07/2015

Temperature Difference Controller TDC 3

Page 16 of 47

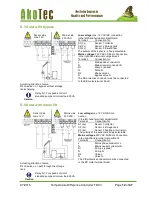

D.11 Solar with follow-on storage tank/Solar & transfer“

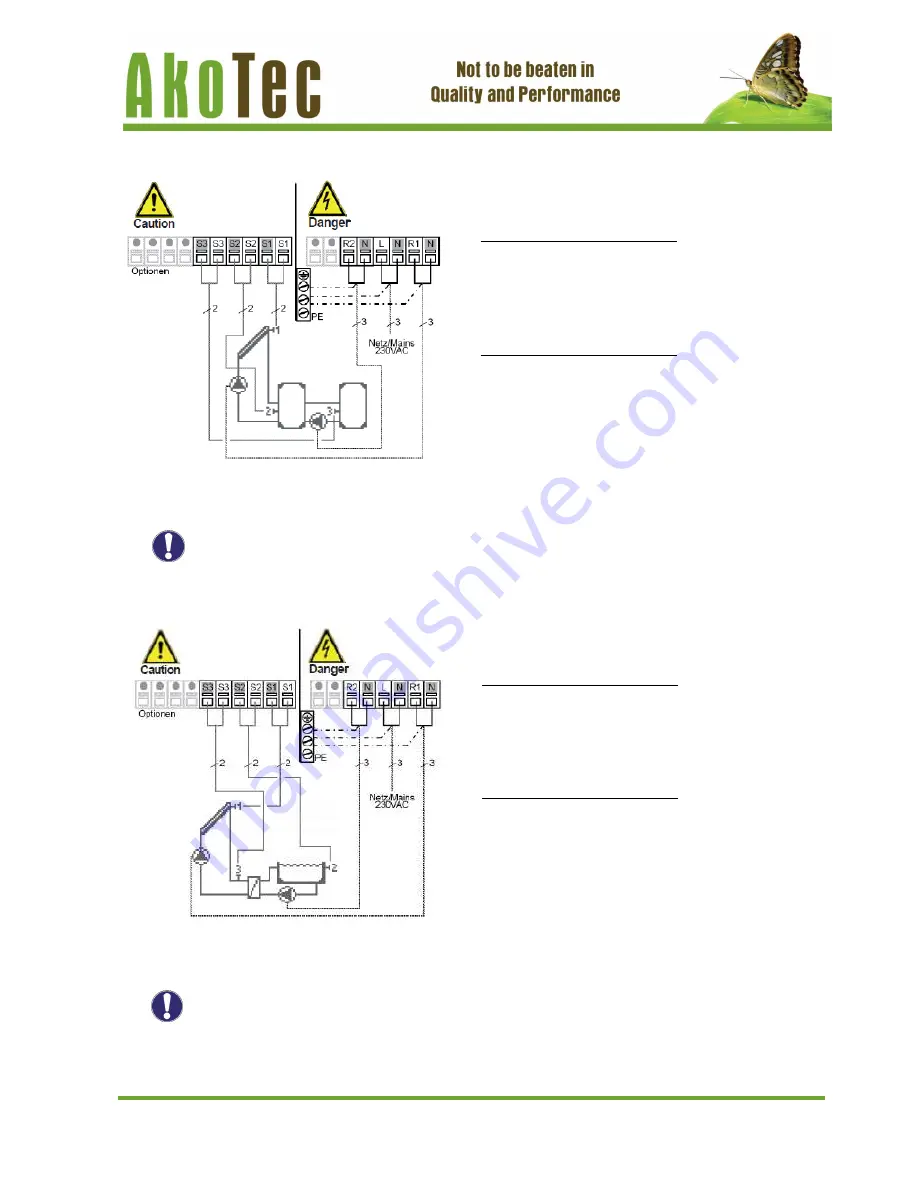

D.12 Solar with swimming pool and heat exchanger

Sensor side

max. 12 V

Mains side

230 VAC

Relay R1: For speed control of

standard pumps, minimum load 20 VA

Caution

Low voltage max. 12VAC/DC connection

in the left-hand terminal compartment!

Terminal:

Connection for:

S1 (2x)

Sensor 1 collector

S2 (2x)

Sensor 2 storage tank 1

S3 (2x)

Sensor 3 storage tank 2

The polarity of the sensors is freely selectable.

Mains voltages 230VAC 50-60Hz Connection

in the right-hand terminal compartment!

Terminal:

Connection for:

L

Mains phase conductor L

N

Mains neutral conductor N

R1

Pump L (speed)

N

Pump N

R2

Pump (storage tank 2) L

N

Pump (storage tank 2) N

The PE protective conductor must be connected

to the PE metal terminal block!

Sensor side

max. 12 V

Mains side

230 VAC

Relay R1: For speed control of

standard pumps, minimum load 20 VA

Low voltage max. 12 VAC/DC connection

in the left-hand terminal compartment!

Terminal:

Connection for:

S1 (2x)

Sensor 1 collector

S2 (2x)

Sensor 2 swimming pool

S3 (2x)

Sensor 3 forward fl ow

The polarity of the sensors is freely selectable.

Mains voltages 230 VAC 50-60 Hz Connection

in the right-hand terminal compartment!

Terminal:

Connection for:

L

Mains phase conductor L

N

Mains neutral conductor N

R1

Pump, prim. L (speed)

N

Pump, primary N

R2

Pump, secondary L

N

Pump, secondary N

The PE protective conductor must be connected

to the PE metal terminal block!

Caution