Operation and Configuration

akYtec GmbH · Vahrenwalder Str. 269 A · 30179 Hannover · Germany Tel.: +49 (0) 511 16 59 672-0 · www.akytec.de

24

–

in case of the analog control Output 1 will be set to the level specified in the parame-

ter

mvEr

(PID safe state)

In the Network control mode the output signal will be set to the last saved output level.

Set

r-S

= StoP to deactivate the alarm. Set

r-S

= rUn to resume control. The detailed

descriptions of errors and remedy actions are given in Table D.1.

6.15 Stop state

When control is stopped, the control output will be set to the level specified in the

param-

eter:

–

onST

– Output 1 state when on-off control is OFF

–

mdST

– Output 1 state when PID control is OFF

If

mdST

= o, the output signal will be set to the last saved output level

If

mdST

= mvST, the output signal will be set to the level specified in the parameter

mvST

(PID stop level).

6.16 RS485 network settings

To establish communication via RS485 connect the RS485 lines to terminals D+ and D-

(see 5.1) and set the following network parameters in the menu group

Comm

(see Table

C.1):

Prot

– Protocol (akYtec, Modbus RTU, Modbus ASCII)

bPS

– Baud rate (2.4…115.2 kbit/s)

A.LEn

– Address bits (7, 8)

Addr

– Network address. Valid values:

0…255 for

Prot

=

OWEN

and

A.LEn

= 8

0…2047 for

Prot

=

OWEN

and

A.LEn

= 11

0…247 for

Prot

=

MRTU

or

MASC

rSdL

– Response delay (1…45 ms)

Note:

The changed network parameter values come into effect only after restarting the

device (power off and on again or via Network).

The following invariable network parameters are not available in the system menu (see

Table 6.5).

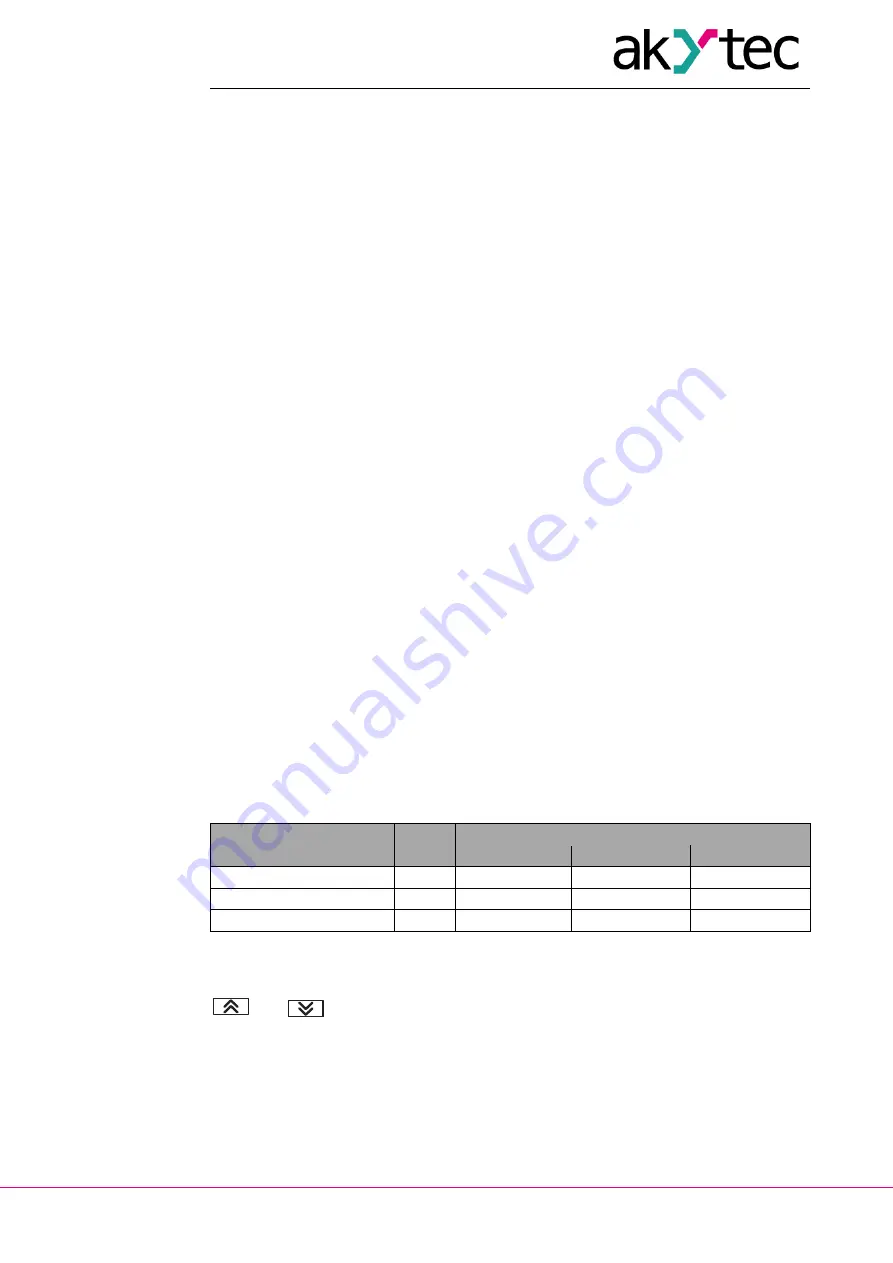

Table 6.5 Invariable network parameters

Parameter

Name

Protocol

akYtec

Modbus RTU

Modbus ASCII

Stop bits

Sbit

1

2

2

Data bits

LEn

8 bit

8 bit

7 bit

Parity

PrtY

none

none

none

6.17 Factory settings

To reset the device to the default settings switch it off

at least for 1 minute,

hold the

and

keys together and then switch the device on. When

[– – – –]

appears

on the upper display, release the keys. The settings will be reset to default values.

6.18 Calibration

The device should be calibrated to restore the accuracy after a long-term operation or

repair works with an effect on the measurement system. Calibration has to be carried out

by the manufacturer.

Contact the Technical Support of akYtec GmbH for further details.