DLP-128

Replace Common Control Card (CCC)

5-26

3EM13853AD

Issue 02, July 2006

9

Observe output.

10

Determine AID of disks for CCC that is being replaced. Refer to table

.

11

Enter

RTRV-DISK;

to check state of all disks.

12

Observe output. Note state of disks A9 and A10.

13

Are disks in both CCCs in valid state? (One Disk A is IS,WRK, one Disk A is

IS,STBYH, one Disk B is IS,WRK, and one Disk B is IS,STBYH)

If yes, go to step

If no, go to step

14

Enter

ACT-DISK::

AID

::::ACTION=DEACTIVATE;

to deactivate disk in CCC being

replaced.

where: AID=Access Identifier of disk on CCC to be replaced (DISK-{A9, A10, B9, B10}).

When disks in CCC that is being replaced are deactivated, disks on CCC that is not

being replaced become active.

15

Repeat step

to deactivate other disk on CCC to be replaced.

16

Enter

RTRV-DISK;

17

Observe output. Note Primary State (PST) of disks that were deactivated.

18

Are PSTs of disks that were deactivated OOS-MA?

If yes, go to step

If no, go to step

19

Is state of disks in CCC not being replaced IS,WRK?

If yes, go to step

If no, go to step

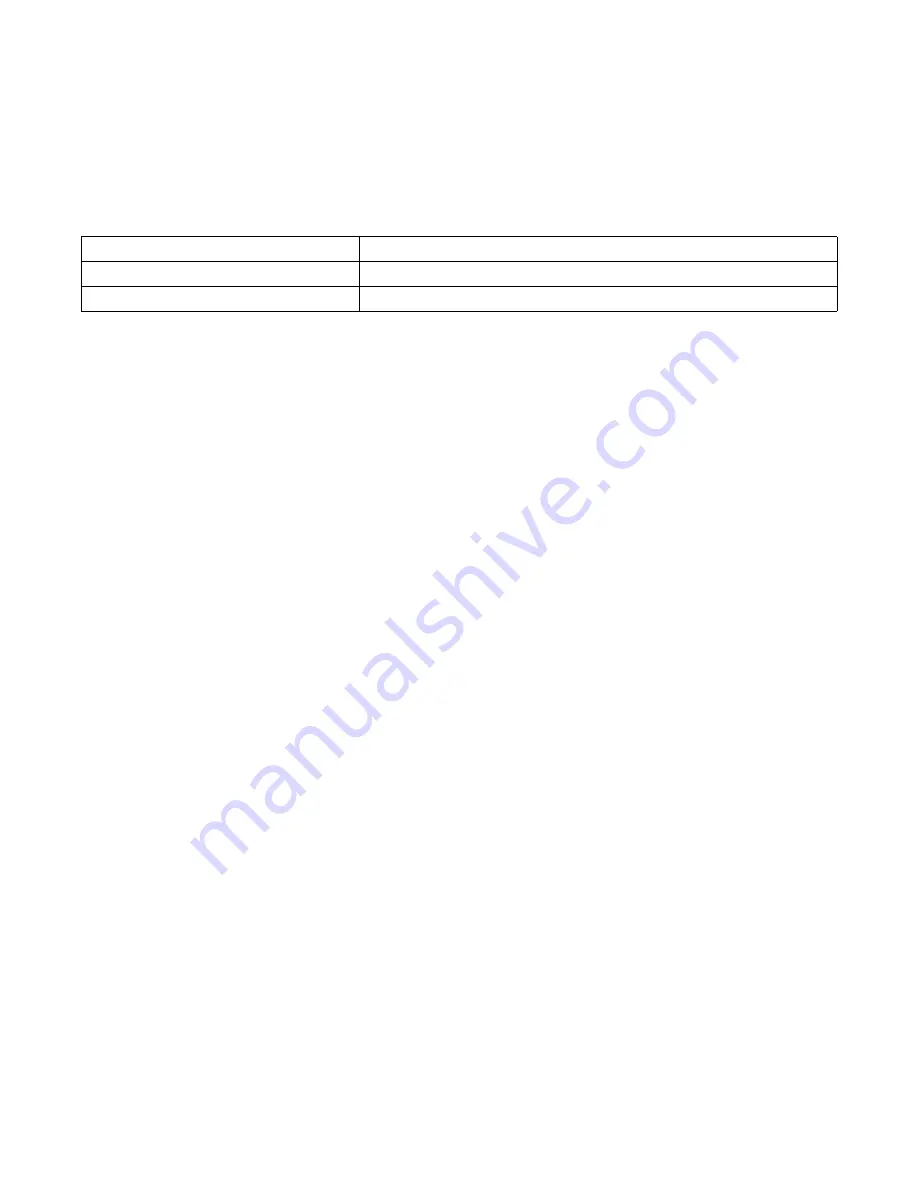

Table 128-A. CCC/Disk Relationship

CCC TO BE REPLACED

AID OF DISK (DISK AID)

CCC in slot 9

DISK-A9, DISK-B9

CCC in slot 10

DISK-A10, DISK-B10

Summary of Contents for 1677 SONET Link

Page 1: ...1677 SONET Link Maintenance and Trouble Clearing PN 3EM13853AD 02 R05 00 Issue 02 July 2006 ...

Page 9: ...3EM13853AD Issue 02 July 2006 Table of Contents vi ...

Page 13: ...3EM13853AD Issue 02 July 2006 List of Tables x ...

Page 17: ...3EM13853AD Issue 02 July 2006 Introduction 1 4 ...

Page 25: ...3EM13853AD Issue 02 July 2006 Introduction 1 12 ...

Page 29: ...3EM13853AD Issue 02 July 2006 Introduction 1 16 ...

