16

If sawdust or small – crumbled pellets are put into the funnel-shaped part of the stove i.e. the fuel tank, these may

block the pellet (fuel) feeding. Such pellets may cause the electric motor driving the pellet feeding mechanism to

burn out, or they may lead to damages to the electric motor reducer. If you see any such small, crumbled pellets at

the bottom of the pellet tank or at the bottom of the screw conveyor when the tank is empty, vacuum them with a

vacuum cleaner by inserting the vacuum cleaner hose through the openings of the pellet grate.

9. CONNECTION OF THE HYDRAULIC INSTALATION

IMPORTANT!

-Connection of the furnace to the hydraulic installation can be performed by qualified technician

ONLY, and in accordance with the present legislation of the country in which the installation is

performed.

ALFA PLAM disclaims any responsibility in case of material or physical damage, or in case of

malfunction, if the above-mentioned recommendation were not implemented.

Furnace is designed for both central heating for one storey and central heating for multiple storeys.

Furnace is prepared for closed heating system. All installations should be in compliance with SRPS regulations

(Serbian technical regulations and standards).

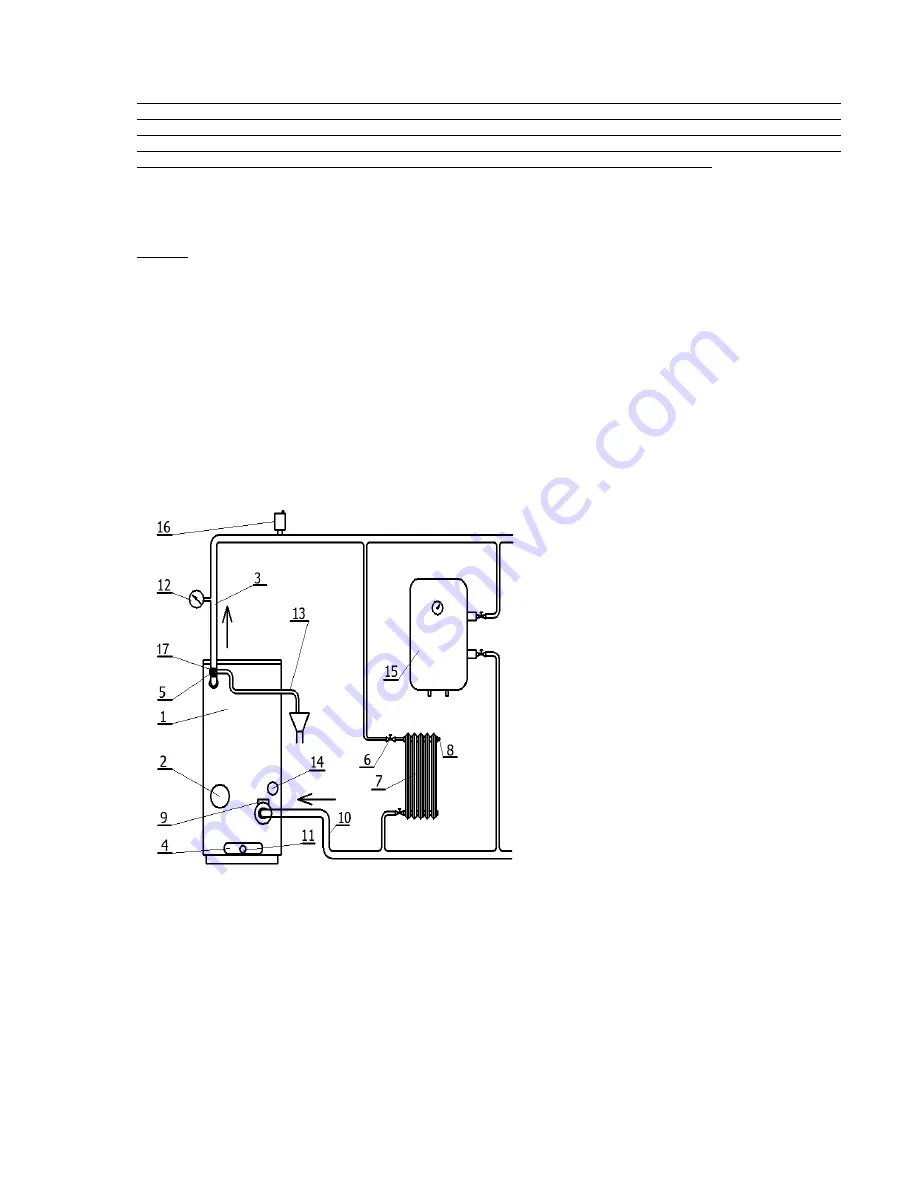

CONNECTING THE HYDRAULIC INSTALLATIONS

Back side of a boiler with all connections is shown in Fig. 19.

1. The COMMO Stove

2. Chimney connector

3. Distribution pipe

4. Expansion container (in the stove)

5. Safety valve (in the stove)

6. Radiator valve

7. Radiator

8. Breather valve

9. Circulation pump (in the stove)

10. Return pipe

11. Charging and discharging tap (in the

oven)

12. Thermo hydrometer

13. Drain pipe from the safety valve

14. The feeding tube of the air to be

combusted

15. Boiler