28

SUITABLE FUELS

CGS2 and CGS3 boilers are only suitable for liquid and gaseous fuels.

Liquid fuels: Light, Medium and Heavy oils (Observe the burner manufacturer's

instructions and local government restrictions).

Gaseous fuels: Natural gas, LPG, Air gas (all gaseous fuels in accordance with

TS 11395 EN 437) (Observe the burner manufacturer's instructions and local

government restrictions).

For all other fuels, contact Alarko Carrier experts.

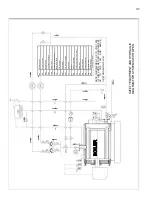

FLUE GAS SYSTEM

CGS2 and CGS3 series boilers are B23 type boilers. The flue gases must be

used with a flue system with sufficient draught so that there is no gas leakage

to the boiler room. Flue calculations must be carried out according to TS EN

11389 EN 13384-1. The inner diameter, height, material and heat insulation of

the flue should be based on the flue gas properties and should not cause

dangerous high and low pressures.

If the system is to be commissioned with liquid fuel, the turbulators in the

smoke ducts must be removed. Turbulators are for use with gaseous fuel.

Since the turbulators are not used, the boiler efficiency will decrease by 2-5%.

There must be a draught between 0 and - 0.3 mbar at the flue gas outlet of the

boiler. For reference, some tables related to this matter are given in the

appendix.

The effective flue height is the difference in height between the boiler flue outlet

and the end point of the flue.

Pre-constraint values for using the flue diagrams in the appendix; The length of

the flue gas ducts between the boiler and the flue should not exceed the % of

the effective flue height. However, it should be noted that it is not longer than

7m, and not less than 0.6m. A maximum of 2 elbows with 90° can be found in

the flue gas ducts (avoid sharp turns).

The inclination of the flue gas ducts should not be downwards. The

recommended elevation angle is 10° upwards.

The weight of the flue gas ducts must not get carried by the boiler's flue gas

connection point and a flanged or leak-tight connection must be used for easy

maintenance.