aleo solar GmbH

| Marius-Eriksen-Straße 1 | 17291 Prenzlau | Germany |

info@aleo-solar.com

Installation manual Ver. 4.8, 05/2021, en

Page 13 of 20

10.3 Clamp mounting for modules with Solrif® frame

HINWEIS

Avoid clamp mounting for modules with Solrif® frame. Only

mount these modules with the Solrif® mounting system.

You can also contact the aleo solar branch in your country.

They will provide you with information on mounting systems

which are already in use on a greater scale.

10.4 Screw mounting

10.4.1 Modules with standard frame

The aleo modules have mounting holes with a diameter of 9 mm.

10.4.2 Modules with Solrif® frame

Avoid screw mounting for Solrif® modules. Only mount Solrif®

modules with the Solrif® mounting system.

10.4.3 Tightening torque for screw mounting

For M8 stainless steel screws, use a maximum torque of 24 Nm.

6

10.5 Insertion mounting

10.5.1 Modules with standard frame

Observe the manufacturer’s instructions for the mounting system.

Use the earthing holes for the potential equalisation.

Although edge-to-edge mounting is possible (see also chap. 8.4.1:

„Intervals between modules with standard frame“), aleo solar

recommends mounting at intervals.

10.5.2 Modules with Solrif® frame

Only mount modules with Solrif® frame with the Solrif® mounting

system.

6

This applies to unlubricated screws with standard thread and strength

class of 8.8 (minimum breaking load 29.2 kN).

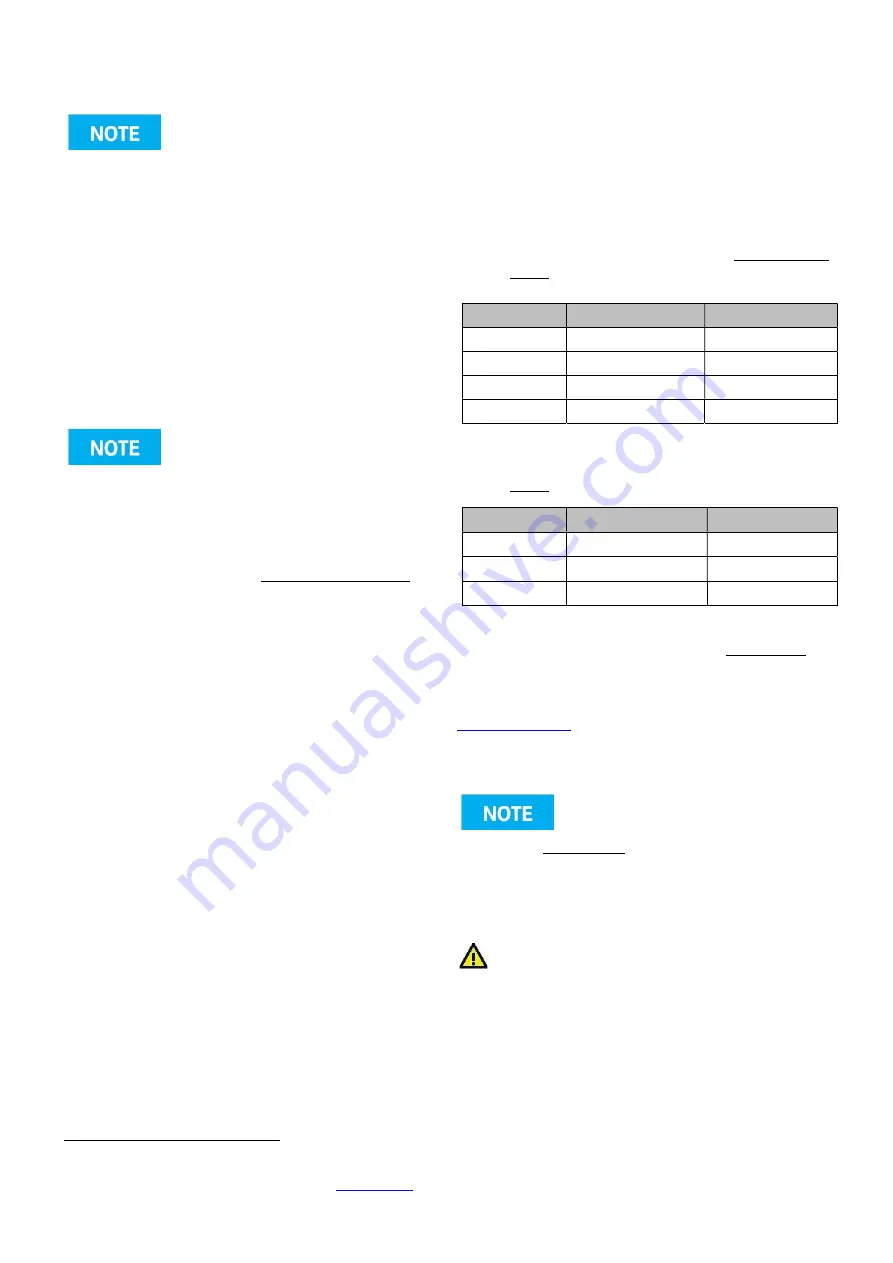

10.6 Load levels

A load can be a pressure load as well as a suction load. Loads from

snow and wind are grouped into several levels, which need to be

considered wherever the module is installed. Higher load levels

make the requirements for proper installation more stringent. The

values listed below assume an appropriate installation (see chap.

10.7: “Mounting drawings for modules with standard frame”).

10.6.1 Permissible loads for modules with standard frame

42mm

10.6.2 Permissible loads for modules with standard frame

35mm

10.6.3 Permissible loads for modules with Solrif® frame

Please observe the instructions from Schweizer for the mounting of

modules with Solrif frame. You can find the manual on the website

from Ernst Schweizer AG Metallbau or on aleo solar website:

www.aleo-solar.com

.

10.6.4 Snow load

For snow loads above 3900 Pa, suitable measures must be taken to

ensure that slipping snow loads do not damage the lower module

frame.

Possible measures are: snow hooks or module holder, in the middle

of the lower frame part.

CAUTION!

These measures only serve as a support for the frame and not as an

additional fastening point. Clamps fixing the frame are therefore

not suitable for this purpose!

For snow loads above 3900Pa, aleo recommends horizontal instal-

lation with clamping on the long side.

Load level

Permissible pressure

Permissible suction

Load level I

2400 Pa

2400 Pa

Load level II

3900 Pa

2400 Pa

Load level III

5400 Pa

2400 Pa

Load level IV

8000 Pa

5400 Pa

Laststufe

Zulässiger Druck

Zulässiger Sog

Load level I

1400 Pa

1400 Pa

Load level II

3900 Pa

2400 Pa

Load level III

5400 Pa

2400 Pa