SFBTT20-IT BOBTAIL® Hydraulic Tool

(HK1121)

Alcoa Fastening Systems

8

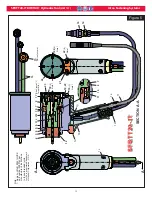

Load

Cell

Trigger

Switch

Test

Fastener

PHOTO - A

PHOTO - B

Tool Force

Tool Force

Reading

Reading

To decrease

Relief Valve pres-

sure, turn the

Relief Valve han-

dle gradually

counterclockwise;

turn clockwise to

increase pressure.

Relief

Relief

Valve

Valve

Fastener

Size and

Grade

Tool Force

(lbs)

Relief Valve

Pressure

(psi)

Powerig

PULL Pressure Setting

(psi)

Powerig

RETURN Pressure Setting

(psi)

Controller

Pressure Setting

(psi)i

1/2 inch

Grade 5

7800-8000

2700

7000

5000

2450

5/8 inch

Grade 8

20,500-21,000

6100

7000

5000

5850

12 mm

Grade 10.9

12,000-13,000

4250

7000

5000

4000

14 mm

Grade 10.9

16,000-17,000

5600

7000

5000

5350

16 mm

Grade 10.9

20,500-21,000

6100

7000

5000

5850

Table 1 - Tool Force and Pressure Settings

S

S

ETUP

ETUP

(

CONTINUED

)

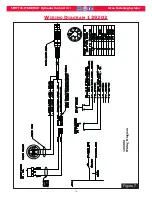

11. Set Pull and Return pressures on Powerig

using Huck Gage P/N: T-124833CE and

Table 1

.

12. Using a load cell

(see

PHOTO-A

)

or a skid-

more, and a test fastener in the tool, energize

the Powerig using a trigger switch. Adjust the

Relief Valve

(see

PHOTO - B

)

so the tool gen-

erates the Tool Force shown in

Table 1

below.

This is a direct force reading, not pressure. It

equals approximately the Relief Valve

Pressure shown in

Table 1

.

NOTE: It is

important to Release the Trigger while

adjusting pressure, then re-energizing to

re-check pressure. Otherwise, the reading

on the pressure display may be incorrect.

When the desired pressure is achieved,

reconnect the Controller Cord.

13. Tool #2 and Tool #3 - Set up the same way as

Tool 1.

14. Once the system is set up, Install test fasten-

er. Check to be sure that the fastener is

installed correctly. This can be checked by

inspecting the dimples on the collar flange. At

least one dimple should be marked by the

anvil. If not, add time to Timer #2 (Hold Timer)

in the Controller box, and test with fasteners

until the proper installation is achieved. See

“Set Point Adjustments” in

C

ONTROLLER

sec-

tion on the next page to adjust timer.