33

Adjust the burner presets.

Before starting the burner, make sure that all heating system is filled with water,

valve positions, water and fuel side are completely deaerated, and all control

and safety element elements in the heating system are correctly pre-adjusted.

Start the burner, make the capacity and combustion adjustments. In two-stage

and modulating burners, the minimum combustion setting should not be less

than 60% of the boiler capacity.

Check the flue gas values with the analyzer and check that the flue emissions

comply with the applicable restrictions. The values such as SCO, NOx,

sootiness, CO2 or O2, flue gas temperature must be checked.

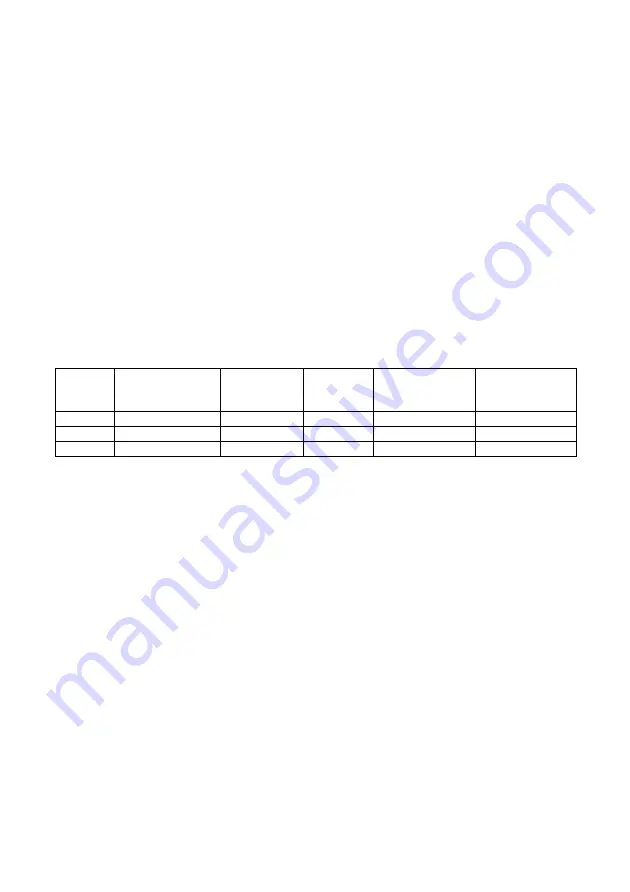

The reference values are given below (applicable standards and regulations

are prioritized, may differ from this table).

Fuel

Sootiness

Degree

(Rinqelmann)

Heat loss %

with waste gas

% C0

2

co

(mg/kWh)

NO

x

(mg/kWh)

Gaseous

(1)

(9)

> 10

<< 100 (1070)

<? 170 (260)

LPG

(1)

(9)

> 10

<<100 (1070)

<< 230 (260)

Diesel

______ (1) ______

___ (11) ____

> 13

<<110 (110)

<< 250 (250)

Note: Flue emission values must be in accordance with applicable regulations.

The values given in parentheses are taken from the "Regulation on Control of

Air Pollution Due to Heating" of Turkish Ministry of Environment and Forestry.

After adjusting the burner, continue to burn the burner and check that the 1st

and, if any, 2nd stage thermostats are working correctly for several times.

Then heat all the water in the heating system up to 85-

90 °C and deaerate the

entire system again. In the first filling process, there is melted air in the cold

water (10-

25 °C) and this air can only be released by heating the system and

disposed out of the system.

Check the setting and function of all control and safety devices again. Record

the system setting parameters.

Call the person(s) who will start the heating system; Please describe all

necessary system information for a correct and safe operation and give

detailed information about the issues that need to be done in a potentially

hazardous situation.