READ AND SAVE THESE INSTRUCTIONS

ZRT-PDIL / ZRT-PDIL-HP

AIRFLOW & ZONE CONTROL

PARALLEL DAMPER IN-LINE ZONE TERMINAL

IOM

*U.S. Pat. No. 9,759,442

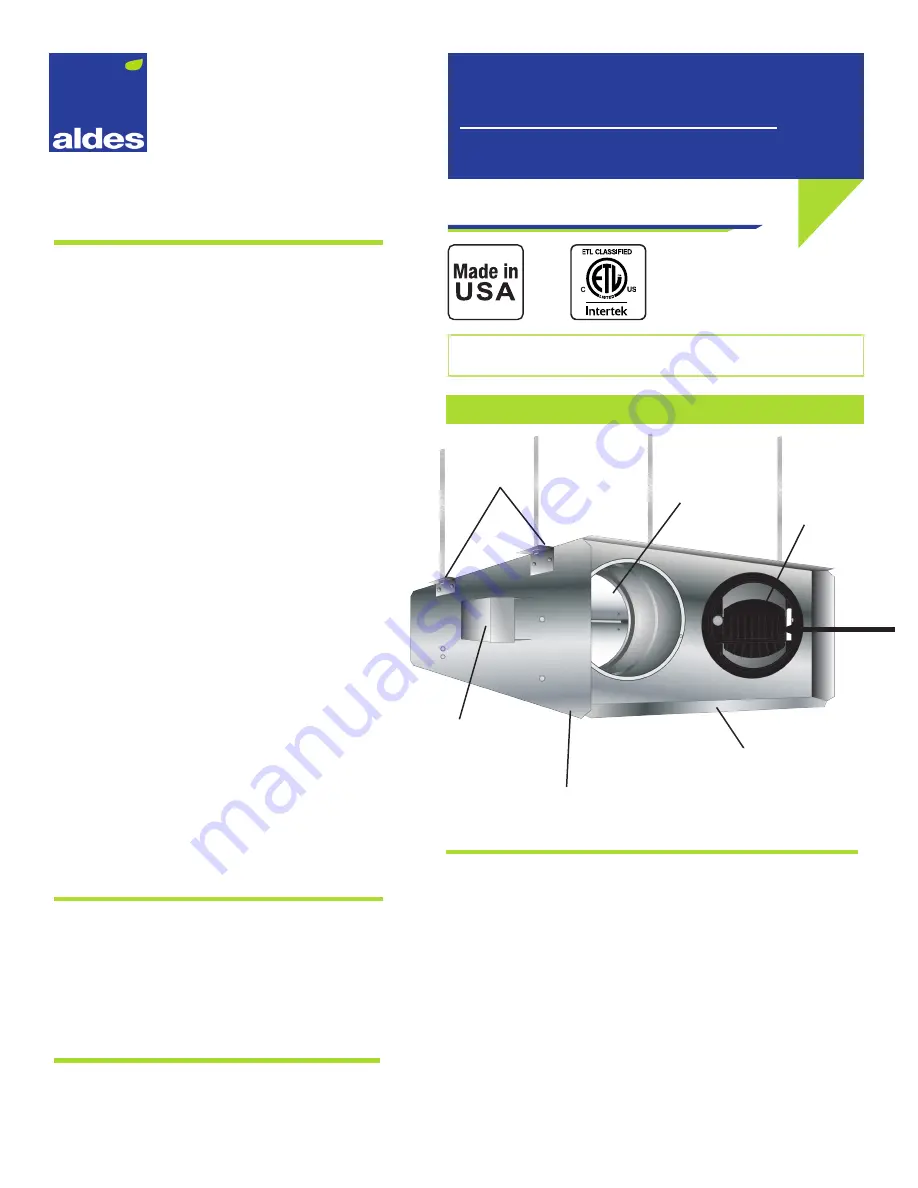

FIGURE 1 - MOUNTING

Integral

Continuous CAR

Flanges for attaching to

rectangular duct in a slip-type

duct connection

Power Connection

(24 VAC or 120 VAC)

to Motorized Damper

Motorized Damper

and Boost CAR

Screw-On Access Plate

Hanging Brackets

AIRFLOW

Description

Aldes Parallel Damper In-Line Zone Terminals

(ZRT-PDIL) are designed to introduce flexibility

and dynamic control to central supply or exhaust

ventilation systems. Used in both large and small

systems, the ZRT-PDIL regulates ventilation without

the need for individual fans or traditional VAV

terminal units.

Each ZRT-PDIL is a two-position, pressure-

independent terminal with a control damper to

regulate high limit on-demand airflow control and

integral passive regulators for automatic air balancing

of the continuous and boost airflow setpoints.

This unique combination provides flexible control

schemes without the need for expensive pneumatic,

electronic, or DDC control systems.

The ZRT-PDIL is primarily used for combination low-

flow indoor air quality ventilation or make-up air, and

on demand high-flow spot ventilation using the same

central exhaust or supply fan system. This is achieved

by integrating a minimum Constant Airflow Regulator

(CAR) in the terminal end panel and in-line with the

branch duct. The maximum airflow is controlled by

a series of 24 VAC or 120 VAC powered motorized

damper(s) and a secondary CAR airflow controller.

With the maximum-air motorized control damper

completely closed, the continuous CAR allows steady,

low-volume airflow control. (Continuous and Boost

Constant Airflow Regulators may be CAR-II or CAR3

depending on required airflow. See ZRT-PDIL CFM

Range for details).

When other ZRT-PDIL are activated for on-demand

control of high flow, the unpowered ZRT-PDIL will

maintain the specified continuous rate through the

pressure-independent CAR. Opening the ZRT-PDIL’s

control damper adds its calibrated boost airflow rate

to the continuous setpoint.

Mounting

The ZRT-PDIL/ZRT-PDIL-HP is intended to be installed

in-line in a duct system. It is provided with four (4)

mounting tabs that are suitable to suspend the unit

with threaded rods (not included). See Figure 1. The

unit should be installed in a location that provides

clearance for the access plate.

Maintenance

All components of the ZRT-PDIL/ZRT-PDIL-HP are

accessible through the opening provided by the

access plate.

Wiring

ZRT-PDIL/ZRT-PDIL-HP wiring needs to meet all applicable electrical

and building codes. If the electrical connection to the damper

motor wiring box is not accessible after mounting, there needs to

be enough slack (approximately 24”) in the electrical wiring leading

to the wiring box to allow the damper assembly to be removed

through the access opening. This will allow access to the electrical

connections from the access opening.

ZRT-PDIL/ZRT-PDIL-HP models are available with 24 VAC or 120 VAC

motorized dampers. 120 VAC wiring is shown in Figure 2 and 24 VAC

wiring is shown in Figure 3 (next page).