The ALM Series burners receive the air for combustion via the air suction chamber. After passing

through this air suction chamber, the combustion air enters into the burner and reaches the

combustion head mixing point via a fan operating in the volute shaped casing. The mixing point

consists of the air diffuser and the combustion head. Here, the fuel injected by the nozzle mixes with

air to form an ideal burning mixture. This way, smooth combustion and maximum fuel savings are

obtained.

7

PRINCIPLES OF OPERATION

BURNER

TYPE

CAPACITY

(kg/h)

HEAT OUTPUT

MOTOR

WEIGHT

(kg)

POWER SUPPLY

kW

Kcal/h

Min.

Max.

Min.

Max.

Min.

Max.

Speed(rpm) Power(kW)

ALM 125/2

53,4

125

632,8

1482

544.680 1.275.000

2850

2,2

66

3~380..400V-50Hz

ALM 174/2

60,5

174,7

717

2071

617.100 1.781.940

2850

3

66

3~380..400V-50Hz

Lower calorific value of the fuel: 10.200 kcal\kg

TECHNICAL SPECIFICATIONS

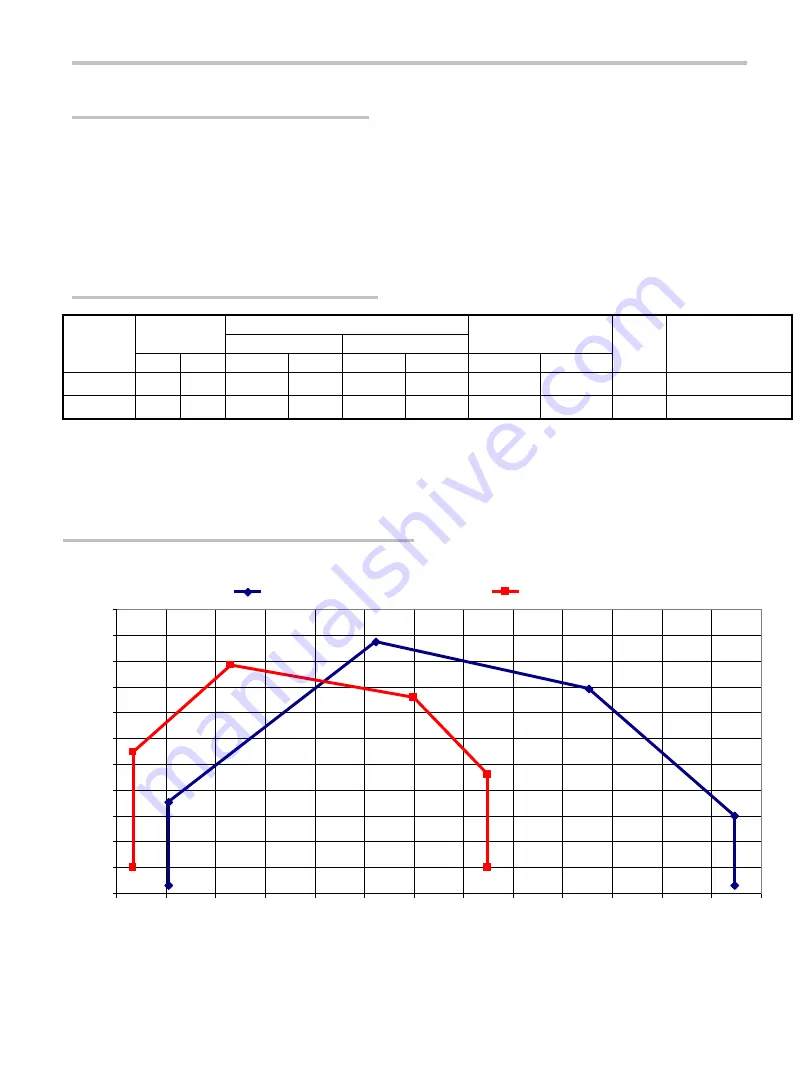

CAPACITY – PRESSURE CURVES

NOTE :

The operation diagram above shows the desired fuel consumption in the combustion chamber as

a function of pressure. The fuel consumption and pressure values represent the values obtained by the

burner to meet the requirements of EN 267.

-1

0

1

2

3

4

5

6

7

8

9

10

50

60

70

80

90

100

110

120

130

140

150

160

170

180

Capacity (kg/h)

C

h

a

m

b

e

r

P

re

s

s

u

re

(

m

b

a

r)

ALM 174/2

ALM 125/2