2

|

01-2811700 • ajproducts.ie

Thank you for choosing our product. Before using this product,

please read this manual carefully, understand the construction

and performance, and operate, maintain according to the

manual. Overload is especially forbidden to avoid injuring

person, damage of load and truck. Any damage or injuring

which is caused by change of truck without the permission is

nothing to do with the manufacturer.

1. Preface

The Rough Terrain Truck is suitable for using at construction site, factories,

buildings and roads, transports various materials.

1) Because of the two Ø568mm front wheels and two Ø250mm steering

wheels, the truck is suitable for any condition of the road. And the front

wheels are pneumatic, it can reduce the friction force, minish the vibration.

You can operate it easily and steadily.

2) Because the steering wheels are wider and solid, it enhances the carrying

capacity, reduces the deformation. It is flexible to change direction lightly

and handily, which improves the adaptability in ground, makes the truck

be steadier, and increases carrying security.

3) Because of the double action pump, the work efficiency has been

improved greatly.

4) Because of the higher lifting height, it extends the distance of the truck to

the ground to suit for uneven and complicated ground.

5) Because of the adjustable fork, it can be suitable for material of different

shapes. It makes the transportation more convenient and reliable.

2. SPecification

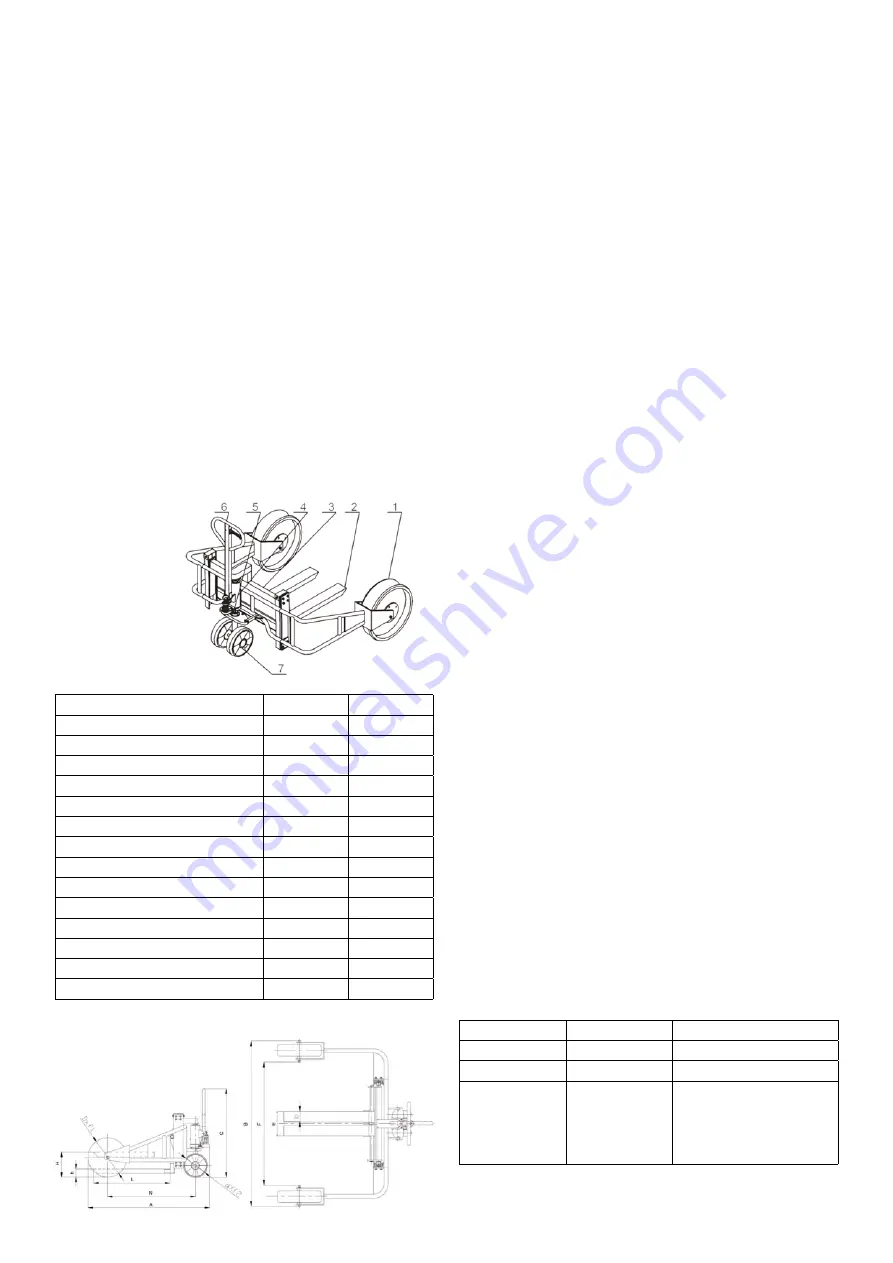

figure 1: constructions of the truck.

