MAINTENANCE

FX17/FX21 04/13

Maintenance Section 5-7

© 2013 Alamo Group Inc.

MAINTENANCE

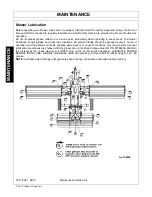

7. Reinstall grease fitting to housing. Grease Fitting must have locking pin installed which inserts into grease

hole in bearing when installed. If Grease Fitting does not have a pin, order a new grease fitting. Grease

fitting must be tight and seated in grease hole in bearing to prevent bearing from rotating in housing.

8. Attach roller bearing and housing assembly to bracket with seal between housing and bracket.

9. Slide bearing and bracket assemblies on each end of roller.

10. Check bearing for proper installation in housing by gently rocking bearing and bracket assembly in end of

roller. Play should be slight to none at all.

11. Install roller and bearing and bracket assemblies on mower.

12. Lubricate roller bearing until lubricant can be seen coming out between roller and bearing housing.

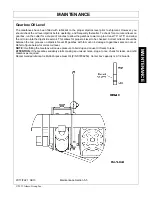

CUTTERSHAFT BEARING REPLACEMENT

OUTBOARD (DRIVE) BEARING

For Rear Head Non Driveside Bearing and Wing Inboard Bearing Replacement:

1. Lift cutter unit to maximum horizontal height;

then, securely support ends of cutterhousing.

2. Remove enough knives to place a floor jack

under center of cuttershaft.

3. Securely support cuttershaft.

NOTE

: The cuttershaft must remain supported

while changing bearings.

4. Remove outboard fender-outboard bearings or

wing drivelines-wing inboard bearings. Loosen

setscrews securing bearing inner race to

cuttershaft. Use special 3/16 hex allen wrench

which has been shortened to reach into

bearings.

5. Remove fasteners securing bearing and

housing assembly to cutterhousing; then

remove bearing and housing assembly.

NOTE:

There are two tapped holes in the housing

which can be used to pull bearing and housing

assembly out by using special tool No. 701627.

6. Using a jack to hold up cuttershaft in proper

alignment, install bearing and housing

assembly to cutter unit and make certain that

bearing setscrew is located in keyway on

cuttershaft. Grease bearing and install cap over

fitting.

