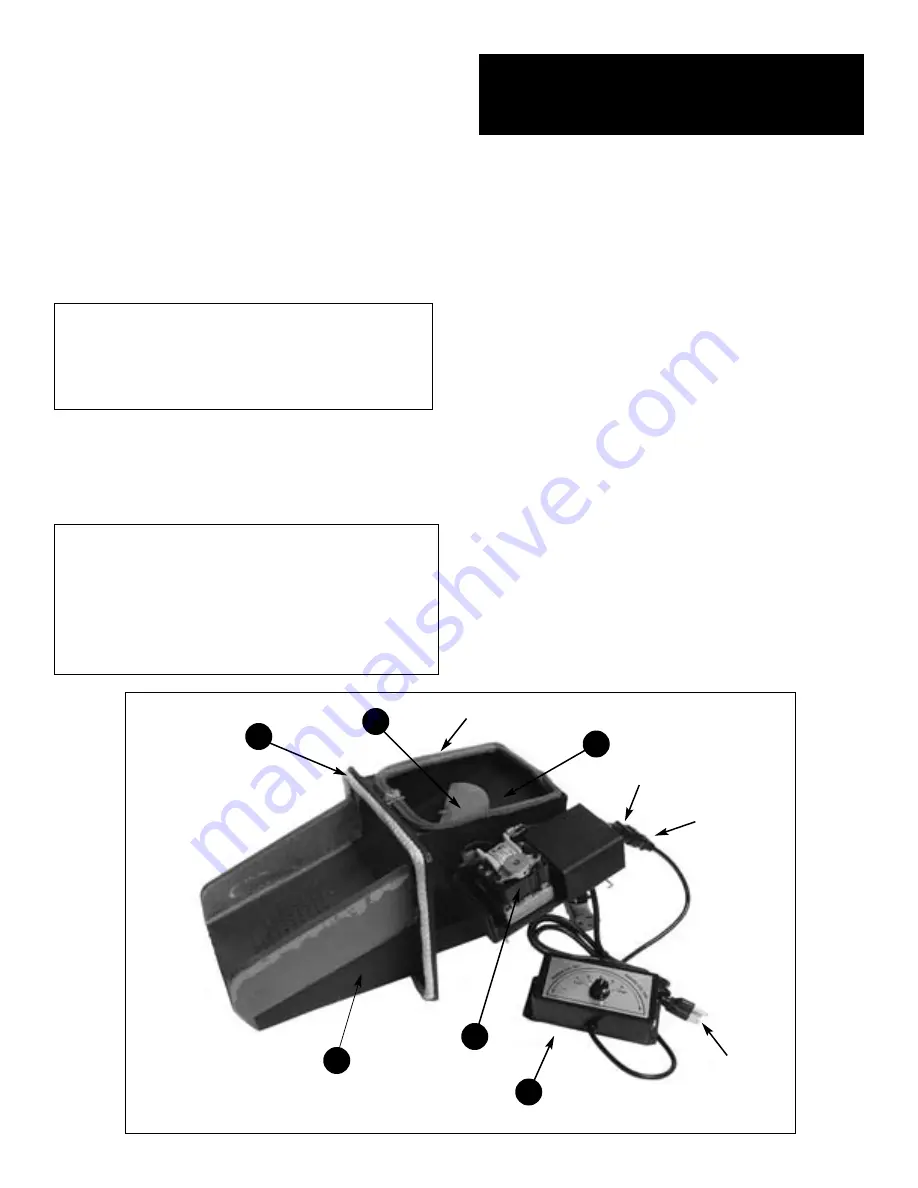

FEEDER ASSEMBLY

Locate unit

(See Fig. 1 on page 3 and Fig. 2 on page 2)

.

Check that strongback gasket is positioned properly as

shown in Fig 1. The strongback gasket position is critical

in that it prevents air escape to the hopper area which

could result in “hopper fire” or warpage to the overplate.

The cast iron grate should sit snug to the housing. The

gear motor moves the

feed bar

in a paddle like fashion,

to push the coal across the grate. A separate motor with a

plastic fan blows air through the grate for the combustion

process. Wiring should be connected as shown below.

NOTE:

Your feeder unit should come to you fully

assembled and ready to plug in.

RHEOSTAT

- is used to control the speed of your air

distribution fan and allows you the air push you desire.

NOTE:

Strongback is gray in color. make sure it’s

pinched between the grate and the feeder housing.

As shown below.

IMPORTANT:

Paddle should be

greased at least twice per year with standard grease

(see grease fitting position below)

. Grate gasket should

be applied to feeder housing.

WIRING:

Locate plug connections below, connect

the male and female plugs with matching letters

(example A.M. to A.F.)

connect C.M. to a 110 volt

wall outlet.

FEEDER ASSEMBLY

PARTS LIST

1. Auto Heat Control Box

2. Feeder Housing

3. Grate

4. Half Moon Feed Paddle

5. Plastic Wheel (Combustion Wheel)

6. Airmotor Tray

7. Cover Plate Bolt 1/4" x #20 x 2"

8. (4) #10/32 Nuts

9. Ball Joint Feed Arm

10. Feed Motor

11. Feed Motor Block

12. 1/2 Moon Feed Block

13. (2) 1/4" x #20 Wing Nuts

14. Strongback Gasket

15. Removable Feed Motor Tray

16. Airmotor / Combustion Motor

17. Grate Gasket 2' X Channel Gasket

18. Triple Plug Adapter

19. Paddle Plate (Note: 2 screws w/nut

3/8" x flat head not shown)

20. (2) 1/4" x #20 x 1" cap screws

21. Grease Fitting

22. 4' x 3/8" Rope Gasket

2

FIGURE 2

4

22

19

2

10

1

Hopper

Gasket

B.M.

B.F.

C.M.