Manuale istruzioni

-FKC 65 UB

01/01/19 Rev: 1.0.0

52

16. SOUND EMISSION

The Leq equivalent level averaged over multiple processing cycles was detected with

Class 1 precision sound level meter as set out in IEC standards with constant fast-slow

reading, both from the position where the operator is located, and in positions surrounding

the machine being considered.

The measured value of the sound pressure at the level of the operator, is equal to Leq(A)

= 66 dB(A).

Summary of Contents for FKC 65 UB

Page 13: ...Manuale istruzioni FKC 65 UB 01 01 19 Rev 1 0 0 13 3 1 Dimensions...

Page 15: ...Manuale istruzioni FKC 65 UB 01 01 19 Rev 1 0 0 15 1 7 8 9 10 12 15 19 20 18 24...

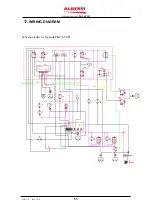

Page 27: ...Manuale istruzioni FKC 65 UB 01 01 19 Rev 1 0 0 27...

Page 41: ...Manuale istruzioni FKC 65 UB 01 01 19 Rev 1 0 0 41...

Page 54: ...Manuale istruzioni FKC 65 UB 01 01 19 Rev 1 0 0 54...