2

The heating devices (hereinafter referred to as the “stoves”) of ALFA PLAM (hereinafter referred to as ALFA

PLAM) are made and tested in accordance with the safety measures of the applicable regulations of the

European Community.

This Manual is intended for the stove users, installers, operators and persons responsible for the

maintenance of the stoves shown on the first page of the Manual.

If you have any questions related to this Manual, please contact the stove manufacturer or an authorized

service centre. In such a case, you should always state the number of the paragraph or chapter related to

the respective subject, i.e. the unclear subject.

Any printing, translation and reproduction, even partial, of this Manual is subject to the approval of ALFA PLAM,

which means that the said activities must be approved by ALFA PLAM. The technical information, figures and

specifications in this Manual must not be provided to any third party.

IMPORTANT WARNINGS!

IMPORTANT: The connection of the device to the power supply installation must be compulsorily

performed by qualified and authorized persons in accordance with the valid legal regulations.

This device has not been foreseen for application by persons (including children) with reduced physical,

motor and mental abilities or persons with limited knowledge and experiences without the presence of

persons responsible for their safety i.e. care.

Children must not play with these types of devices.

DUAL COMBUSTION SYSTEM

The flame obtained by the normal combustion of wood in the stove emits the same quantity of carbon dioxide (CO

2

)

that would be released as a result of the natural decomposition of wood.

The quantity of carbon dioxide (CO

2

) obtained by the combustion or decomposition of plant mass corresponds to

the quantity of carbon dioxide (CO

2

) that plant mass is capable of obtaining from its surroundings and transforming

it into oxygen for air and carbon of the plant during its whole life.

The use of non-renewable fossil fuels (coal, oil, gas), contrary to what happens with wood, releases into the

atmosphere enormous quantities of carbon dioxide (CO

2

) accumulated for millions of years, thus causing the

greenhouse effect. The use of wood as fuel is therefore perfectly balanced with the environment because wood as

renewable fuel is in ecological harmony with nature.

These goals are completely accomplished through the principle of clean combustion and this is why the designs of

the ALFA PLAM products are based on this principle.

What does clean combustion mean and how does it take place?

The control and adjustment of primary air and the introduction of secondary air generate, i.e. cause secondary

combustion or the so-called post-combustion that produces the secondary flame which by its nature is brighter and

stronger than the main or primary flame. The addition of new oxygen (through the introduced air) enables the

additional combustion of gases that were not completely combusted. This significantly increases the thermal effect

and decreases the harmful emissions of carbon monoxide (CO) because the incomplete combustion is reduced to a

minimum. These are the basic characteristics of the stoves and other products of ALFA PLAM.

0.0 TECHNICAL CHARACTERISTICS OF THE STOVE

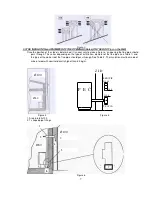

1. Dimensions:

-Width...........................................................................................................................................................590 mm

- Depth........................................................................................................................................................672 mm

-Height......................................................................................................................................................1222 mm

2. Diameter of the forge hood connection............................................................................................................80 mm

3. Diameter of the external air intake……..........................................................................................................100 mm

4. Height from the floor to the forge hood connection axis................................................................................380 mm

5. Maximum power…….....................................................................................................................................21.5 KW

8. Maximum consumption..................................................................................................................................5.0 kg/h

9. Degree of utilisation with maximum power.......................................................................................................94,3%

10. Minimum power……......................................................................................................................................7.0 KW

13. Minimum consumption.................................................................................................................................1.7 kg/h

14. Degree of utilisation with minimum power........................................................................................................92 %

15. Minimum draught...............................................................................................................................................5 Pa

16. Optimal draught...............................................................................................................................................12 Pa

17. Heating volume……...............................................................................................................................280-350 m

3

18. Capacity of the funnel-shaped fuel tank...........................................................................................................45 kg

14. Maximum operating time with a full tank……….................................................................................................30 h

15. Minimum operating time with a full tank………....................................................................................................9 h

16.Max allowable working pressure……………………………………………………………………………….……1,9 bar

17.Class of boiler EN 303-5:2012……………………………………………………………………………………..……...5