5

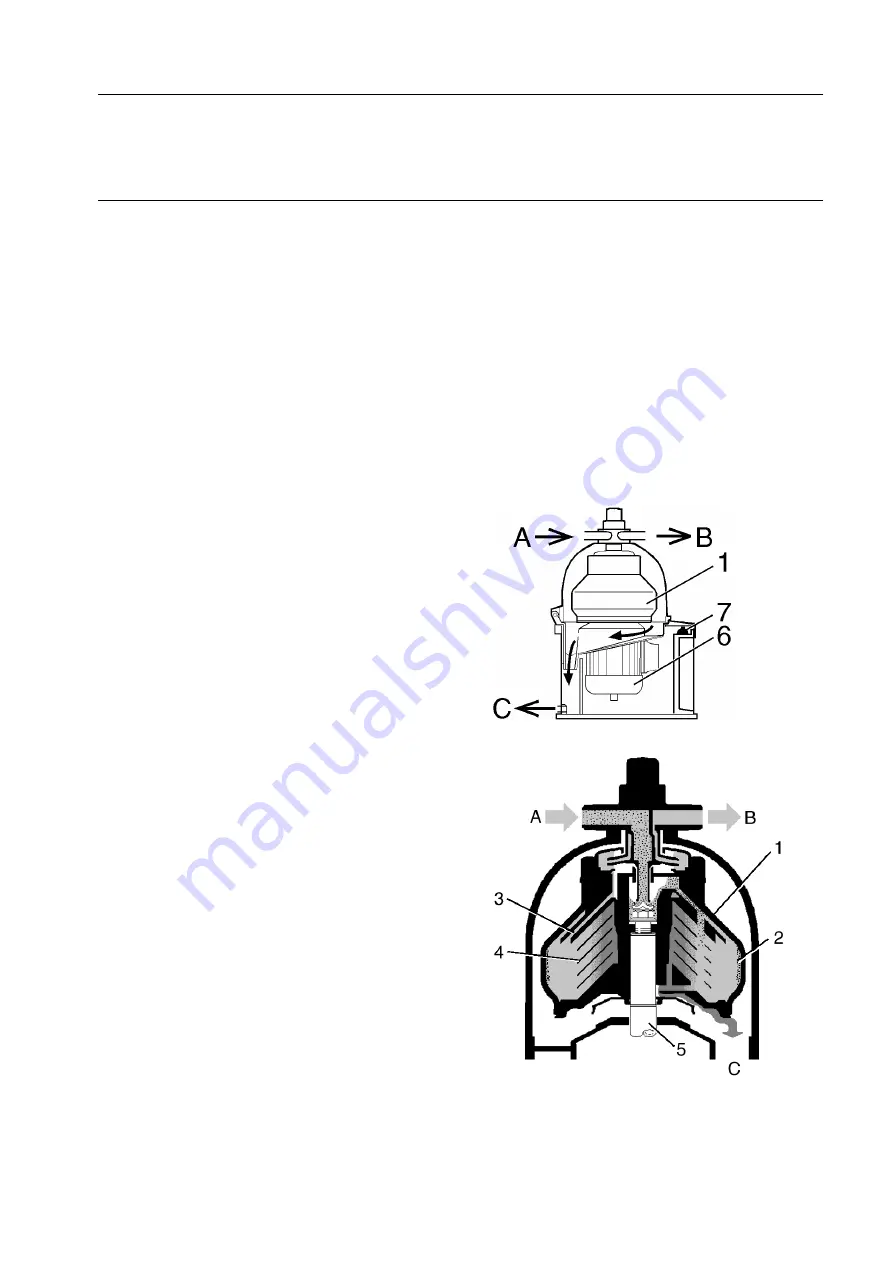

Working principle of the

separator

Dirty liquid continuously enters at (A) and flows into the bowl (1). The bowl rotates at high speed

generating powerful centrifugal forces. As the liquid rotates with the bowl, the liquid (heavy phase)

and solid particles moves towards the periphery of the bowl. The particles (2) are deposited on the

bowl wall, while the cleaned liquid enters the channels (3) and leaves the bowl (B) at a constant

pressure. The discs (4) in the bowl improves the cleaning efficiency during the separation process.

The oil (light phase) is forced towards the centre of the bowl and then leaves through the underside

of the bowl at (C) down into the collecting tank.

The speed of the electric motor (6) driving the bowl spindle (5) is regulated by a frequency converter,

which by that eliminates any use of a transmission such as a gear or a belt. The converter also acts

as a brake when the separator is stopped.

The bowl (1) and motor (6) are suspended on vibration dampers (7).

A.

Liquid inlet

B.

Clean liquid outlet

C.

Oil outlet to collecting tank

1.

Bowl

2.

Particles (sediment)

3.

Channels from bowl to outlet B

4.

Conical discs

5.

Bowl spindle

6.

Electric motor

7.

Vibration dampers

G0450581

G0519231

19

Summary of Contents for Alfie

Page 6: ......

Page 10: ...2 Application ...

Page 18: ...4 Description of main parts ...

Page 20: ...5 Working principle of the separator ...

Page 30: ...6 Control Cabinet ...

Page 47: ...9 Maintenance Dismantling G04491c1 See comments on opposite page 47 ...

Page 53: ...9 Maintenance G0449671 53 ...

Page 54: ...9 Maintenance G0449681 54 ...

Page 60: ...11 Lifting instruction ...

Page 61: ...12 Diagrams 12 1 Electrical system Alfa Laval ref 9014733 Rev 7 61 ...