Summary of Contents for ACS-50

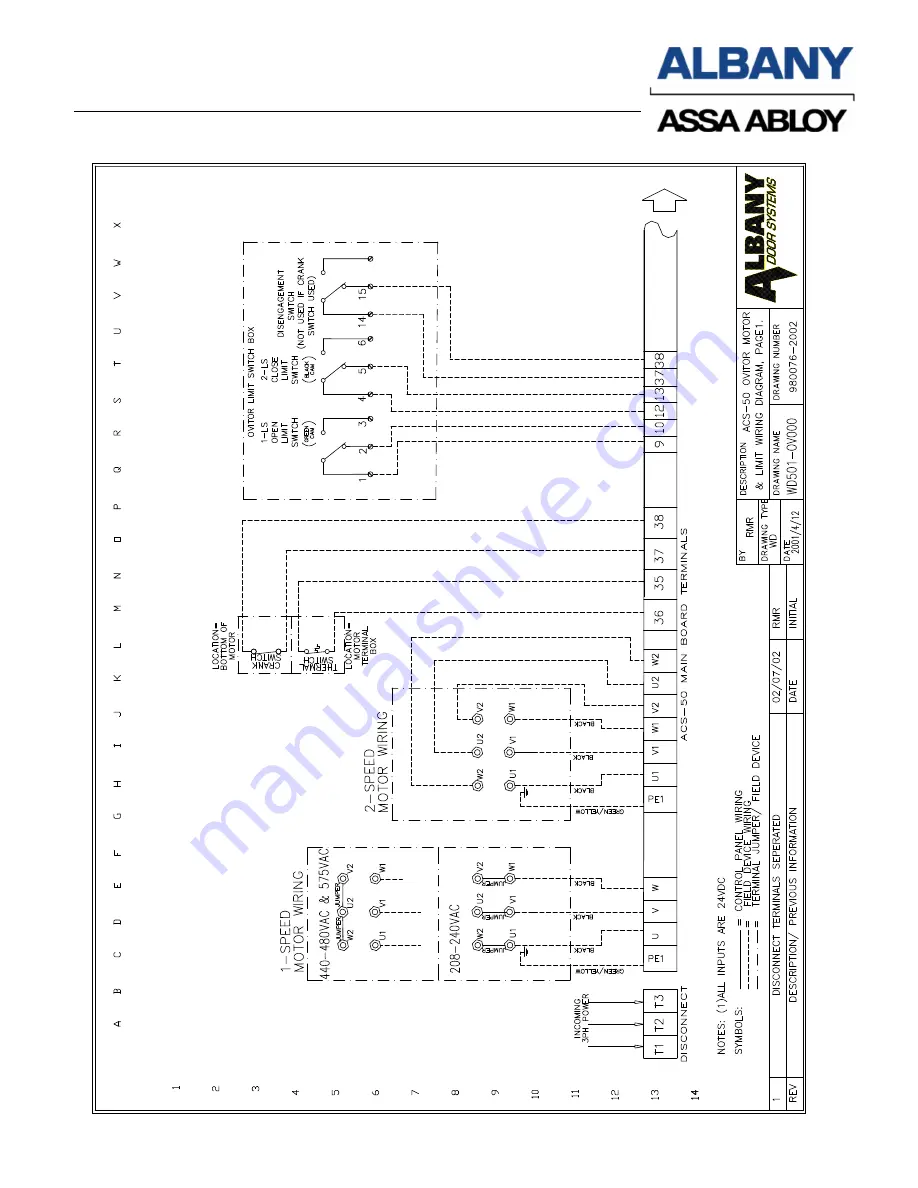

Page 5: ...Part 6410T0008 Rev F 5 ACS50 Control Panel Interior Single speed ...

Page 7: ...Part 6410T0008 Rev F 7 Figure 7 Single Speed Motherboard ...

Page 8: ...Part 6410T0008 Rev F 8 Figure 8 Two Speed Motherboard ...

Page 34: ...Part 6410T0008 Rev F 34 ACS50 Contactless Safety Edge Wiring if equipped ...

Page 35: ...Part 6410T0008 Rev F 35 Blanking Light Curtain Photocell Wiring ...

Page 36: ...Part 6410T0008 Rev F 36 ACS 50 Floor Loop 2Posi Selector Switch ...