12

AFTER SALES SUPPORT

AUS

1300 884 987

www.medion.com.au

MODEL: MD 17329 PRODUCT CODE: 13651 05/2020

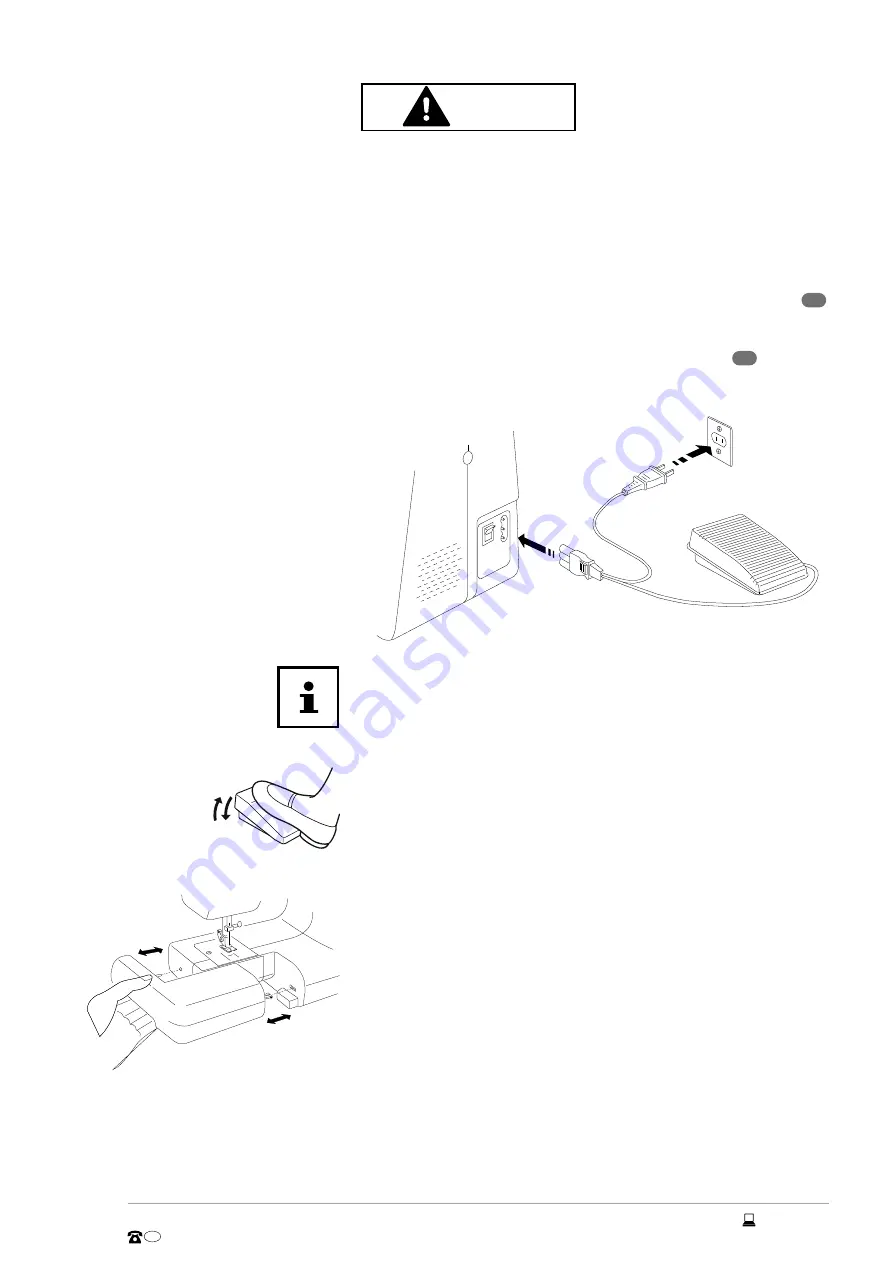

Electrical connections

CAUTION!

Risk of injury!

There is a risk of injury from accidental operation of

the foot control.

Once you have finished working or before you start

maintenance, always turn off the machine and the

power point and unplug the machine.

1. Plug the connector on the power cable supplied into the socket

9

on the machine.

2. Plug the mains connection into the mains power point.

3. Switch the sewing machine on with the power switch

10

. The

power switch turns both the sewing machine and the sewing light

on.

Use only the HKT72C foot pedal supplied with the

product.

Controlling the sewing speed

The sewing speed is controlled by the foot pedal.

The sewing speed can be changed by applying more or less pressure

to the foot pedal.

Attaching and removing the table extension

The machine is supplied with an attached work table.

−

The table extension is removed by pushing it carefully to the left.

−

To attach the table extension, carefully place the table extension

on to the machine and push it to the right until it audibly clicks into

place.

Summary of Contents for Stirling Black Edition MD 17329

Page 50: ...Version V1 4 ...