Safety Section 1-13

SAFETY

HYDRO 88 & 96 03/94

© 2003

Alamo Group Inc.

SAFETY

I

n addition to the design and configuration of this Implement, including Safety Signs and Safety Equipment,

hazard control and accident prevention are dependent upon the awareness, concern, prudence, and proper

training of personnel involved in the operation, transport, maintenance, and storage of the machine. Refer also

to Safety Messages and operation instruction in each of the appropriate sections of the Tractor and Equipment

Manuals. Pay close attention to the Safety Signs affixed to the Tractor and Equipment.

(SG-18)

PARTS INFORMATION

Alamo Industrial mowers use balanced and matched system components for blade carriers, blades,

cuttershafts, knives, knife hangers, rollers, drivetrain components, and bearings. These parts are made and

tested to Alamo Industrial specifications. Non-genuine "will fit" parts do not consistently meet these

specifications. The use of “will fit” parts may reduce mower performance, void mower warranties, and

present a safety hazard. Use genuine Alamo Industrial mower parts for economy and safety.

(SPAM-1)

SEE YOUR ALAMO DEALER

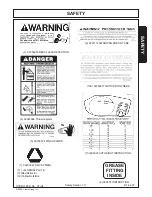

WARNING!

Never operate the Tractor and Mower if the Implement input driveline is

directly connected to the Tractor transmission. Tractor braking distances

can be substantially increased by the momentum of the rotating Mower

blades driving the Tractor transmission even though the Tractor clutch has

been disengaged. Install an over running clutch between the Tractor PTO

and the Mower driveline to prevent this potentially dangerous situation.

(S3PT-16)

WARNING!

When attaching the Implement input driveline to the Tractor PTO, it is

important that the connecting yoke spring activated locking collar slides

freely and the locking balls are seated securely in the groove on the Tractor

PTO shaft. A driveline not attached correctly to the Tractor PTO shaft

could come loose and result in personal injury and damage to the

Implement.

(S3PT-17)

WARNING!

Before operating the Mower, check to make sure the Implement input

driveline will not bottom out or become disengaged. Bottoming out occurs

when the inner shaft penetrates the outer housing until the assembly

becomes solid-it can shorten no more. Bottoming out can cause serious

damage to the Tractor PTO by pushing the PTO into the Tractor and

through the support bearings or downward onto the PTO shaft, breaking

it off. A broken drive line can cause personal injury.

(S3PT-18)

DANGER!

Never crawl under a raised Implement supported solely by the Tractor 3-

Point hitch. Release of the control lever or mechanical failure will result

in the Implement falling and possible injury or death. Always securely

block up the Implement before crawling underneath to perform repairs and

service.

(S3PT-19)

Summary of Contents for HYDRO 88

Page 2: ......

Page 4: ......

Page 10: ......

Page 11: ...Safety Section 1 1 HYDRO 88 96 04 02 2003 Alamo Group Inc SAFETY SECTION ...

Page 31: ...Introduction Section 2 1 HYDRO 88 96 03 94 2003 Alamo Group Inc INTRODUCTION SECTION ...

Page 35: ...Assembly Section 3 1 HYDRO 88 96 03 94 2003 Alamo Group Inc ASSEMBLY SECTION ...

Page 38: ......

Page 39: ...OPERATION SECTION Operation Section 4 1 2002 Alamo Group Inc ...

Page 72: ......

Page 73: ...Operation Section 4 1 HYDRO 88 96 03 94 2003 Alamo Group Inc MAINTENANCE SECTION ...

Page 88: ......

Page 89: ...HYDRO 88 96 03 94 2003 Alamo Group Inc PARTS SECTION ...

Page 92: ...GENERAL ASY HYDRO 88 96 08 04 2004 Alamo Group Inc Parts Section 4 ...

Page 96: ...SPEED INCREASER P N 02897900 OLD STYLE HYDRO 88 96 08 04 2004 Alamo Group Inc Parts Section 8 ...

Page 106: ...MOWER ASY 88 HYDRO 88 96 08 04 2004 Alamo Group Inc Parts Section 18 ...

Page 108: ...MOWER ASY 88 HYDRO 88 96 08 04 2004 Alamo Group Inc Parts Section 20 ...

Page 110: ...MOWER ASY 96 HYDRO 88 96 08 04 2004 Alamo Group Inc Parts Section 22 ...

Page 112: ...MOWER ASY 96 HYDRO 88 96 08 04 2004 Alamo Group Inc Parts Section 24 ...

Page 116: ...HYDRO 88 96 OMWPL 08 04 Printed U S A P N 803342 ...