8/00 7 33072C

i30SE Direct Vent Gas-Fired Fireplace Insert (Firebox Only)

A Division of Hearth Technologies Inc.

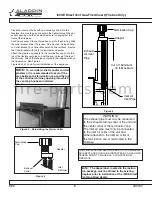

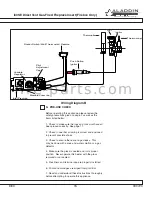

V. STEP-BY-STEP INSTALLATION

A. CONNECTING THE VENT PIPE.

The damper of

the masonry or factory-built chimney may have to be

removed to allow installation of the flexible-vent pipe.

Before installing the 3” flex vent pipe, mark or label

the exhaust pipe at both ends.

Install the 3-inch flexible vent pipes down through the

chimney. Remove the starting collar bracket from the

top of the unit. See Figure 3. Attach and secure

the bottom ends of the flex pipes to the starting collar

bracket with 3 sheet metal screws on each collar.

Attach the labeled pipe to the exhaust collar on the

starter collar bracket.

Note:

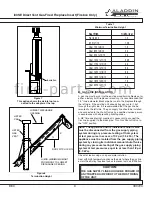

Fireplace chimney systems must

be cleaned thoroughly and inspected

before installation of the appliance. If

any portion of the chimney system shows

signs of structural or mechanical weak-

nesses, such as cracks, leaky joints, cor-

roded or warped surfaces, the faulty por-

tion must be repaired or replaced.

INSTALLATION AND REPAIR SHOULD BE DONE BY A QUALIFIED SERVICE PERSON. THE

HEATER SHOULD BE INSPECTED BEFORE USE AND AT LEAST ANNUALLY BY A QUALIFIED

SERVICE PERSON. MORE FREQUENT CLEANING MAY BE REQUIRED DUE TO EXCESSIVE

LINT FROM CARPETING, BEDDING MATERIAL, ETC. IT IS IMPERATIVE THAT CONTROL

COMPARTMENTS, BURNERS AND CIRCULATING AIR PASSAGEWAYS OF THE HEATER BE

KEPT CLEAN.

Tools and building supplies normally

required for installation.

Tools

Pliers

Phillips screwdriver

Tape measure

Level

Electrical drill and bits

Square

High Temperature Sealant Material

High Temperature Sealant Material.

Sealants

that will withstand high temperatures (at least

350 degrees Fahrenheit); General Electric RTV103

(Black), or equivalent. Rutland, Inc. Fireplace Mortar

#63, or equivalent; Dow Corning 732 or equivalent.

Figure 3

Removing the Starter Collar

WARNING!

1.

Wear gloves and safety glasses for protection.

2.

Keep hand tools in good condition. Sharpen cutting edges and make sure tool

handles are secure.

3.

Always maintain the minimum air space required to the enclosure to prevent fire.

4.

Read the following installation instructions.

f i r e - p a r t s . c o m