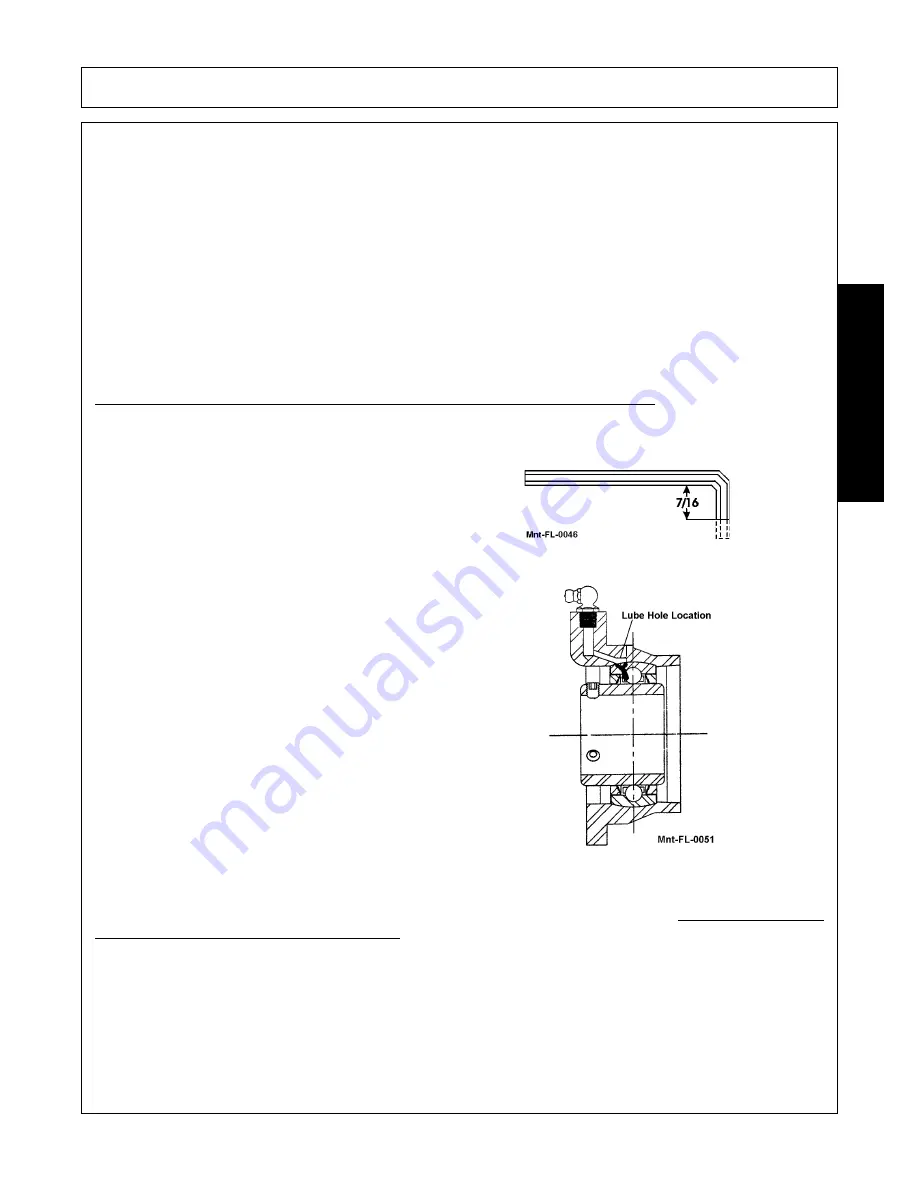

NOTE:

Make sure grease is getting into bearing.

7. Replace outboard fender or wing driveline. Make sure to time wing drivelines properly before reconnecting.

NOTE:

Grease Lube Hole in bearing outer race must align with lube hole in housing. Inboard or Drive Side

Bearing cannot be used as Outboard Bearing.

Summary of Contents for RHINO FLEX FLAIL FX17

Page 2: ......

Page 9: ...Safety Section 1 1 2013 Alamo Group Inc SAFETY SECTION ...

Page 25: ...SAFETY FX17 FX21 04 13 Safety Section 1 17 2013 Alamo Group Inc SAFETY Decal Description ...

Page 26: ...SAFETY FX17 FX21 04 13 Safety Section 1 18 2013 Alamo Group Inc SAFETY ...

Page 27: ...SAFETY FX17 FX21 04 13 Safety Section 1 19 2013 Alamo Group Inc SAFETY ...

Page 28: ...SAFETY FX17 FX21 04 13 Safety Section 1 20 2013 Alamo Group Inc SAFETY ...

Page 29: ...SAFETY FX17 FX21 04 13 Safety Section 1 21 2013 Alamo Group Inc SAFETY ...

Page 30: ...SAFETY FX17 FX21 04 13 Safety Section 1 22 2013 Alamo Group Inc SAFETY ...

Page 31: ...SAFETY FX17 FX21 04 13 Safety Section 1 23 2013 Alamo Group Inc SAFETY ...

Page 32: ...SAFETY FX17 FX21 04 13 Safety Section 1 24 2013 Alamo Group Inc SAFETY ...

Page 33: ...SAFETY FX17 FX21 04 13 Safety Section 1 25 2013 Alamo Group Inc SAFETY ...

Page 34: ...SAFETY FX17 FX21 04 13 Safety Section 1 26 2013 Alamo Group Inc SAFETY ...

Page 36: ......

Page 37: ......

Page 63: ......

Page 89: ...Introduction Section 2 1 2012 Alamo Group Inc INTRODUCTION SECTION ...

Page 94: ......

Page 95: ...Assembly Section 3 1 2013 Alamo Group Inc ASSEMBLY SECTION ...

Page 101: ...Operation Section 4 1 2013 Alamo Group Inc OPERATION SECTION ...

Page 143: ...Maintenance Section 5 1 2013 Alamo Group Inc MAINTENANCE SECTION ...

Page 155: ......

Page 156: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 29 2013 Alamo Group Inc SEGURIDAD ...

Page 157: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 28 2013 Alamo Group Inc SEGURIDAD ...

Page 158: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 27 2013 Alamo Group Inc SEGURIDAD ...

Page 159: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 26 2013 Alamo Group Inc SEGURIDAD ...

Page 160: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 25 2013 Alamo Group Inc SEGURIDAD ...

Page 161: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 24 2013 Alamo Group Inc SEGURIDAD ...

Page 162: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 23 2013 Alamo Group Inc SEGURIDAD ...

Page 163: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 22 2013 Alamo Group Inc SEGURIDAD ...

Page 164: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 21 2013 Alamo Group Inc SEGURIDAD ...

Page 165: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 20 2013 Alamo Group Inc SEGURIDAD ...

Page 166: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 19 2013 Alamo Group Inc SEGURIDAD ...

Page 167: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 18 2013 Alamo Group Inc SEGURIDAD ...

Page 168: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 17 2013 Alamo Group Inc SEGURIDAD ...

Page 169: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 16 2013 Alamo Group Inc SEGURIDAD ...

Page 184: ...Sección de Seguridad 1 1 2013 Alamo Group Inc SECCIÓN DE SEGURIDAD ...

Page 185: ......