AKO-5761x

Gas detector

Quick guide

5761H012 Ed.01

AKO ELECTROMECÁNICA , S.A.L.

Avda. Roquetes, 30-38

08812

•

Sant Pere de Ribes.

Barcelona

•

Spain.

Tel.: +34 902 333 145

Fax: +34 938 934 054

www.ako.com

GB

Warnings

-Detectors should be installed in a place protected from vibrations, water and corrosive gases, where the ambient temperature does not exceed the value indicated in the technical data.

-Detectors are not suitable for areas classified as potentially explosive.

-Detectors supervise a point and not an area. If the gas leak does not reach the sensor, or the level of concentration in that point does not reach the foreseen values according to

the type of gas no alarm will be activated. If perimeter supervision is required, several sensors should be installed around that area.

Working conditions:

-Avoid handling refrigerant gases near the sensor. If this is unavoidable, use Set Hold or Maintenance mode.

-Keep the detector work environment free of chemical agents (solvents, acetone vapours, paints, alcohol, cleaning products, silicone and derivatives, ethylene, etc.).

-Avoid installing the detector near products or devices that might give off CO . (

AKO-57615

only)

2

-Human breathing near the detector may increase the level of CO . and generate false alarms. (

AKO-57615

only)

2

-Do not paint the detector or place it near solvents or paints. (

AKO-57613/4

only)

-The sensor should be installed away from: -

Areas where fermentation and ripening processes of products (bread, pizza, fruit, etc.) may occur. (

AKO-57613/4

only)

-Smoke outlets located in confined spaces or from engines, generators or motorised machinery (fork-lift trucks, etc.).

-Particularly damp areas or with strong ventilation.

-The detector should usually be installed in an area where gas may concentrate, near to places where gas leaks could start.

-The detector’s location will depend on the refrigerant and will be in areas where gas leaks could concentrate. Taking into account individuals’ safety and their use of space, the lowest position of this space

will be considered for refrigerants heavier than air (HCFC, HFC and CO ) and the highest possible position will be considered for refrigerants lighter than air (NH ).

2

3

3

5

5

7

6

1

0

1

2 R

ev 0

0 2

0

1

7

B

A

A

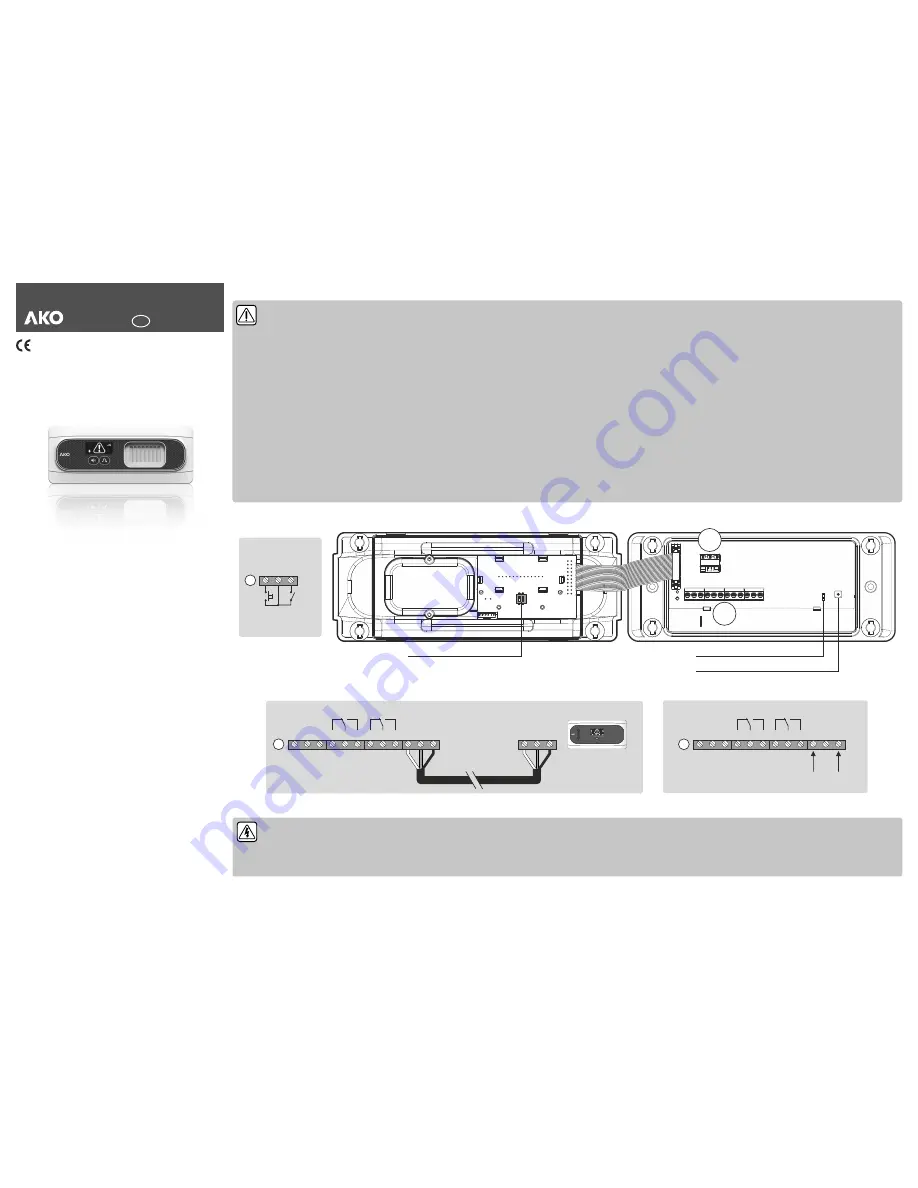

Gnd

DI1

DI2

DIG. IN

Remote

Set Hold

“AUTO-CONFIGURATION” push-button

Remote

Mute

B

C

C

NC

NC

NO

NO

Gas

Pre-Alarm

Gas

Alarm

Tr

-

Tr+

Gnd

RS485 Pre-Alarm

Alarm

Alarm station

Connection to alarm station

15V

15V

S

In

Gnd

Gnd

Input x

B

C

C

NC

NC

NO

Gas

Pre-Alarm

Gas

Alarm

Tr

-

Tr+

Gnd

RS485 Pre-Alarm

Alarm

Independent operation

NO

15V

S

12 - 30 Vdc

Gnd

Always disconnect the power supply to do the wiring.

The wiring between the detector/transmitter and the station should

NEVER

be installed in a conduit together with power, control or supply cables.

Cables for wiring the relay contact should have an adequate section depending on the unit to be connected.

Certain international standards maintain that the power supply of the alarm should originate from a different circuit to that used by the refrigeration and ventilation system.

Please ensure that you comply with

current local regulations.

GAS

Wiring

Pre-alarm jumper

Delay switch

We reserve the right to supply materials that might vary slightly to those described in

our Technical Sheets. Updated information is available on our website.