.

3.4

The table can not lift or lower when the function of safety protection frame

starts. When you press down the lifting or lowering switch, the table will lift

or lower again.

Attention:

Environmentally hazardous waste, such as batteries and electronics,

will have a negative effect on the environment, or health, if handled

incorrectly.

The waste packages should be sorted and put into solid dustbins

according to the materials and be collected disposal by local special

environment protection bureau. To avoid pollution, it’s forbidden to

throw away the wastes randomly.

To avoid leaking during the use of the products, the user should

prepare some absorbable materials (scraps of wooden or dry duster

cloth) to absorb the leaking oil in time. To avoid second pollution to

the environment, the used absorbable materials should be handed in

to special departments in terms of local authorities.

Note:

All of the information reported herein is based on data available at the

moment of printing. We reserve the right to modify our own products

at any moment without notice and incurring in any sanction. So, it is

suggested to always verify possible updates.

Summary of Contents for 31088

Page 4: ...3 035 180 500 ajprodukter se 6 ELsystem 6 1 Kretsdiagram ...

Page 18: ...3 45 59 400 999 ajprodukter dk 6 EL SYSTEM 6 1 kredsløbsdiagram ...

Page 32: ...3 67 02 42 00 ajprodukter no 6 ELEKTRISK ANLEGG 6 1 koblingsskjema ...

Page 46: ...3 010 32 888 50 ajtuotteet fi 6 Sähköjärjestelmä 6 1 Kytkentäkaavio ...

Page 60: ...3 6000 270 ajtooted ee 6 Elektrisüsteem 6 1 Elektriskeem ...

Page 74: ...3 67 62 52 72 ajprodukti lv 6 ELEKTROSISTĒMA 6 1 Elektriskā shēma ...

Page 88: ...3 8 5 2 785 980 ajproduktai lt 6 ELECTRICAL SYSTEM 6 1 Circuit diagram ...

Page 102: ...3 283 933 763 ajprodukty cz 6 ELEKTRICKÝ SYSTÉM 6 1 Obvodový diagram ...

Page 116: ...3 02 48 214 712 ajprodukty sk 6 ELEKTRICKÝ SYSTÉM 6 1 Obvodový diagram ...

Page 144: ...3 22 862 38 76 ajprodukty pl 6 UKŁAD ELEKTRYCZNY 6 1 Schemat obwodu ...

Page 158: ...3 01252 359760 ajproducts co uk 6 ELECTRICAL SYSTEM 6 1 Circuit diagram ...

Page 172: ...3 01 2811700 ajproducts ie 6 ELECTRICAL SYSTEM 6 1 Circuit diagram ...