18

2480 Remote Intensifier Tooling Alcoa Fastening Systems

FILL AND BLEED PROCEDURE FOR

DISASSEMBLED TOOLS

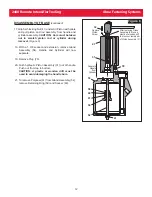

(Figures 11-13)

1. Before assembling Manifold Block onto Cylinder and

Handle assembly, push Air Piston (51) and intensifier

Piston Rod (52) assembly down to its full bottom

position. Use a nonmetallic rod to prevent damage to

handle bores and intensifier rods.

2. Fill handle pull and return ports with hydraulic fluid.

3. Install hose sleeves onto hoses and airline.

NOTE: Identify each end of one hose before

assembly.

Assemble the Manifold Block with Hoses

and Reservoirs onto the Handle.

4. Attach Fill Bottles with Connector (Figure 11) to ends

of each Hydraulic Hose (63). With Handle lower than

the end of the Hoses and Fill Bottles, connect Tool to

40psi air, and cycle the intensifier to remove all air

from the Hoses. Remove fill bottles and keep Hoses

vertical. Disconnect Tool from air supply.

5. Push tool Piston (4) into the full forward position and

hold tool upside down. Fill PULL and RETURN ports

with hydraulic fluid.

6. With tool still upside down, carefully attach Hydraulic

Hoses. NOTE: A slight amount of fluid will be lost

from the Hoses at this point. This is acceptable.

CAUTION: Use protection under Tool and Base to

catch or absorb any hydraulic fluid which may

drip or spill. See WARNING in Figure 11.

7. Attach plastic Handle halves (19), with Air Trigger

Assembly attached, to sides of tool.

8. Connect 60 psi air to the Cylinder and cycle the tool

and measure the specified stroke.

9. To properly pressurize the system follow all

instructions in the F

ILL AND

B

LEED

P

ROCEDURE FOR

A

SSEMBLED

T

OOLS THAT

N

EED

R

E

-

BLEEDING

section of

this manual.

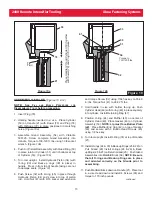

RETURN

PORT

PULL

PORT

Step 1

Push Air Piston (51) and

intensifier Piston Rod

(52) assembly down to

the full bottom position.

Air Piston (50)

Intensifier Piston

Rod (52)

Step 2

Fill handle PULL and

RETURN ports with

hydraulic fluid.

Figure 13

S

S

ER

ER

VICE

VICE

N

N

OTES

OTES