5

− The flue pipe used by another heat generator (water heaters, stoves, fireplaces, kitchen stoves, etc.),

− To the air exhaust system (grids, vents, etc.), even if the system is inserted in the pipe discharge.

DANGER

It is prohibited to install air circulation (draught) shut-off valves (flaps, valves that may prevent air circulation i.e. that

may prevent draught).

CAUTION

If the smoke discharge path produces poor draught i.e. poor air circulation (if the path has numerous bends,

inappropriate smoke discharge end, narrowing, etc.), the smoke discharge can be bad, i.e. inappropriate.

The smoke discharge system functions on the basis of the negative pressure and mild pressure of the flue pipe. It is

very important that the smoke discharge system is sealed. This requires the application of a pipe smooth inside.

When the flue pipe is to be placed through the walls and roof, the plan and structure of the room should be

thoroughly analysed and studied first, so that the pipe may be placed properly in accordance with the fire prevention

standards.

First, it should be ensured that there is sufficient combustion air in the room where the stove is located. Occasional

inspection is recommended to ensure that combustion air is properly supplied to the biofuel combustion chamber.

The stove operates on 230 V – 50 Hz. Ensure that the electric cable is not entangled under the stove, that it is away

from hot places and that it cannot come in contact with any sharp edge that could cut it. If the stove is electrically

overloaded, this may shorten the service life of the electronic parts of the stove.

Never turn off power supply by pulling out the plug while flames are still burning in the stove. This may

jeopardize the proper operation of the stove.

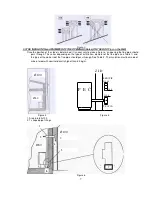

3.2 THE SMOKE DISCHARGE SYSTEM

The smoke discharge must be executed in accordance with the existing standards. The flue pipe should be

thoroughly sealed. See Figures 1 to 7.

For smoke discharge, classic brick chimneys can be used, or chimneys may be made of pipes that must be

thoroughly insulated (double wall) and sealed in order to prevent condensation in them.

The discharge pipe must not be connected with other systems of any type, such as the systems for discharging

smoke from the combustion chamber, exhaust grid or air distribution systems, etc. Furthermore, the flue pipe must

not be located in closed or semi-closed rooms such as garages, narrow corridors, under closed huts or any other

place where smoke may appear. When the stove is to be connected to the flue piping, a professional chimney

sweep should be called to verify that there are no even tiniest cracks or fissures in the chimney. If the smoke

discharge chimney has any cracks, the flue pipe must be wrapped in new material in order to ensure proper

functioning.

For this purpose, rigid pipes made of non-ferrous steel (with a minimum thickness of 1.5 mm) can be used, or pipes

made of stainless steel (with a minimum thickness of 0.5 mm).

The smoke discharge system (chimney) made of metal pipes must be grounded in accordance with applicable

standards and legal regulations.

Grounding is prescribed by the law.

This grounding connection must be independent of the stove grounding.

The flue pipe must be made in compliance with the standards regarding the dimensions and materials used for its

construction (Figure 1).

A) Wind resistant chimney top

B) Maximum cross section of 15 x 15 cm or a diameter of 15 cm, maximum height of 4-5 m.

C) Seal

D) Inspection – control opening.

Flue pipes in bad condition or made of inappropriate material (asbestos cement, galvanized sheet metal, etc. with

coarse and rough or porous surfaces) are illegitimate and they jeopardize and hamper the proper operation of the

stove.

Smoke can be discharged through a classic flue pipe (see the figures below) provided that the following regulations

are met:

− Check the maintenance condition of the flue pipe or the chimney. If the discharge flue pipe is old, it should be

replaced by a new one. If the chimney is damaged, it should be repaired or refurbished by inserting a steel pipe

properly insulated with mineral wool.