8

Trouble shooting

8.8

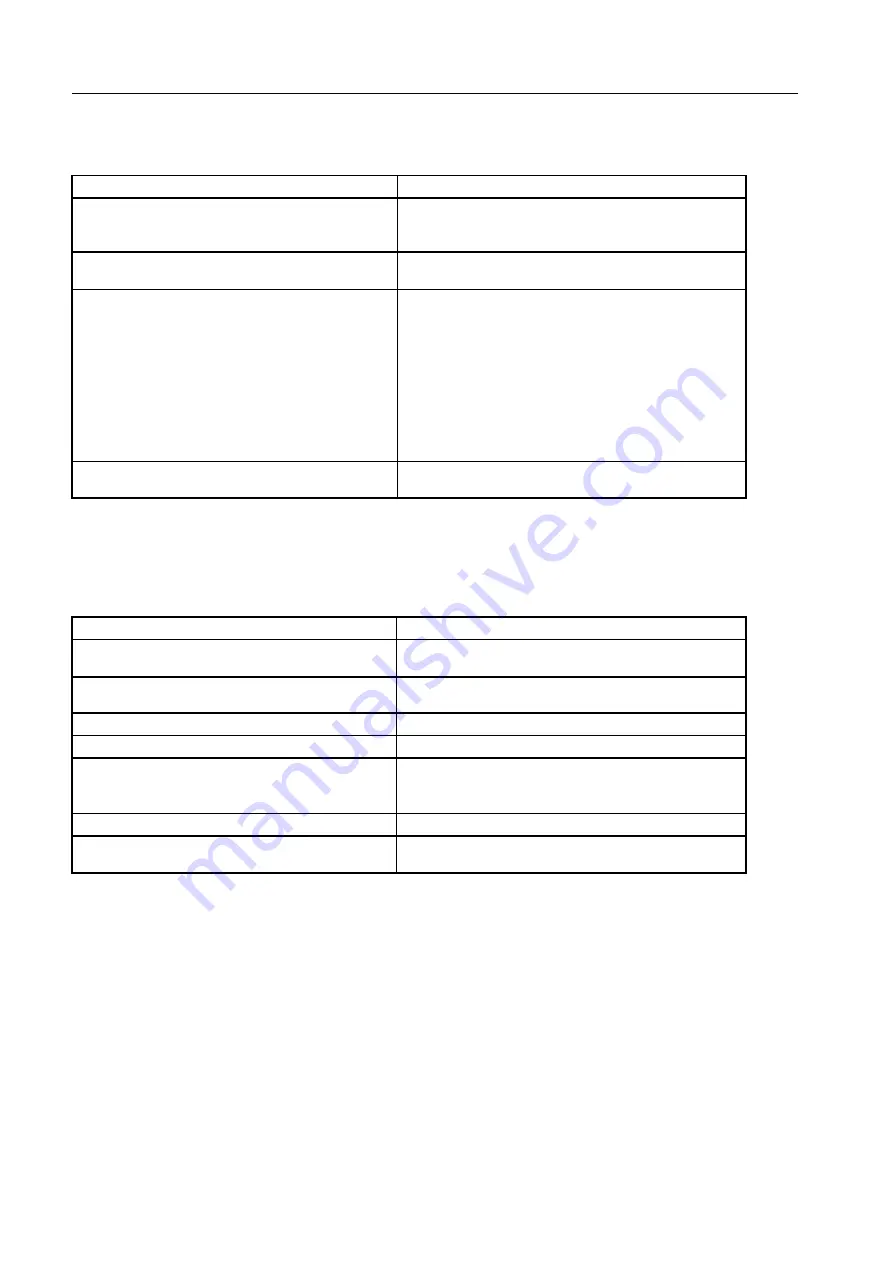

Flow too low

Possible cause

Action

Impeller in pump worn or broken

Replace impeller, See

impeller and mechanical seal for pump on page

55

Counter pressure at outlet too high

Reduce the counter pressure with the regulating

valve (100 - 180 kPa is recommended)

Leakage caused by incorrect assembly

•

The three screws fastening the bowl

hood or the paring disc knob (the upper

part of the separator) are not completely

tightened.

•

Dismantle and check the separator bowl

parts. Especially check that no O-rings are

missing, are defective or incorrectly fitted.

Ensure that the separator is assembled

correctly.

Separator or pump rotates in wrong

direction

Check power supply cables.

8.9

No flow either through clean oil outlet or through

drain to collecting tank

Possible cause

Action

Separator or pump stopped

Check function, see

and

Inlet and outlet hoses for pump wrongly

connected

Interchange the hose connections

Strainer before separator clogged

Clean strainer

Separator disc stack clogged

Clean separator bowl and disc stack

Air leakage on suction side between liquid

tank and pump

Check that the inlet of the suction device is

below surface in tank. Check that couplings are

correctly fitted.

Impeller attachment to nave is loose

Replace impeller, see

The sleeve fastened to the motorshaft for

the pump is loose

Tighten the lock screws, see illustration, pos.

14 & 15 on page

55

40

Summary of Contents for Alfie

Page 6: ......

Page 10: ...2 Application ...

Page 18: ...4 Description of main parts ...

Page 20: ...5 Working principle of the separator ...

Page 30: ...6 Control Cabinet ...

Page 47: ...9 Maintenance Dismantling G04491c1 See comments on opposite page 47 ...

Page 53: ...9 Maintenance G0449671 53 ...

Page 54: ...9 Maintenance G0449681 54 ...

Page 60: ...11 Lifting instruction ...

Page 61: ...12 Diagrams 12 1 Electrical system Alfa Laval ref 9014733 Rev 7 61 ...