First use

16

www.isc-gmbh.info

GB

AFTER SALES SUPPORT

16

IRE

GB

IRE

0044 151 649 1500

0044 1890 946 244

First use

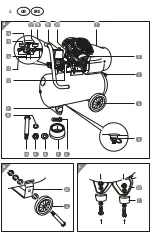

Checking the compressor and product contents

WARNING!

Risk of swallowing and choking!

Children must not play with plastic bags, wrappers and small parts. There is a

risk of being swallowed and suffocation.

− Keep children away from the compressor, small parts and the packaging

material.

− The compressor is not a children’s toy.

1. Lift the compressor out of the packaging with both hands.

2. Place the compressor on a level, stable surface.

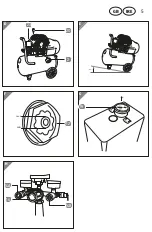

3. Check to make sure that the delivery is complete (see

fig. A

and

B

and

the list on p. 6

).

4. Check whether the compressor or the accessories exhibit damage. If this is the

case, do not use the compressor. Contact the manufacturer at the service address

specified on the warranty card.

5. To the extent possible, store the packaging until the warranty period has expired.

Preparations and assembly

The following assembly steps must be performed before using the compressor for the

first time. You will need two open-ended spanners or ring spanners with a width of

AF 14 and AF 17 as well as a flat-headed screwdriver for removing the transport caps.

Mounting the wheels

The wheels must be mounted before using the compressor for the first time. To do so,

proceed as follows (see

fig. B)

:

1. Place the back part of the compressor on a stable, slightly elevated base

(e.g. a tool box) so that the wheels

4

can be mounted on the wheel support

brackets

21

(see

fig. A

and

B

).

2. Insert the axle screw

10

through the wheel from the outside.

3. Put a washer

8

on the axle screw.

4. Insert the axle screw through the wheel support brackets on the compressor.

5. Put the second washer on the axle screw.

6. From the back, place the spring washer

11

on the axle screw.

7. With one hand, screw a nut

9

onto the axle screw.

Summary of Contents for Workzone WAC 3050/1

Page 4: ...B C A 4 5 1 2 20 19 3 13 18 14 16 15 7 8 9 10 6 7 12 21 11 22 17 7 4 4 GB IRE...

Page 5: ...H F G D E Max 10 min max 23 2 19 16 12 14A 14B 20 5 GB IRE...

Page 34: ...34 www isc gmbh info GB AFTER SALES SUPPORT 34 IRE GB IRE 0044 151 649 1500 00441890946244...

Page 37: ......

Page 38: ......

Page 39: ......