21

Nov. 2006

MAINTENANCE

WARNING

REMOVE ALL POWER AT THE FUSED DISCONNECT DURING ALL

ELECTRICAL OR MECHANICAL SERVICING. DISCONNECT MUST BE

PROPERLY LOCKED OUT DURING MAINTENANCE OR SERVICE OF

EQUIPMENT.

DAILY INSPECTION

1.

Run through a full door cycle (open/close) and ensure smooth operation. Verify that the door

is not jammed or hanging up.

2.

Check the door fabric for any visible damage or unusual wear.

3.

Check all actuators for proper operation. If applicable, verify the automatic operation of the

door.

4.

Check the operation of safety photocells and bottom rail reset system.

QUARTERLY INSPECTION

1.

Inspect all hardware for proper tightness. Any loose hardware should be tightened. It is

recommended to apply a tread locker compound to any bolts that are coming loose. i.e. Loctite

242 (blue).

2.

Observe both open and close door limits. Ensure a proper floor seal is intact when the door is

fully closed. There should be no visible light seen between bottom rail rubber seal and floor. If

limits are out of adjustment, re-adjust according to the procedure outlined in the electrical

startup section of this manual.

3.

Inspect cables and pulleys for unusual wear. Ensure that either tensioning rope is not slack,

misaligned, or fraying. Replace worn or damaged components as necessary.

Summary of Contents for 350016-0000

Page 3: ......

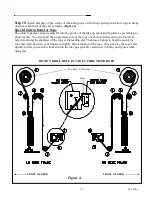

Page 12: ...12 Nov 2006 Figure 6 Figure 7 ...

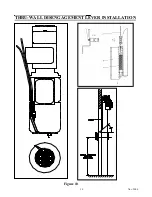

Page 14: ...14 Nov 2006 THRU WALL DISENGAGEMENT LEVER INSTALLATION Figure 10 ...

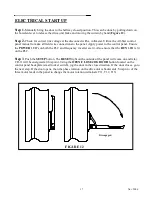

Page 20: ...20 Nov 2006 ...