20

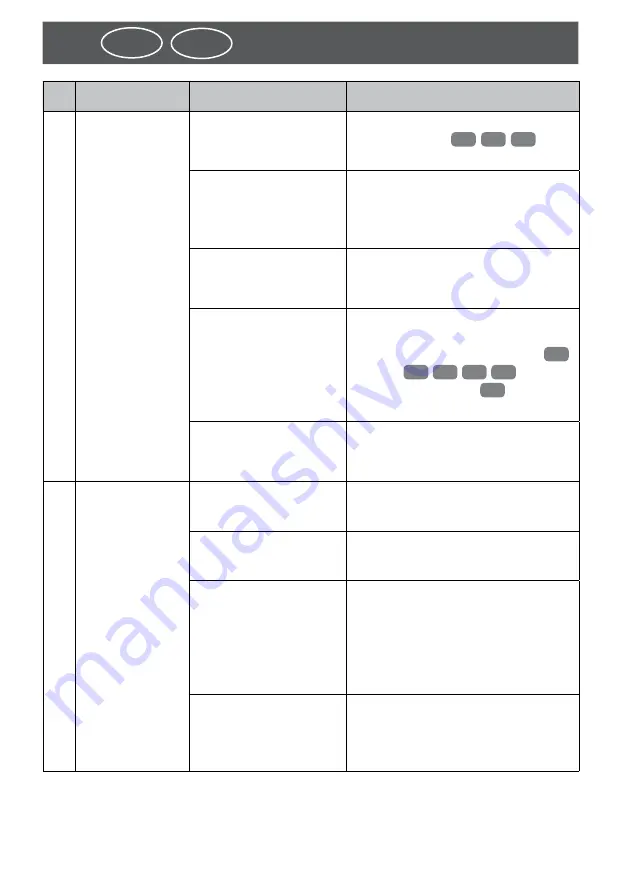

Troubleshooting

IRE

GB

Problem

Possible cause

Solution

1. The article was

not supplied

with com-

pressed air

or the quan-

tity was not

sufficient.

The wrong adapter

was fitted.

Check that you have fitted the

correct adapter

10

/

11

/

12

(see

chapter “Preparing the adapter”).

The adapter has not

been properly fitted on

or in the valve.

Check to make sure that the adapt-

er is properly seated. If applicable,

hold it firmly during operation to

prevent air from leaking.

The trigger for the tyre

fill gauge has not been

depressed enough.

Use the trigger to control the sup-

ply of compressed air.

The screw and plug

connections are not

properly connected.

Check to make sure that the screw

and plug connections of the

connec ting hose, tyre fill gauge

8

,

adapter

9

/

10

/

11

/

12

and

compressed air hose

4

are prop-

erly seated.

The non-return valve

or one of the gaskets is

broken or not tight.

Have the damaged part replaced

at a qualified workshop.

2.

The compres-

sor can not be

started.

The mains plug has not

been inserted properly.

Check to make sure that the mains

plug is properly seated.

The socket is not live.

Use another device to check the

socket.

The outside temper-

ature is too low. The

compressor will not

start if the ambient

temperature is below

+5 °C.

Do not operate the compressor at

an ambient temperature of under

+5 °C.

The motor has

overheated.

Let the motor cool off. If possible,

rectify the cause of overheating.

Make sure that the vents are not

obstructed.

Summary of Contents for WorkZone WZK 183

Page 4: ...A B 1 2 3 4 6 5 7 10 11 12 9 8 4 Overview GB IRE...

Page 5: ...C D G E F 1 2 5 Use IRE GB...

Page 24: ...24 IRE GB...