32

16. SECURITY MEASURES

Furnace is equipped with following safety devices:

-PRESSURE REGULATOR

Controls the pressure in the chimney. It stops transport spiral for the pellet when the outlet is clogged or when it

faces pressure (draught)

-FLUE GASES TEMPERATURE SENSOR

Measures the temperature of the flue gasses and allows furnace ignition o stops it if the flue gasses temperature

goes bellow set value.

-CONTACT THERMOSTAT IN THE FIREBOX OR ON THE SCREW FEEDER CASE

When a temperature exceeds safety values, furnace immediately shuts down.

- CONTACT THERMOSTAT IN THE BOILER

When a temperature exceeds safety values, furnace immediately shuts down

-WATER TEMPERATURE SENSOR

When water temperature gets close to 85ºC, sensor runs cooling cycles or automatically shuts the furnace down

using “ECO-STOP” option, in order to avoid blocking the temperature sensor.

-ELECTRICAL SAFETY

Furnace is protected from power surges with standard fuse located on control panel on the rear side of the furnace.

Rest of the fuses are located on the rear side of the furnace in order to protect motherboard (integrated cards and

heat exchanger cards).

-FLUE GASSES FAN

If the ventilator stops, motherboard blocks the pellet feed and emits alarm signal.

-HELICAL GEARED MOTOR

When helical geared motor stops working, furnace continues to work until the flame does not extinguish and until

the minimum cooling level is not reached.

-TEMPORARY OUTAGE

After short outage, furnace automatically starts cooling process.

-NO IGNITION

If during ignition there is no flame, furnace automatically changes to alarm status.

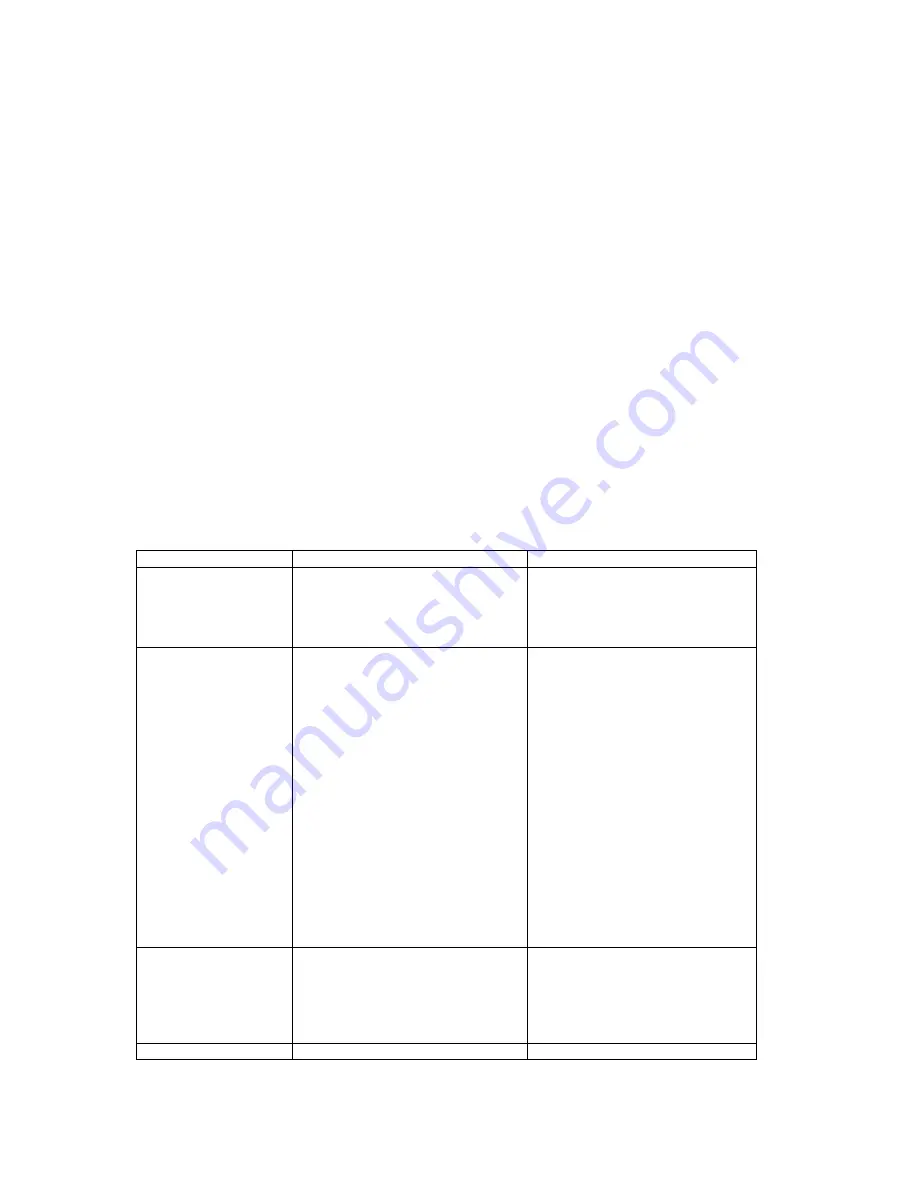

17. MALFUNCTION - CAUSES - SOLUTIONS

PROBLEMS

POSSIBLE CAUSES

SOLUTIONS

Wood pellets are not

in the firebox, in

combustion

chamber.

1. Wood pellet reservoir is empty.

2. Transport spiral is blocked.

3. Helical geared motor is broken.

4. Electric card is broken.

1. Fill the reservoir.

2. Empty the reservoir and unblock

the spiral – screw feeder

3. Replace helical geared motor

4. Replace electric card

Fire is not burning or

furnace

automatically shuts

down.

1. Wood pellet reservoir is empty.

2. Combustion chamber is not filled

with wood pellets.

3. Safety temperature probe

activation.

4. Hatch is not properly closed or

sealing cord is worn.

5. Inadequate wood pellets.

6. Poor supply of wood pellets.

7. Combustion chamber is filthy.

8. Chimney is clogged.

9. Interference or malfunction on

pressure stat.

10. Smoke fan motor is broken.

1. Fill the reservoir with wood

pellets.

2. See previous solution.

3. Let the furnace cool down and

then turn it on again. If the problem

persist, contact technical

department.

4. Close the hatch or replace

sealing cord.

5. Change the type of wood pellets

and choose one with

manufacturer’s approval.

6. Check dosage and settings.

7. Clean the combustion chamber

following instructions manual.

8. Clean the chimney.

9. Replace pressure stat.

10. Check the motor and replace it

if needed.

Furnace works for

several minutes and

then shuts down.

1. Ignition phase is not over.

2. Temporary outage.

3. Chimney is clogged.

4. Interference or malfunction on

temperature probe.

5. Spark plug is damaged.

1. Repeat ignition.

2. See previous instruction.

3. Clean the chimney.

4. Check or replace the probe.

5. Check or replace the sparkle

plug.

Wood pellets form

1. Lack of air for combustion.

1. Clean combustion chamber and