Part N

umber

6410T0006

Version 4/23/2010

19

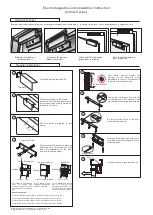

BOTTOM BEAM EQUIPPED WITH RAPID RESET™ OPTION. (Model 670 Only)

For the model 670, the door size or wind load may cause the door design t exceed a practical limit to this

technique. In this case, the Rapid Reset System (RRS) may be used. The mechanical installation is the

same as the SRD.

The Self Repair Device (SRD) option should be selected for interior doors or in exterior applications

where there are no heavy winds. The Rapid Reset System (RRS) option should be selected on exterior

applications where there may be heavy winds.

The Rapid Reset System (RRS) works as follows:

1.

Upon impact, a shock sensor located in the bottom beam will signal the door to stop immediately.

The driver should stop upon impact and then move away from the door opening.

2.

A blinking amber light on the control panel will indicate that the door is in need of being reset. A

sticker on the control panel will indicate the steps necessary to reset the door. The steps are as

follows:

A.

Return the fabric completely into the side frame guide. Either moving the bottom beam

manually back and forth to allow the curtain to slide back into the side frames, or open the

side frame covers and re-insert the curtain, to accomplish this task

B.

Push and hold the reset button for 3-5 seconds until the reset light goes out. The door has

been reset and is ready for operation.

Refer to the electrical manual for wiring details.

The model 670 design with the Rapid Reset System (RRS) is available with one or two wind bars ( one

per side). All wind bars must have straps to insure that in the event of impact, the wind bar will remain in

the channel. Strappless wind bars are not available with the RRS option. Wind bars are not available with

the Self Repair Device (SRD).

NOTE

The door should have an additional 4 inches in height for the wind bar to clear the door opening with

door equipped with the RRS.

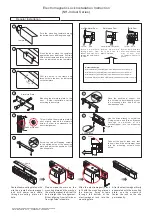

SPRING TENSIONING AND DOOR BALANCE

Step 1

Loosen the C-clamp and allow the intermediate pulley bracket to hang free.

Step 2

Using a come-a-long or similar joining tool, stretch the spring up to the middle hole of the

intermediate pulley bracket. Place the spring’s tang inside of the pulley bracket, insert bolt in the center

Summary of Contents for RAPID-ROLL 570

Page 9: ...Part Number 6410T0006 Version 4 23 2010 9 FIGURE 3 FIGURE 4 FIGURE 5 ...

Page 21: ...Part Number 6410T0006 Version 4 23 2010 21 FIGURE 17 FIGURE 16 FIGURE 18 ...

Page 38: ...Part Number 6410T0006 Version 4 23 2010 38 Figure 37 ...

Page 42: ...Part Number 6410T0006 Version 4 23 2010 42 Figure 39A ...

Page 50: ...Part Number 6410T0006 Version 4 23 2010 50 FIGURE 45 Figure 46 ...