1. Front wheel

2. Fork

3. Chassis

4. Cylinder

5. Release valve

6. Steering handle

7. Steering wheel

Form 1: Specification

Model

rP1000

rP1500

Capacity Kg

1000

1500

Max. Lifting Height (H) mm

240

240

Min. Height of Fork (h) mm

70

70

Wheel Base (N) mm

973

973

Width of the forks (E) mm

216-680

216-680

Length of the fork (L) mm

800(860)

800(860)

Dia. of Front Wheel (d×f1) mm

Ø568x145

Ø568x145

Dia. of Steering Wheel (d×f2) mm

Ø250x50

Ø250x50

Min. Turning Radius (R) mm

1400

1400

Distance between two wheels (F) mm

1230

1230

Overall Length (A) mm

1407

1407

Overall Width (B) mm

1670

1670

Overall Height (C) mm

1280

1280

Net Weight Kg

218

238

figure 2: Dimensions of the truck

3. StePS of inStallation

1. Take out the sliding welding frame (F5400), left and right piece of welding

frame of front wheel (F5410), put F5410 on two sides of F5400, take

hexagram screw bolt M12 (F5413) through into washer 12 (F5411)

and spring washer 12 (F5412). Fasten F5400 and (F5410)

2. Take out front wheel Ø568 (F5422), bush (F5418), shaft of front wheel

(F5417) , Mount the front wheel to the wheel frame with Shaft and bush,

then put washer 20 (F5416), spring washer 20 (F5415) on the both ends of

the shaft , fasten two ends with self-locking nut M20 (F5414).

3. Take out cylinder assy.(5400), insert the shaft (5404) into the rear

wheel(5405)put rear wheel (5404) put retaining ring (128) onto the shaft

(5404), then press the anti-dust cover. Put steel-ball (101) onto the

piston of the jack, take out the welding base and put into jack, use

the pin (3926) to fasten the rhombic plate to the barcket, then press

the elastic pin. Screw on the hexagram bolt M6 (F3101) to the base.

4. Take out handle (H3101) into cylinder housing, pull out the pin (3111), put

the pin(3111) into one side of the cylinder housing, connect the

cylinder housing and handle. Pay attention to the position of the hole

on the pin, make sure that the wire of the chain go through the hole of the

pin. Use spring pin (H3103) to fix the shaft, press plunger down and take

out the pin. Raise the connecting rod and put the pin of chain into the

concave.

5. Swivel down the handle to pump the piston to the top position, Insert the

long axle(F5407) into the hole of the base housing and the fork assy.

(F5409), then fix with two retaining rings on both sides, put the cover on it,

then fixed with M10 bolt (F5426), washer (F5427) and elastic washer(F5428).

4. oPerating inStructionS

1. Make sure the truck is assembled correctly before operating it.

2. The lifting and lowering is controlled by the control valve. When the valve

is at the free position or the handle is turned anti-clockwise, you can

lift the fork by pressing the handle up and down. When you turn the valve

handle clockwise, the fork descends. Contrarily, when you turn the valve

handle anti-clockwise or release the valve, the fork stops lowering.

3. The product is equipped with a double action pump. When the handle

is pressed up and down, the piston raises continually. It improves the work

efficiency. It is better to operate the truck by two persons to reduce the

work intensity. If you operate the truck by one person, you could move the

handle to one side to reduce the operating force.

4. When the truck is loaded: Please put the gravity center of the load as

close to the root of the fork as possible. Avoid the unbalanced load. Adjust

the fork width to proper dimension. To make sure every part is pressed

equably, lift and lower smoothly, move reliably.

5. When the truck is loaded, pay more attention to the pressure of tyre.

Whether the pressure is too high or too low, it is harmful for the lifetime of

the wheel.

5. Safety guiDe

1) When operating the truck must be careful, especially at the corner and the

slope.

2) Do not put the load on the fork for a long time. When operation is finished,

you should lower the fork to the lowest position.

3) Do not lift person.

4) The working temperature is -20°C~+40°C. If you want to operate the truck

in cold area, must use low-temperature-hydraulic-oil.

5) When it is not used, make sure put it into the garage instead of outdoor.

6. Maintenance

1) Maintenance regular and replace the easy-worn parts in time can prolong

the lifetime of truck.

2) The truck must be maintained by the professional person.

3) If you want to change parts, please use the parts supplied by

manufacturer. Otherwise, it will be harmful for the truck.

4) If the truck needs maintenance, please disassemble the truck as the

diagram in this manual.

5) Refer to the parts list in the manual, change the broken parts when

maintaining.

6) Daily clean and periodic lubrication is necessary and it will prolong the

lifetime of the truck.

item

Period

Program

Movable Parts

4 weeks

Add the normal lubricating oil

Hydraulic Parts

1 year

Do as “change oil”

Wheels

4 weeks

Check the abrasion. If it is more

than 1mm, please change the

wheel. When the wheel pressure

less than 200Kpa, please inflate

the tyre. The recommended

pressure is 250Kpa.

Change Oil

Oil: L-HV46

Volume: 0.3L