Summary of Contents for BUSH HOG PVB

Page 5: ...Safety Section 1 1 SAFETY SECTION...

Page 16: ...SAFETY PVB PVS 08 20 Safety Section 1 12 SAFETY 2020 Alamo Group Inc Decal Description...

Page 18: ......

Page 19: ...Introduction Section 2 1 INTRODUCTION SECTION...

Page 23: ...Assembly Section 3 1 ASSEMBLY SECTION...

Page 25: ...Operation Section 4 1 OPERATION SECTION...

Page 46: ......

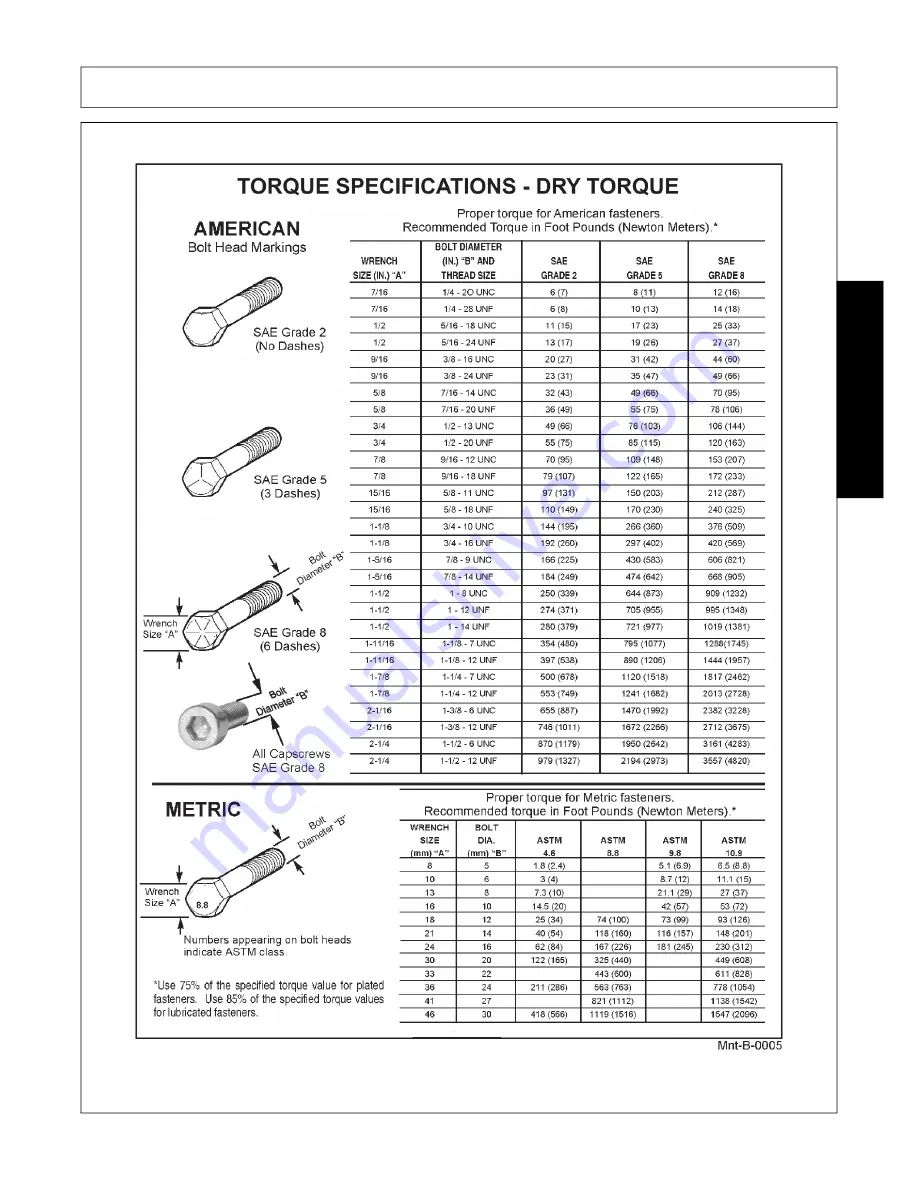

Page 47: ...Maintenance Section 5 1 MAINTENANCE SECTION...

Page 49: ...MAINTENANCE PVB PVS 08 20 Maintenance Section 5 3 MAINTENANCE 2020 Alamo Group Inc...

Page 51: ...MAINTENANCE PVB PVS 08 20 Maintenance Section 5 5 MAINTENANCE 2020 Alamo Group Inc...

Page 52: ......

Page 54: ...PVB PVS PULVERIZER 08 20 P N 95161 Printed U S A PVB PVS PULVERIZER...