7

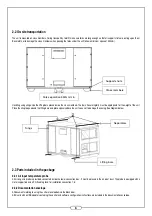

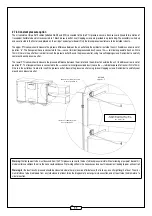

2.4 Unit Assembly

2.4.1 General information

Assemble the unit’s cross members on a fl at, stable surface (fl at surface for condensates).

It is advisable to install an anti-vibration device between the Unit’s legs and the frame (e.g.: pads or mats) and between the pipe fi ttings and the duct

system (e.g.: fl exible cuff) to dampen any vibration generated by the motorised fans.

During unit installation and connection of ducts and electrical cables, make sure not to block the access points so that internal operational components

can be easily extracted, thus enabling electrical connection of the unit.

Space required for maintenance: to enable fi lter replacement, the 2 side doors must be able to open to a min. of 90°. The central black door must be

able to open to 180° for access to switches and controls.

Provide the space and height required for connecting a siphon to drain the condensates from the exchanger and cooling coil. See section 2.8.1.

700

700

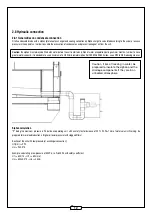

2.4.2 Exterior version

The Everest units have IPX4 protection against water damage and pitting. units destined for exterior use are equipped with a weatherproof cover. To

ensure protection against rain entering into the unit’s internal compartments, it is necessary to install a rain canopy (sold as an option) on the air inputs

and exhausts, if they are not equipped with gutters. Alternatively, we recommend installing on the exterior version, insulation dampers on the air input

and exhaust orifi ces.

Caution:

Installation of the weatherproof cover must comply with DTU 43.1, Chap. 5.4. The overall size of the unit is greater with the weatherproof

cover and canopy! To install the canopy, see section 2.7.2, for dimensions see section 3.2.

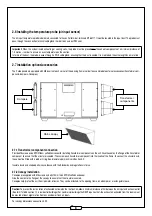

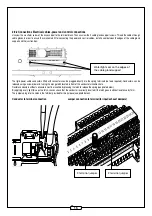

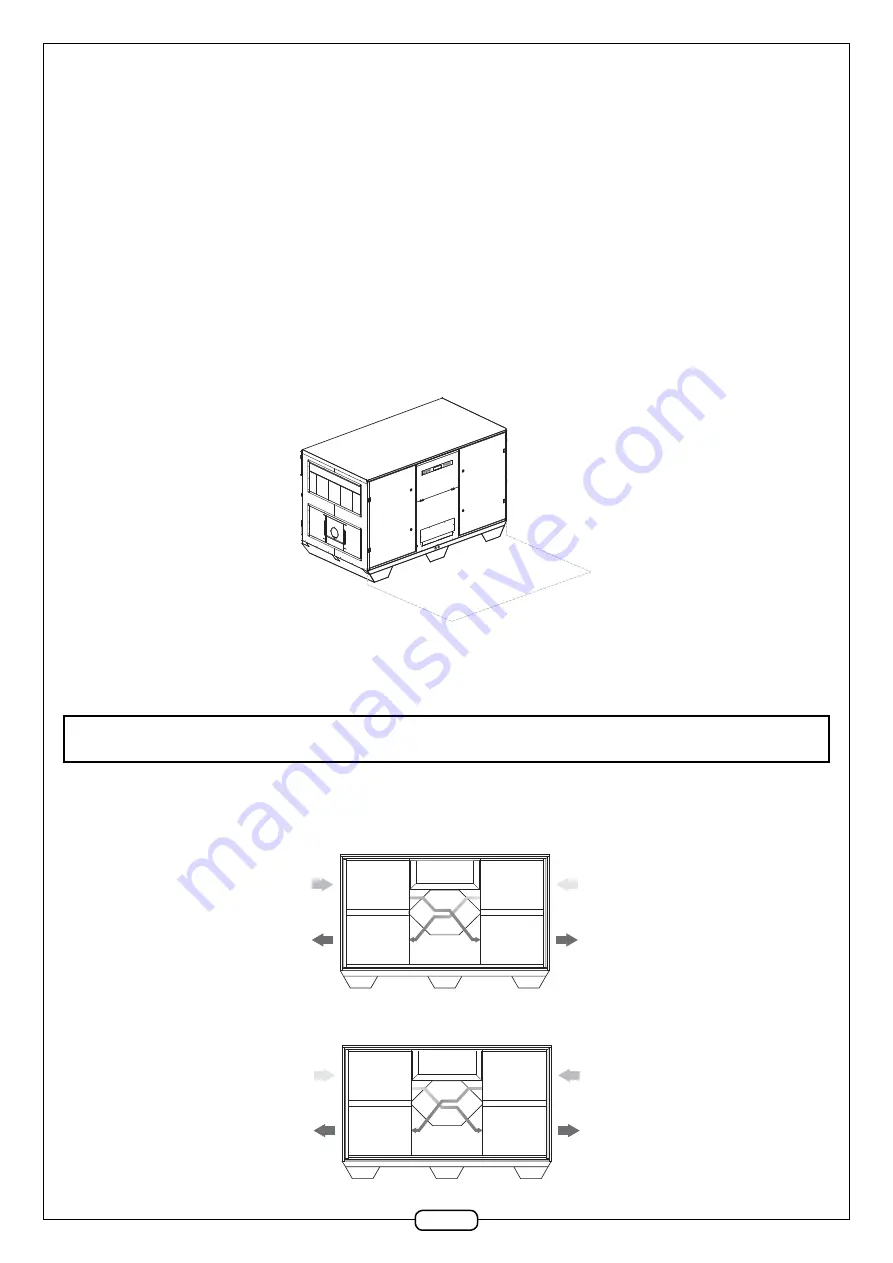

2.5 Direction of fl ow

There are right and left air fl ow versions

2.5.1 Right Version

Fresh Air

Discharge

Exhaust

Air Supply

Fresh air fl ow to the right

2.5.2 Left Version

Fresh Air

Discharge

Exhaust

Air Supply

Fresh air fl ow to the left