Summary of Contents for UltraSecure 3000

Page 8: ...7 Manual 001451 Version 4 2 UltraSecure 3000 10 high up to 16 high ...

Page 9: ...Rev 9 27 2009 Manual 001451 8 Operation High Speed Doors UltraSecure 3000 up to 10 high ...

Page 26: ...25 Manual 001451 Version 4 2 ...

Page 27: ...Rev 9 27 2009 Manual 001451 26 Operation High Speed Doors ...

Page 28: ...27 Manual 001451 Version 4 2 ...

Page 29: ...Rev 9 27 2009 Manual 001451 28 Operation High Speed Doors ...

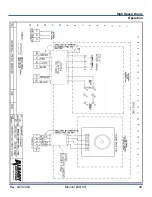

Page 36: ...35 Manual 001451 Version 4 2 ...

Page 37: ...Rev 9 27 2009 Manual 001451 36 Operation High Speed Doors ...

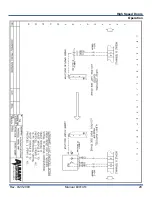

Page 38: ...37 Manual 001451 Version 4 2 ...

Page 39: ...Rev 9 27 2009 Manual 001451 38 Operation High Speed Doors ...

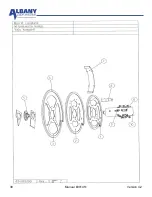

Page 40: ...39 Manual 001451 Version 4 2 ...

Page 41: ...Rev 9 27 2009 Manual 001451 40 Operation High Speed Doors ...

Page 42: ...41 Manual 001451 Version 4 2 ...

Page 43: ...Rev 9 27 2009 Manual 001451 42 Operation High Speed Doors ...