5

- If a cupboard is installed above the stove, the minimum distance between the stove hob and the cupboard

should be at least 70cm.

- Flammable materials (for example wallpapers, frames, doors etc.) from the flue should be at a distance of at

least 20cm. This distance may be reduced if thermal insulation is placed on the flue pipe and the temperature

of the surrounding objects does not exceed 80°C.

- The stove should be installed in horizontal position or slightly elevated from the back side (3-4mm).

5. FLUE INSTALLING

Review the unpacked stove and become familiar with the parts of the stove and the accessories, and

especially pay attention to the following:

- The special channels of the firebox door, the ashtray, the cover for cleaning and the hob frame should have

pigtails with no asbestos that seal well and do not allow uncontrolled air intake.

- The combustion regulator (thermostat) with regulation knob (fig.1 pos.10) should properly open and close the

regulator flap (fig.1 pos.19).

- The ember holder (fig.1 pos.13) should be properly placed in its bearing and should be easily open.

The flue connection (plug), that is delivered together with the stove and is placed in the drawer for wood,

should be set and screwed on the openings of the plug carrier (hob) or on the opening on the lateral side. The

existing cap must be previously removed and the same screws for connecting plugs should be used.

WARNING:

If Your flue is not the best or it is with suspicious quality, we recommend that You install a flue connection on

the plug carrier (from the top), and not on the side.

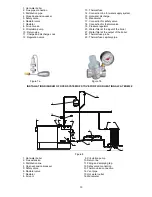

The flue reaches its rated power if the flue draft is 20Pa. We recommend the following flue sizes with which

this draft is obtained:

Stove

Denotement

Rated heating power

(kW)

Flue height (m)

6

7

8

9

10

ALFA TERM 20

Brown coal

wood

Dimensions of light surface (mm.)

22,8

22,9

145x200

145x145 145x145

145x145

145x145

- Proper flue and meeting other requirements set out in the material that follows are a prerequisite for flawless

functioning of the stove.

- The flue connection should be installed with uplifting.

- Horizontal flue pipe pieces longer then 0,5m should have an uplifting of 10

towards the flue.

- The flue extension, flue pipes and the flue must not be narrowed.

- All connections as well as the flue must be well sealed, with no soot

and grime in flue pipes.

- The flue should be protected from cold (it should be heat insulated). This especially applies for flues made of

sheet metal and flues built

on external walls.

- Flue pipes that do not have thermal insulation and do not stand vertically, must not be longer then 1,25m.

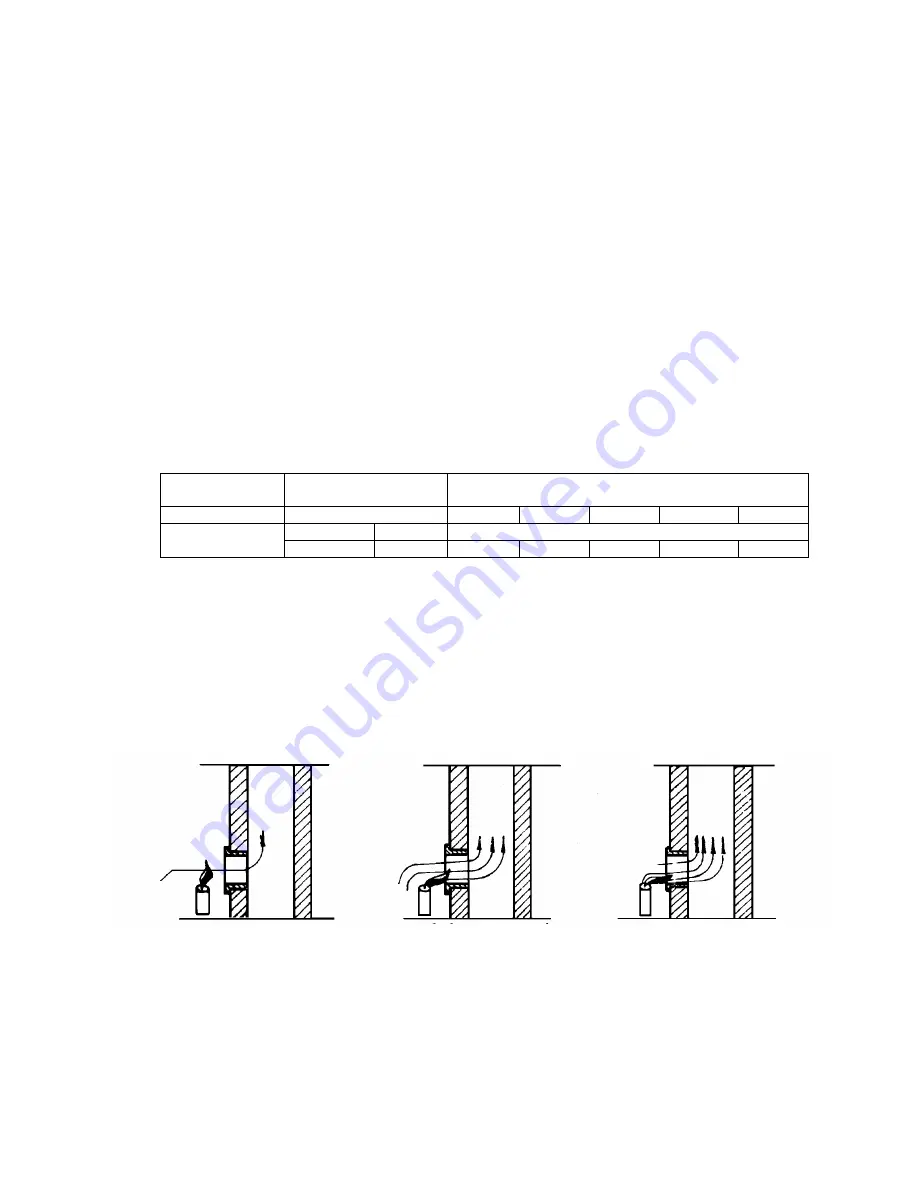

Check of the draft strength is performed by using candles (fig. 2).

slight draft

good draft very strong draft

Figure 2

The flue is functioning well if it satisfies the following conditions (fig. 3):

- It protrudes above the roof top (ridge) at least 0,5m.

- It is higher than the neighboring house that is close to the flue, a tree or some other barrier.

- It is in the internal walls of the house or it is well insulated if it is in the external walls.

- The extension should be closely connected to the flue if it is being extended.

- The flue pipe should not be inserted deeply in the flue opening as this reduces the space for smoke output.

- All other unnecessary openings as well as the door for cleaning should be well closed (sealed) so that so

called “false” air would not be created.