9

Prepare For Safe Operation

Check The Mower And Tractor Equipment

Before beginning your work day inspect the machine

and have all systems in good operational condition.

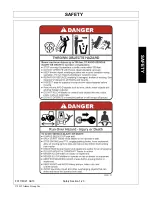

WARNING!

Prevent possible crushing injury from falling

equipment. Hydraulic system or part failure could cause

unsupported equipment to fall.

Do not go under raised

equipment unless it is properly supported according

to the operator’s manual.

— Perform daily and periodic service procedures as

instructed by the equipment manufacturer.

— Check for loose, broken, missing or damaged tractor

and mower parts. Repair or replace these parts.

— Check for proper tractor and mower attachments.

— Check for proper tractor and mower PTO rpm rating

match.

— Check mower blade(s) condition. Replace severely

worn, bent, gouged or nicked blades including the

blade bolts and fasteners. Never straighten or weld

on blades.

— Ensure thrown object shielding is properly installed

and in good condition. Repair or replace if damaged

or missing.

Read Manual –

Block Up or

Securely Support

Mower

Maintain

Machine

Walk-Around

Inspection

Prepare For Safe Operation

— Check that all guards and shields are in place and

that all equipment is in good operating condition. This

includes PTO driveline, gearbox and implement guards

and shields that are used for operator protection.

— Check for properly latched driveline yoke-end locking

devices.

— Check for damaged or leaky tractor and mower

hydraulic systems. Repair or adjust as needed.

WARNING!

Hydraulic fl uid under pressure can penetrate

the skin or eyes and cause serious injury, blindness or

death. Fluid leaks under pressure may not be visible.

Use a piece of cardboard or wood to fi nd leaks, not

your hand. Wear eye protection.

If fl uid is injected

into the skin, it must be removed within a few hours by

medical personnel familiar with this type of injury.

— Keep the operator platform surface clean and free of

grease, oil, dirt, snow or ice. Steps and handholds

must be clean and functional.

— Ensure work lights are kept clean (if equipped). Check

that all lights work properly.

— Ensure the slow moving vehicle (SMV) sign, refl ectors

and warning lights are in good condition and can be

clearly seen.

— Ensure all tools or loose objects are removed or

securely fastened while operating the machine.

— Check all safety signs for clarity. Replace damaged

signs.

Check for

Leaks and Inspect

Hoses

Check for Missing/

Damaged Guards

and Shields

Put Away

Tools

Summary of Contents for RHINO FLEX FLAIL FX17

Page 2: ......

Page 9: ...Safety Section 1 1 2013 Alamo Group Inc SAFETY SECTION ...

Page 25: ...SAFETY FX17 FX21 04 13 Safety Section 1 17 2013 Alamo Group Inc SAFETY Decal Description ...

Page 26: ...SAFETY FX17 FX21 04 13 Safety Section 1 18 2013 Alamo Group Inc SAFETY ...

Page 27: ...SAFETY FX17 FX21 04 13 Safety Section 1 19 2013 Alamo Group Inc SAFETY ...

Page 28: ...SAFETY FX17 FX21 04 13 Safety Section 1 20 2013 Alamo Group Inc SAFETY ...

Page 29: ...SAFETY FX17 FX21 04 13 Safety Section 1 21 2013 Alamo Group Inc SAFETY ...

Page 30: ...SAFETY FX17 FX21 04 13 Safety Section 1 22 2013 Alamo Group Inc SAFETY ...

Page 31: ...SAFETY FX17 FX21 04 13 Safety Section 1 23 2013 Alamo Group Inc SAFETY ...

Page 32: ...SAFETY FX17 FX21 04 13 Safety Section 1 24 2013 Alamo Group Inc SAFETY ...

Page 33: ...SAFETY FX17 FX21 04 13 Safety Section 1 25 2013 Alamo Group Inc SAFETY ...

Page 34: ...SAFETY FX17 FX21 04 13 Safety Section 1 26 2013 Alamo Group Inc SAFETY ...

Page 36: ......

Page 37: ......

Page 63: ......

Page 89: ...Introduction Section 2 1 2012 Alamo Group Inc INTRODUCTION SECTION ...

Page 94: ......

Page 95: ...Assembly Section 3 1 2013 Alamo Group Inc ASSEMBLY SECTION ...

Page 101: ...Operation Section 4 1 2013 Alamo Group Inc OPERATION SECTION ...

Page 143: ...Maintenance Section 5 1 2013 Alamo Group Inc MAINTENANCE SECTION ...

Page 155: ......

Page 156: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 29 2013 Alamo Group Inc SEGURIDAD ...

Page 157: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 28 2013 Alamo Group Inc SEGURIDAD ...

Page 158: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 27 2013 Alamo Group Inc SEGURIDAD ...

Page 159: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 26 2013 Alamo Group Inc SEGURIDAD ...

Page 160: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 25 2013 Alamo Group Inc SEGURIDAD ...

Page 161: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 24 2013 Alamo Group Inc SEGURIDAD ...

Page 162: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 23 2013 Alamo Group Inc SEGURIDAD ...

Page 163: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 22 2013 Alamo Group Inc SEGURIDAD ...

Page 164: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 21 2013 Alamo Group Inc SEGURIDAD ...

Page 165: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 20 2013 Alamo Group Inc SEGURIDAD ...

Page 166: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 19 2013 Alamo Group Inc SEGURIDAD ...

Page 167: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 18 2013 Alamo Group Inc SEGURIDAD ...

Page 168: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 17 2013 Alamo Group Inc SEGURIDAD ...

Page 169: ...SEGURIDAD FX17 FX21 04 13 Sección de Seguridad 1 16 2013 Alamo Group Inc SEGURIDAD ...

Page 184: ...Sección de Seguridad 1 1 2013 Alamo Group Inc SECCIÓN DE SEGURIDAD ...

Page 185: ......