Visit our website at

www.alemlube.com.au

or

www.alemlube.co.nz

NSW/ACT

TEL: (02) 9677 1555

FAX: (02) 9675 1155

QLD/PNG

TEL: (07) 3204 9166

FAX: (07) 3204 1224

VIC/TAS

TEL: (03) 8787 8288

FAX: (03) 8787 8266

WA

TEL: (08) 9302 4199

FAX: (08) 9303 2095

SA/NT

TEL: (08) 8241 7111

FAX: (08) 8241 7011

NZ

TEL: (64) 9 447 1007

FAX: (64) 9 447 1008

14 of 16

MAINTENANCE

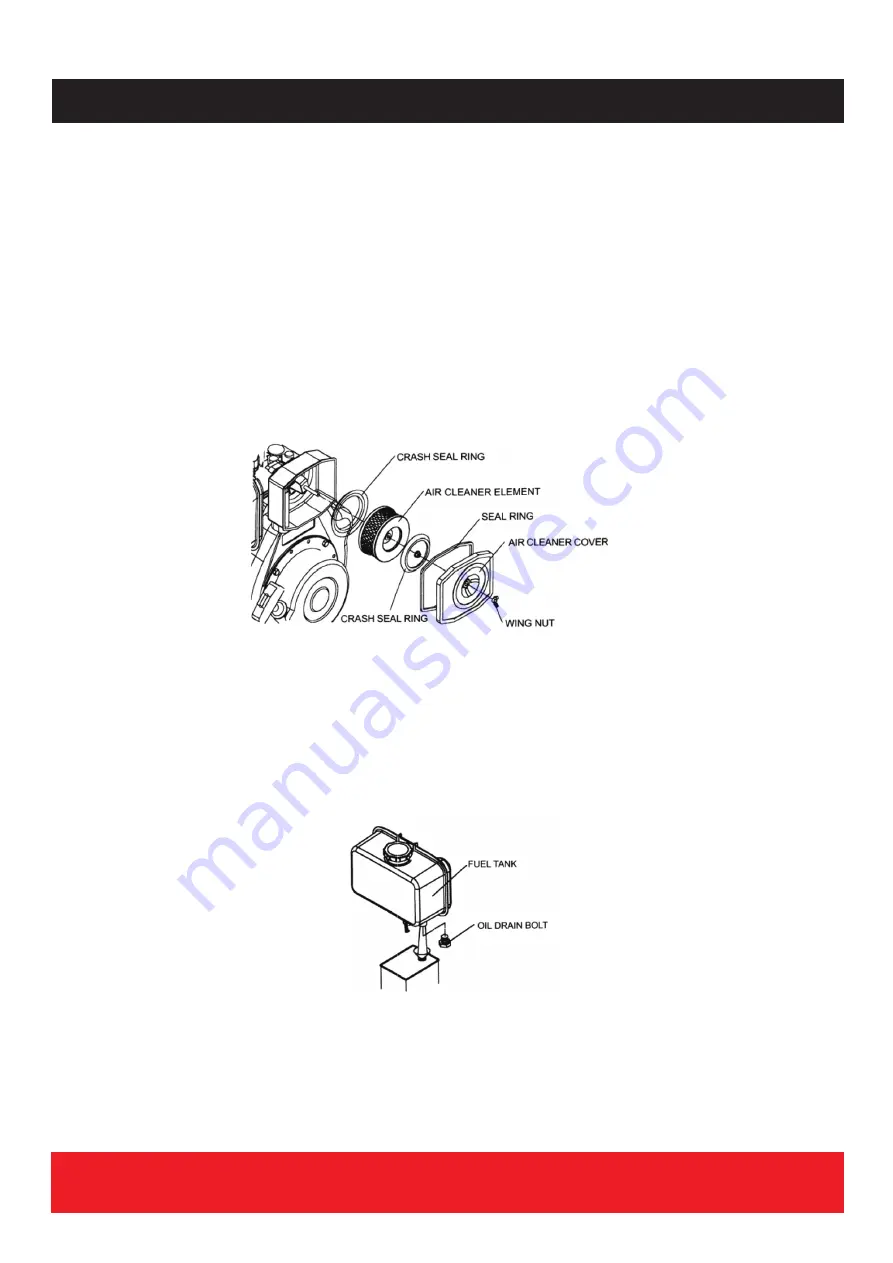

2) Air cleaner service

1) Remove the air cleaner cover by loosening the wing nut.

2) Wash the element in a non flammable or high flash point solvent and dry it thoroughly.

3) Soak the element in clean engine oil and squeeze out the excess oil.

4) Reinstall the air cleaner element.

5) Reinstall the air cleaner cover, then screw on the wing nut and tighten it securely.

3) Cleaning and replacing the fuel filter.

Remove the fuel filter from the fuel tank, then wash or replace it.

Clean: every 6 months or 500 hours.

Replace: every year or 1000 hours.

1) Drain the fuel from the fuel tank thoroughly.

2) Screw off two nuts in the fuel valve, remove the fuel filter from the fuel tank.

If the engine has been running, the muffler wil to cool before proceeding.

14

(1) Remove the air cleaner cover by loosening the wing nut.

(2)Wash the element in a nonflammable or high flash point solvent and dry it thoroughly.

(3) Soak the element in clean engine oil and squeeze out the excess oil.

(4) Reinstall the air cleaner element.

(5) Reinstall the air cleaner cover, then screw on the wring nut and tighten it securely.

3) Cleaning and replacing the fuel filter.

Remove the fuel filter from the fuel tank, then wash or replace it.

Clean: every 6 months or 500 hours.

Replace: every year or 1000 hours.

(1) Drain the fuel from the fuel tank thoroughly.

(2) Screw off two nuts in the fuel valve, remove the fuel filter from the fuel tank.

If the engine has been running, the muffler wil

to coolbefore proceeding.

cleaner cover by loosening the wing nut.

(2)Wash the element in a nonflammable or high flash point solvent and dry it thoroughly.

(3) Soak the element in clean engine oil and squeeze out the excess oil.

the air cleaner cover, then screw on the wring nut and tighten it securely.

Remove the fuel filter from the fuel tank, then wash or replace it.

(2) Screw off two nuts in the fuel valve, remove the fuel filter from the fuel tank.

If the engine has been running, the muffler will be very hot. Allow it

14

(1) Remove the air cleaner cover by loosening the wing nut.

(2)Wash the element in a nonflammable or high flash point solvent and dry it thoroughly.

(3) Soak the element in clean engine oil and squeeze out the excess oil.

(4) Reinstall the air cleaner element.

(5) Reinstall the air cleaner cover, then screw on the wring nut and tighten it securely.

3) Cleaning and replacing the fuel filter.

Remove the fuel filter from the fuel tank, then wash or replace it.

Clean: every 6 months or 500 hours.

Replace: every year or 1000 hours.

(1) Drain the fuel from the fuel tank thoroughly.

(2) Screw off two nuts in the fuel valve, remove the fuel filter from the fuel tank.

If the engine has been running, the muffler wil

to coolbefore proceeding.

cleaner cover by loosening the wing nut.

(2)Wash the element in a nonflammable or high flash point solvent and dry it thoroughly.

(3) Soak the element in clean engine oil and squeeze out the excess oil.

the air cleaner cover, then screw on the wring nut and tighten it securely.

Remove the fuel filter from the fuel tank, then wash or replace it.

(2) Screw off two nuts in the fuel valve, remove the fuel filter from the fuel tank.

If the engine has been running, the muffler will be very hot. Allow it