Page 39: ...IXL 100 Task Index List 2 2 3EM13853AD Issue 02 July 2006 ...

Page 55: ...IXL 101 Alarm and Event Condition Clearing Procedures 2 18 3EM13853AD Issue 02 July 2006 ...

Page 57: ...IXL 102 Support Procedures 2 20 3EM13853AD Issue 02 July 2006 ...

Page 59: ...IXL 103 Equipment Replacement Procedures 2 22 3EM13853AD Issue 02 July 2006 ...

Page 61: ...IXL 104 Supporting Information 2 24 3EM13853AD Issue 02 July 2006 ...

Page 63: ...RTL 100 Preventive Maintenance Procedures 3 2 3EM13853AD Issue 02 July 2006 ...

Page 93: ...TAP 101 BKUPMEMP or BKUPMEMS Alarm 4 24 3EM13853AD Issue 02 July 2006 ...

Page 95: ...TAP 102 CFGFLT Alarm 4 26 3EM13853AD Issue 02 July 2006 ...

Page 97: ...TAP 103 IOC INT DF Alarm 4 28 3EM13853AD Issue 02 July 2006 ...

Page 99: ...TAP 104 CONTBUS 7 or CONTBUS 8 Alarm 4 30 3EM13853AD Issue 02 July 2006 ...

Page 101: ...TAP 105 CONTBUS MOS 1 or CONTBUS MOS 2 Alarm 4 32 3EM13853AD Issue 02 July 2006 ...

Page 105: ...TAP 107 SYNCSEC Alarm 4 36 3EM13853AD Issue 02 July 2006 ...

Page 107: ...TAP 108 FPSWUNLCK Alarm 4 38 3EM13853AD Issue 02 July 2006 ...

Page 111: ...TAP 110 Fan Faults CLFAN CTRLREAD CTRLWRITE INT 4 42 3EM13853AD Issue 02 July 2006 ...

Page 113: ...TAP 111 Fuse and Alarm Panel FAP Alarm 4 44 3EM13853AD Issue 02 July 2006 ...

Page 115: ...TAP 112 SNTP Alarm 4 46 3EM13853AD Issue 02 July 2006 ...

Page 119: ...TAP 114 CONTR TACC Alarm 4 50 3EM13853AD Issue 02 July 2006 ...

Page 121: ...TAP 115 INHPMMON Alarm 4 52 3EM13853AD Issue 02 July 2006 ...

Page 123: ...TAP 116 Resolve Craft Communications Loss 4 54 3EM13853AD Issue 02 July 2006 ...

Page 131: ...TAP 120 USTHRESHOLD Alarm 4 62 3EM13853AD Issue 02 July 2006 ...

Page 135: ...TAP 122 SYSDBG Alarm 4 66 3EM13853AD Issue 02 July 2006 ...

Page 137: ...TAP 123 IMPROPRMVL Alarm 4 68 3EM13853AD Issue 02 July 2006 ...

Page 143: ...TAP 125 DISK90 Alarm Drive A 4 74 3EM13853AD Issue 02 July 2006 ...

Page 145: ...TAP 126 TEMP Alarm 4 76 3EM13853AD Issue 02 July 2006 ...

Page 149: ...TAP 127 FWMISM Alarm 4 80 3EM13853AD Issue 02 July 2006 ...

Page 151: ...TAP 128 HWFAIL Alarm 4 82 3EM13853AD Issue 02 July 2006 ...

Page 153: ...TAP 129 INHMSG PM Alarm 4 84 3EM13853AD Issue 02 July 2006 ...

Page 155: ...TAP 130 INHSWPR Alarm 4 86 3EM13853AD Issue 02 July 2006 ...

Page 157: ...TAP 131 INHSWWKG Alarm 4 88 3EM13853AD Issue 02 July 2006 ...

Page 159: ...TAP 132 PWR Alarm 4 90 3EM13853AD Issue 02 July 2006 ...

Page 161: ...TAP 133 INT 1 Alarm 4 92 3EM13853AD Issue 02 July 2006 ...

Page 163: ...TAP 134 INT 19 Alarm 4 94 3EM13853AD Issue 02 July 2006 ...

Page 165: ...TAP 135 INT 2 Alarm 4 96 3EM13853AD Issue 02 July 2006 ...

Page 167: ...TAP 136 PRCDRERR Alarm 4 98 3EM13853AD Issue 02 July 2006 ...

Page 171: ...TAP 138 BATTERYLOW Alarm 4 102 3EM13853AD Issue 02 July 2006 ...

Page 173: ...TAP 139 CARD 8K DF and CARD INT DF Alarm 4 104 3EM13853AD Issue 02 July 2006 ...

Page 175: ...TAP 140 CFGNOSAVE Alarm 4 106 3EM13853AD Issue 02 July 2006 ...

Page 177: ...TAP 141 SRFLT SSCRAM Alarm 4 108 3EM13853AD Issue 02 July 2006 ...

Page 179: ...TAP 142 HLTHVER Alarm 4 110 3EM13853AD Issue 02 July 2006 ...

Page 181: ...TAP 143 IMPROPINS Alarm 4 112 3EM13853AD Issue 02 July 2006 ...

Page 183: ...TAP 144 IDROMREADER Alarm 4 114 3EM13853AD Issue 02 July 2006 ...

Page 185: ...TAP 145 MEM ACCESS DF Alarm 4 116 3EM13853AD Issue 02 July 2006 ...

Page 187: ...TAP 146 NO2KCLOCK Alarm 4 118 3EM13853AD Issue 02 July 2006 ...

Page 189: ...TAP 147 CLKALM Alarm 4 120 3EM13853AD Issue 02 July 2006 ...

Page 207: ...DLP 101 Module Mechanical Removal and Replacement 5 18 3EM13853AD Issue 02 July 2006 ...

Page 209: ...DLP 114 Handling Static Sensitive Devices 5 20 3EM13853AD Issue 02 July 2006 ...

Page 223: ...DLP 128 Replace Common Control Card CCC 5 34 3EM13853AD Issue 02 July 2006 ...

Page 237: ...DLP 131 Replace EDFA Card 5 48 3EM13853AD Issue 02 July 2006 ...

Page 241: ...DLP 132 Replace Fan Tray Assembly 15 RU Shelf 5 52 3EM13853AD Issue 02 July 2006 ...

Page 255: ...DLP 135 Replace OC n Line Card 5 66 3EM13853AD Issue 02 July 2006 ...

Page 267: ...DLP 137 Replace Timing Card TC 5 78 3EM13853AD Issue 02 July 2006 ...

Page 273: ...DLP 138 Remove Install Card Slot Adapter 5 84 3EM13853AD Issue 02 July 2006 ...

Page 277: ...DLP 141 Replace VT Switch Card VSC 5 88 3EM13853AD Issue 02 July 2006 ...

Page 283: ...DLP 144 Replace Transmux Card TMUX 5 94 3EM13853AD Issue 02 July 2006 ...